"Algoma Steel Inc., based in Sault Ste. Marie, Ontario, is Canada's third largest integrated steel

producer. Revenues are derived primarily from the manufacture and sale of rolled steel products,

including hot and cold rolled sheet and plate." [algoma]

|

| James Yarduk posted Algoma Steel Corporation, Sault Ste Marie Ont. Canada approx. c.1932 Some structures included in photo, Ore Dock, Blast Furnaces 1-4 Open Hearth Steelmaking plants , Rail & Merchant mills & Coke Oven batteries. |

|

| 1965 |

|

| Gabina Onthe Road posted, cropped paddled out to get a pic ...Algoma Steel , crafting Canadian coils |

|

| Mario Briglio Jr posted #7 Blast Furnace Sault Ste. Marie, Ontaio, Canada. When the fall sun hits just right the furnace shines finally with a new color. |

|

| Algoma-history May 1975 Algoma’s No. 7 blast furnace goes into operation. The 315 foot high furnace was designed to produce 5,000 tons of iron per day, replacing No. 3 and No. 4 blast furnaces. |

|

| Wayne Jolicoeur posted Inside Algoma Steel's Rail Mill in other years. |

|

| Ryan Powley posted #2 shop at Algoma steel, just chugging along! |

|

| Lucio Pezzotti posted No . 7 Blast Furnace Algoma Steel Sault Ste. Marie Ontario Canada. When it was commissioned in 1975 it was the largest furnace in the British Commonwealth producing 5000 tons per day. [Some comments indicate that they now aim for 7000 and that the record was 9000.] |

|

| Mario Briglio Jr posted April 2019 Algoma Steel in Sault Ste. Marie, Ontario Canada. #7 Blast Furnace. One of the first casts after a furnace recover from stack plate cuts that caused a furnace chill. This cast was sent to the slag pit as the iron chemistry was not good enough for torpedos. It took a lot of lancing with O2 pipe to make this connection. Richard Allison: The iron was probably full of silicon. We would pile sand all over the trough and both sides of the trough and sand the slag runner to the pit. Usually extra coke, extra limestone and lighten up on pellets until the furnace got back to normal. That limey slag was so oozy and sometimes you have to chase the lance pipe back into the taphole to keep it open and then that mess would pile up in the slag runner. None of this would make a good shift for the casthouse crew. I would think a labor gang would be on hand too. I am glad I am too old to do that.... Richard Allison: Algoma 7 used to be a fine furnace back in the 70s. |

|

| James Yarduk posted Algoma Steels, Direct Strip Production Complex, 2 strand Thin Slab-Caster. From molten steel to finished coils in one continuous process. (Photographer: unknown) [I wondered if someone could go from molten steel to rolled coils with no reheats.] |

|

| Tyson Breckenridge posted, cropped #7 Algoma |

|

| Graphic from algoma-about |

|

| James Yarduk posted Algoma Steel, Sault Ste Marie, Ontario. Canada Open Hearth steelmaking furnace taps into stopper controlled ladle in the 1940's. Open hearth furnaces at Algoma ran from approx. 1907-1974 when they fully converted to 5 oxygen vessels at 2 steelmaking shops. |

|

| David Kaye posted Cuyahoga unloading at Algoma Steel. 1-7-21 James Torgeson shared |

|

| Comments on James' share |

|

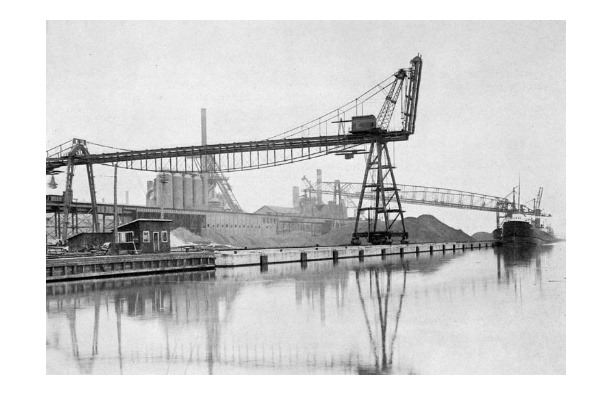

| James Yarduk posted Algoma Steel (c.1918) Vessel slip, Ore dock with Blast furnaces 1, 2 & 3 and furnace charging highline |

|

| Mike Eernisse posted, cropped Michipicoten unloading taconite pellets at Algoma steel mill James Torgeson shared |

