Johnstown had several steel mills. As I come across details of what was where, I'm writing notes for each mill. Most of them were owned by Bethlehem. But this one was owned by US Steel. It was special in that it was effectively the foundry and machine shop for all of the other US Steel mills.

|

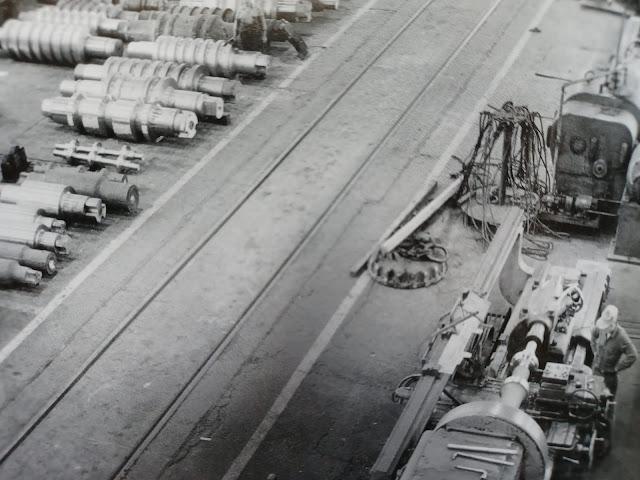

| Don Cassata posted, rotated right This is a pix of the US Steel Works in Johnstown, Pa. Probably 1950's. Ron Maxwell: It was a maintenance shop for USS , WE provided replacement parts for the other facilities because other outside contractors were too expense, so we made them here. Tony Kubic: At one time it was one of the biggest operation of its kind. From the pattern making, melting to the machining and out the door to the customer |

|

| 3D Satellite, looking Southish |

|

| Don Cassata posted A 1951 view of Johnstown Works US Steel. Robert Simanski: Put Some Years In There Now The Upper Shop, Lower Shop And Roll Shop Only Stand Everything Else Gone |

|

| Barry Messner commented on a share |

|

| Don Cassata posted This photo is marked, Pouring a steel roll in the Foundry. Johnstown Works US Steel. 1950 Robert Simanski: Yeppers Nozzleman And Helper With Mirror. R Jim Echlin: Produced thousands of rolls-both iron and steel-at Blaw Knox in East Chicago, IN prior to roll production being ceased there in the mid 1970’s. At one point in time Blaw Knox produced rolls at 5 different locations. Ultimately the company consolidated roll manufacturing at a single plant in Wheeling, West Virginia. Finally that plant was purchased by Whemco and today is just a memory. |

|

| Don Cassata posted A photo of the US Steel Foundry in Johnstown Works 1955. Johnstown Works actually had 2 foundries. #1 & #2. |

|

| Don Cassata posted Patternmakers at Johnstown Works. 1950. Michael Stilwell: Patternmakers are artists |

|

| Don Cassata posted Chippers in Johnstown's US Steel Foundry. 1950's. |

|

| Joseph Fletcher commented on a post [Heavy Duty Roll Lathe] |

|

| Don Cassata posted Today's visit to Johnstown Works US Steel takes us back to 1955. Finished Rolls. |

One of the things they built for the other US Steel mills was load specific freight cars. They also built these for other steel companies.

|

| Don Cassata posted Here's another book all the US Steel aficionados ( Is'nt that a another word for nut?) A 1950 catalog of the various Steel mill cars once made right here in Johnstown Works. Scott Gracie: Lots of steel mill specific, material handling cars.... interesting. James Torgeson: Sloss Furnaces has a couple Johnstown-built cars on display. |

|

| Don Cassata posted This is the 1st photo exploring the mill cars produced at the US Steel Johnstown Works in 1950. This 190 cubic ft. Skip Car 4 use at blast furnaces. |

|

| Don Cassata posted Today's US Steel photo from Johnstown Works features a car everyone should know. A charging box car 4 Open Hearth use. Saw many of these when I worked at Franklin Open Hearth. We actually made the charging boxes in the Boiler Shop. Peter A Mamula: The train cars carrying the boxes were very dangerous, particularly on the open Hearth floor! That is hooking them up! We had a fatality of a longer service employee days from retirement! Bill Price: Peter A Mamula We had the same thing happen at Fairless Works. The remote train operator was killed while uncoupling the charging buggies. Eric Stosius: Peter A Mamula We did a Fairless, an engineer, they all used hooks after that. Calum Learn: Were the boxes cast or fab? The ones I saw in Bethlehem and Steelton were cast but fabricated seems to be a more efficient method. Carl Jacobson: Calum Learn Remember, no welding before the 1940's. The Open Hearth shop where I worked was built in 1907. They beat the crap out of charging boxes, 24 hours a day, 7 days a week. They went from being stuck inside a 3,000 degree furnace to out in the 10 below weather in a matter of minutes. Plus they beat them up scraping slag out of the furnace doors, and in the loading process dropping crushed cubes of scrap, or scrap ingot butts into them with a magnet. Riveted boxes would have never held up. [A couple of comments provide photos of fabricated boxes.] |

