US Steel: (Satellite)

(Update: some interior shots of the exhibits at the Heritage Discovery Center.)

(Update: some interior shots of the exhibits at the Heritage Discovery Center.)

As I figure out the details, I'm moving photos to site specific notes and turning these notes into an overview. So far, I have:

|

| Jackson-Township historical preservation posted View through Autumn leaves looking from the Inclined Plane over Downtown Johnstown in 1961. In the photo you can see the Point Stadium and a portion of the Bethlehem Steel works. Frederick Urbasik: Center of pic is the Blast Furnace in Bethlehem Lower Cambria works. Each furnace had a Coke oven plant. Phil Jadlowiec shared |

|

| epa.gov from CMU |

|

| Jackson-Township historical preservation posted Car half buried in mud in Conemaugh, looking towards the Bethlehem Steel Mills in Franklin Borough during the Johnstown Flood of 1977. (Photo from Milissa Ann) Joseph Hauzie shared The Johnstown Steel Plant during the flood of 1977, hope this picture is allowed. Tom Ray: Worked that night 11 .7 coke plant John Connelly Sr.: Tom Ray they kept us there for for days ,slept there and they brought food for us to eat daly.nasty time Mike Abernethy: I remember that 12 inches of rain in less than 24 hrs |

|

| safe_image for Johnstown: Remembering the Great Flood of 1889 |

|

| Erik Nordberg updated This week's cover photo is from the blacksmith shop at the Cambria Iron Company in Johnstown, PA. This drop hammer has been preserved and is still operated on a limited basis by Center for Metal Arts. Photo is from the Library of Congress, as collected by the Historical American Engineering Records, HAER PA-110-A https://www.loc.gov/resource/hhh.pa2288.photos/?sp=24 Information on the Center for Metal Arts: https://centerformetalarts.org/ |

|

| Don Cassata posted A 1951 booklet on Johnstown Plant Bethlehem Steel. 1951. Barry Bennett: Looks like that one is right out of the soaking pits. Poppy Jason Majo: Some people will never appreciate or understand what it’s like to stand beside 3000 deg of barely solid steel as it solidifies. I appreciate my time spent making steel that now makes our world a better place. Joseph Kaemerer: I worked 46 years at the old Inland Steel mill (1974 - 2000) as a mechanical rigger. Worked many man-hours on pit-cranes, stripper-cranes, hot metal and mill cranes. pit-cranes were the hottest . Graham Whitfield: We called them Charger Cranes, had four of them charging and emptying 36 Soaking Pits. Likewise Continuous Casting closed the Slabbing Mill in 1988. Ricky Daniel: Graham Whitfield we had one stripper crane and three pit cranes if i remember right i think we had 16 soaking pits for heating the ingots. Peter M. DeStefano: How hot do they keep the soaking pits? Are they covered? Don Cassata: Peter M. DeStefano I believe it's in the 1800 degree range. Hot enuff 2 roll, but not 2 hot 2 melt. They had sliding pit covers on them. We actually made pit covers in the Boiler Shop. |

|

| Don Cassata posted An early photo of the Kelly Converter. An early steelmaking process pioneered in Cambria Iron Co. 1860's. Randy Wilson: They were using the Bessemer process over in England before any one started it up here in the U.S. Dennis DeBruler Randy Wilson It is true that England, with their better capital, put it into production sooner. But let's be clear that Kelly invented it. Kelly started in 1847 and had his process working by 1851. Bessemer got a patent in 1855, but Kelly waited until 1857 and then soon went bankrupt. It wasn't until 1864 that a steel mill used the "air-boiling process" in the U.S. ("As early as 1847, Kelly began experimenting with what he called an air-boiling process in which he forced air into molten iron. By 1851, he apparently was beginning to produce steel in this cost saving manner. Apparently, there is some evidence that those working with Bessemer in England had learned about what Kelly was doing in Kentucky and tried to imitate the process." http://detroit1701.org/Eureka%20Iron%20Works.html) |