Hayden Marcel Rollin-Taylor posted three photos with the comment:

Algoma Steel's No.3 Blast furnace started operations in 1911 it was rebuilt in 1963 and refitted to run off natural gas.In 1928 an explosion in the No. 3 Blast Furnace left five people injured and one person dead; rubble from the explosion flew as far as a quarter of a mile away.With No. 6 completed in July of 1953. Blast Furnace No. 7 was opened in May of 1975 and replaced the aging No. 3 and 4 furnaces.

Hayden Marcel Rollin-Taylor: You wont see #6 back online anytime soon either. So who knows whats gonna happen. Stockpile and re line

|

| 1 |

|

| 2 |

|

| 3 |

|

| Andre Leveszue posted |

Construction of #7 Blast Furnace at Algoma Steel in 1973.

Sault Ste. Marie Ontario Canada

Aaron Allard: Old #6 in behind to the right. Still standing, although idle...

James Yarduk: Aaron Allard Bf 3 decommissioned beside 6...then 4&5 going strong at that time...but they didn't quite make the photo.

Hayden Marcel Rollin-Taylor: First heat was blown into it in may 1975. One of the first of its kind with a "no belltop" charging system.

|

| James Yarduk posted Algoma Steel 12" Merchant Mill. (circa -1918) This facility was later modified to an 18" inch Merchant Mill which ran until approx. the 1980's. (est.) The Merchant Mill was part of the Rail and Structural complex at Algoma, which rolled it's last beam in April of 1999. Zeke Pezel: Yup. I spent time there too. Hated the 25 hz lighting. Felt like i was in a disco.Donald McMillan: When Algoma Steel closed down the Rail and Structural mill , the production of rails in Canada ceased . They also closed and cut up the Merchant mill and put the scrap from it ,through the #2 shop Steelmaking furnaces . Bob Newman shared I worked in this mill until it closed. Then I transferred to the rail mill at Algoma steel. Harvey Keister: I believe some of the rail equipment was sold to Bethlehem Steel Steelton Pa. Hydraulic rail straightener & Horizontal & Vertical Straightening machines. Which are still in use. Bob Newman: Harvey Keister Bethlehem still make rails? Harvey Keister: Bob Newman yes the Steelton Plant has been rolling rails since the 1800s. Bethlehem Steel went bankrupt in 2002. ISG bought the company and then sold it to Arcelar Mittal who just sold the company to Cleveland Cliffs. I worked at Steelton Pa. for 40 years in the Rail Finishing Mill. Still making T rails. At one time we made Street car rails and Girder rails. Now mostly 100rb for New York City Transit. 136re for Norfolk Southern & CXS. We did make rails for Canadian National. |

|

| Brad Place shared Wayne Jolicoeur's post Algoma Steel's Open Hearth in the 1940's |

|

| Wayne Jolicoeur posted The Open Hearth at Algoma Steel in 1952 Michael Vallecorsa shared Chris Mcdonald: This pouring process was amazing to watch but what was more amazing was to watch this process was to see it when the ladle stopper failed and the flow of molten steel couldn’t be stopped when leaving a full mold then moving to the next open mold. The molten steel went everywhere including on top of the railroad rails that the mold cars rode on. If there were any puddles of water for any reason when the molten steel would hit it there would be violent explosions. My hats off to the skill of these craneman that did this highly dangerous, highly skilled job everyday. |

|

| James Yarduk posted Algoma Steel (Sault Ste. Marie, Ont. Canada) No. 1 Continuous Casting Mill, 4 strand Bloom casting machine. (1967-1999) Photo of automatic bloom torch-cut. This machine provided blooms for rail, structural and tube round products. Blooms 9'' x 10 1/2" & 10 1/2" x 12 1/2" |

|

| James Yarduk posted Headbars exiting straightener after disconnect at Algoma Steels #1 Continuous Casting dept. (Concast) 4 strand bloom caster . This mill cast rolling product for Rails, Structurals & Tube rounds from 1967-99 in Sault Ste Marie, Ont. |