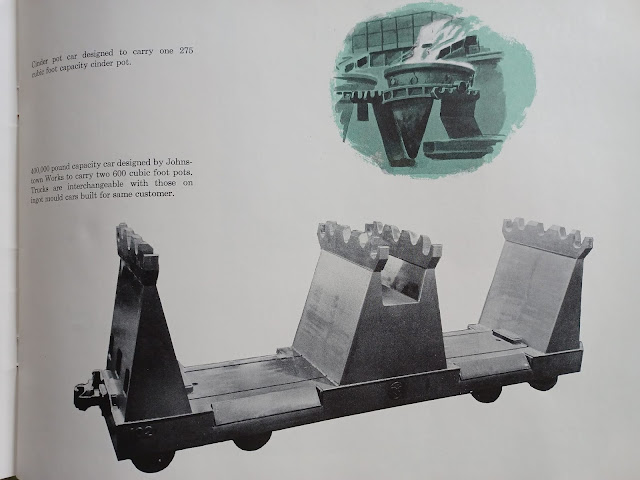

Don Cassata posted two images with the comment: "Today's US Steel Johnstown Works 1950 photos show Cinder Pot Cars made here. These r slightly different from the pots used at Bethlehem's Johnstown Plant, but same concept. My engineer buddies on the C&BL would let me take the engine up to "E" blast furnace in Lower Cambria & I would take the pots to the dump. We could have all been fired."

|

| 1 |

|

| 2 [Regular freight cars today carry 286,000 pounds. Back in the 1950s, it would have been significantly less than that.] |

|

| Don Cassata posted Today's study of Johnstown Works US Steel is a Ferromanganese Car. This car has a capacity of 140,000 lbs. These are lined with silica so the molten metal can be loaded directly from the furnace. What will they think of next? |

|

| Comments on Don's post |

|

| Comments on Don's post |

|

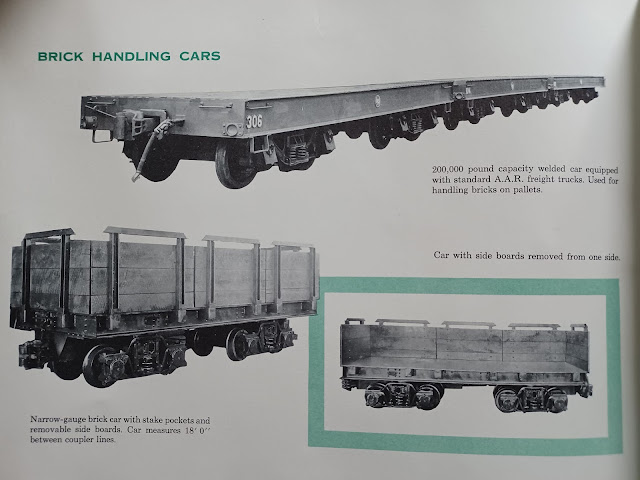

| Don Cassata posted The US Steel photo Du Jour is a Brick Car made in Johnstown Works in 1950. |

|

| Don Cassta posted |

|

| Don Cassta posted Today's topic of Johnstown Works US Steel are Coil Transfer Cars. |

|

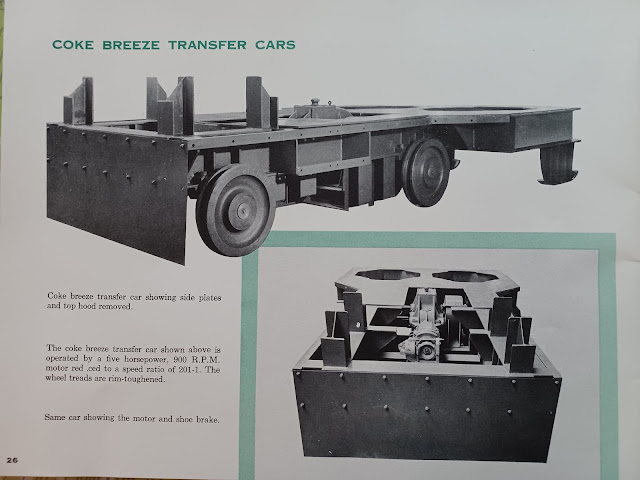

| Don Cassta posted Today's venture back to US Steel 1950 is a Coke Breeze Transfer Car. Johnstown Works did'nt have any coke production, so I suppose these were made 4 other plants. Note to Jim Torgeson: Thanks 4 catching my foulball on that last transfer car. What was I thinkin'? I knew transfer cars, by their very name r only used 2 transfer material between departments within the plant. We had various cars in Johnstown Plant we used. Anyway, good catch. Rick Rowlands: USS Johnstown Works was the central shops where a lot of the equipment used at the other plants were built. Transfer cars, ladle and slag cars, ingot cars, ladles, fabrications, castings were all made at Johnstown. |