They evidently have their own iron-ore ships.

|

| Mardy Howe posted [Unfortunately, the "click the number" feature did not work for me.] |

|

| David Kaye posted CSL Tadoussac unloading what appears to be coal at Algoma Steel. 8-1-22 David Kaye shared |

|

| Group participant posted As the sun rises on Algoma steel! The international bridge to Sault Michigan in the background. [The post is anonymous because the photo is evidently from an employee.] |

Gabina Onthe Road posted four photos with the comment: "kicked down the cash for the Soo Lock Tour ...cruised up to Algoma Steel and got some pics..."

Marc ONeill: See it while you can ..they are going electric.

James Mcclure: Wow! That's awesome! L👀k like the ore yard gettin ready for winter.

|

| 1, cropped |

|

| 2 |

|

| 3 |

|

| 4 |

|

| David Kaye posted Saginaw and Michipicoten at Algoma Steel this morning, 4-1-24 James Torgeson shared Algoma Steel, Sault Ste. Marie, ON. |

|

| Jeremy Greco posted Views from the coal tower Algoma Steel Sault Ste. Marie, Ontario |

|

| R. David Megee IV commented on Jeremy's post This is another angle from a few months ago! |

I'm more interested in the ore bridge than the tugboat.

|

| Paul Ingram posted Adanac III - 1066x1600 px, 1.07 mb, 300 dpi - based on photos by Original Soo Locks Boat Tours from Great LakesTugs & Workboats: This veteran tug was built in 1913 by the Western Drydock & Shipbuilding Company of Port Arthur, Ontario as the Edward C. Whalen for the Great Lakes Dredging Company of Port Arthur. In 1938, she was sold to the Consolidated Dredging Company of Toronto, ON. She sank on the McKellar River in Port Arthur (now Thunder Bay) in October 1947 with the loss of a single life. In 1954, the Edward C. Whalen sank off Corbeil Point on Lake Superior. She was raised in 1955 and sold to A.B. McLean & Sons of Sault Ste. Marie, ON, who stripped and sank the hull in Sault Ste. Marie. She was raised again in 1958, this time for rebuilding and conversion to diesel. In 1966 she returned to service for McLean with the new name John McLean. In 1994, she was sold to Purvis Marine of Sault Ste. Marie, and renamed Adanac III the following year. Adanac III works on the St. Marys River performing various jobs for Purvis, including icebreaking, ship docking, and towing. Type: Single Screw Tugboat Year Built: 1913 Builder: Western Drydock & Shipbuilding Co., Port Arthur, ON Hull No.: 9 Engines: 1 Caterpillar D-398 Horsepower: 1,000 bhp Length: 80' 03" Breadth: 19' 03" Depth: 9' 10" Port of Registry: Sault Ste. Marie, ON |

|

| Brigitt Tessier Labby posted Making coke at steel works, Sault Ste. Marie, year 1913. [Specifically, they are pushing it out of one of the ovens.] Mark Cloutier: I was a summer student there in 1973 on the lids. Wasn't all that different. Dante's inferno on earth. Car tires nailed to the bottom of your boots and winter underwear under your work pants to fend off the searing heat, could last about 20 minutes if the recharge went ok. And then there was the coal dust and the gas fumes.... of course no mask. Sandra-May Theberge: Mark Cloutier a nasty job!! My dad worked there for years…. Died from cancer…. No surprise Michael Vallecorsa shared |

Essar Global bought Algoma Steel on June 2, but I can't find a year anywhere on the page!

Jan j2025:

|

| Mammoet posted a 0:51 video Mammoet recently helped Steel Speed Inc. to install two FTP stacks for the new electric arc furnaces at Algoma Steel Inc. The lifts were achieved using a 500t main crane and 300t tailing crane, besides two support cranes fitted with man baskets. The two stacks were over 75m tall, and weighed more than 22 tonnes. |

The tailing crane in action:

|

| @ 0:24 |

The finished stacks:

|

| @ 0:38 |

No comments:

Post a Comment