|

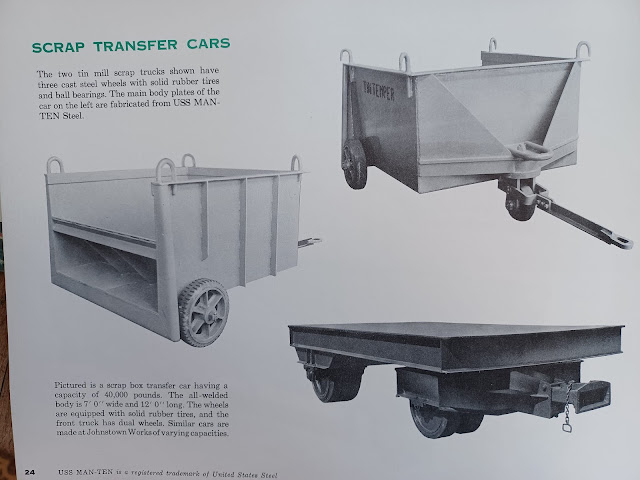

| Don Cassta posted Today's study of US Steel cars, everyone's favorite. Scrap cars. Ya know em, ya love em, ya gotta have em. |

|

| Don Cassta posted Roll Transfer Car |

|

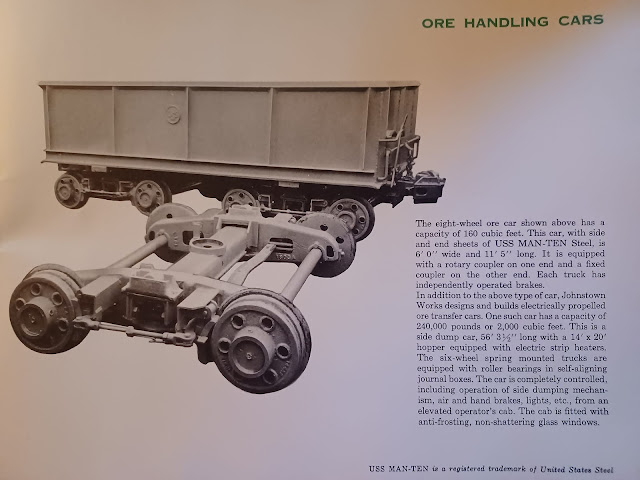

| Don Cassta posted On this very special day for US Steel, I am sending a classic from 1950. An Ore Car from Johnstown Works. I'd buy all u guys a beer to celebrate, but, I'm just a poor Bethlehem guy, so maybe J.P. left some money in his will for you. |

|

| Don Cassta posted Today's US Steel pix is a Quarry Car. Made at Johnstown Works. 1950. Does anyone know when production of these various transfer cars ceased at the Johnstown Works? |

|

| Don Cassta posted Coal transfer cars for the mining industry. 1950. Robert Franklin: There was a standard size ,but it varied by end user. Options were length,width and loaded height. |

|

| Don Cassta posted Today's study of US Steel transfer cars are Welders Buggies & a Hydro-Blast car for Foundry use. More favorites from Johnstown Works. 1950. |

|

| Don Cassta posted This 1950 Johnstown Works US Steel pix is of Tow Cars. |

|

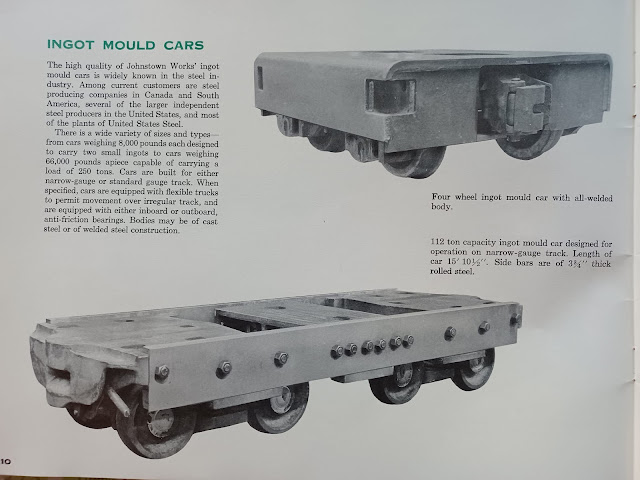

| Don Cassta posted Every Open Hearth used lines of these. [ingot mould cars] |

|

| Don Cassta posted This is another car made at Johnstown Works US Steel circa 1950. It is a Front Flush Car 4 use in Steelmaking Departments. This car features an electric motor to drive a single rear Axle. The other innovation on these cars is quite unique to Johnstown, they have rubber-baby-buggy-bumpers! Now, say that 10 times fast. |

|

| Don Cassta posted Here's another photo 4 the US Steel Boys. This pix takes us back 2 Johnstown Works in 1950, a kinder, gentler time in the steel industry. Note the double coupler. Genius! |

|

| Don Cassta posted Cinder Pot Cars in 1950. |

David Horvath posted three photos:

Ray Dietz Sr.: That’s an old slag pot.

|

| 1 |

|

| 2 David Horvath: I forget the tonnage, sheers. |

| ||

| 3 Trevor Shellhammer: Pattern and mould for open hearth charging box, in the foundry??? Asking cause I'm too young ! | David Horvath: . | Yep that's exactly it charging box |

No comments:

Post a Comment