|

| Mike Theisler commented on Don's post |

|

| Randy Wilson commented on Don's post The Pennsylvania Steel Company. 1st steel plant built in America. Now owned by Cleveland-Cliffs Dennis DeBruler Randy Wilson In 1864, Eureka Iron Works in Wyandotte, MI, was the first to use the Kelly/Bessemer Process. Randy Wilson Dennis DeBruler I agree however, The Pennsylvania Steel Company was the first plant built specifically to make steel. They were not a converted Iron company. Dennis DeBruler Randy Wilson So Pennsylvania Steel was the first "greenfield" steel plant. That is a significant distinction. Randy Wilson Dennis DeBruler Yessir! |

|

| Don Cassata posted A view of my home away from home. Early 1970's pix of Lower Cambria Division Johnstown Plant Bethlehem Steel. Lon Shaffer: At night Franklin looked like hell with the lid off! Pat Palumbo: Those blast furnaces produced ferro manganese, which is essential in iron making. Today it is manufactured in electric arc furnaces. The US has no manganese ore. Steve Podplesky: This pic ( for those not from here) is only a fraction of what was the Johnstown Plant--BETHLEHEM STEEL CO. It goes on for miles along the Conemaugh River. Remarkably, a few of the divisions are still open under different owners. Basic steel making was finished years ago. FYI, I worked in the riggers during the 70's. |

|

| Don Cassata posted A 1957 pix of Bethlehem Steel's Lower Yard in Lower Cambria. Johnstown Plant. |

|

| Don Cassata posted An early 80's photo of "Smitty" & Larry Rhoades in Lower Cambria's historic 1864 Blacksmith Shop. Johnstown Plant Bethlehem Steel. The Steam Hammer they r working on is now owned by the Smithsonian Museum. The Blacksmith Shop is being restored & will once again be a working shop. It's a rare occasion that any of these buildings survive & r put back to their original use. Tim Soom: In the early 1980's I got a bid job on the Hammer in the Blacksmith Shop of the Homestead Works. Watching the seasoned operators with both hands moving the two different levers... made it look so simple. I tried, tried my best just did not have the co-ordination to operate it safely...had to give the bid up. |

|

| Don Cassata posted A 1905 postcard of the Cambria Steel Co. Later, Bethlehem's Lower Cambria Div. The Bessemer is on the right. |

Another photo does not provide the mills name.

.jpg) |

| Jackson-Township historical preservation posted View of the Bethlehem Steel plant in Johnstown in the 1950s. (Photo from Don Cassata via https://www.facebook.com/groups/764330635710962) |

Daniel J. Morrell, the driving force behind Cambria Iron, financed William Kelly's steelmaking experiments. Cambria Iron owned "the Gautier Steel mill that made its steel into rods, barbed wire, and agricultural implements." [ExplorePA]

|

| uncoveringpa The large steel hammer still sits inside the Cambria Iron Works. [It is owned by the Smithsonian Institute and leased to the redevelopment authority, johnstown-redevelopment] |

I learned about this company from this comment:

This shows the 1977 flood.

|

| Mike Frioio commented on his posting about Pennsy's Chief Engineer, William H Brown The Cambria Iron Works, still stands today as seen here. Apparently the city has brought in an iron working organization to teach and do demonstrations in the original forge. [These more modern buildings down by the Stone Bridge are used by JWF Defense Systems. There have also been floods in 1936 and 1977. [johnstown-redevelopment] So the Stone Bridge has passed at least a couple of tests.] |

This shows the 1977 flood.

|

| Don Cassata posted This photo was taken the morning of July 20, 1977 of the Stonycreek River in Johnstown, Pa. before it crested and destroyed our city for the 3rd time over a 100 year period. The difference between this flood & the 1889 & 1936 floods is, this one killed our economy, & essentially killed our once-thriving town. Cambria Iron & later Bethlehem Steel stayed & rebuilt the mills. 77 was the last nail in the coffin for Johnstown & Johnstown Plant. Trevor Shellhammer: Unless I'm wrong, the 77 flood caused Beth Steel to shut down the blast furnaces and change to electric arc furnaces for steelmaking, and install a big honkin' EAF, which they ran for years, still pouring ingots, including leaded free-machining steel grades?? |

"The iron industry first came to the Johnstown area in the 1840s, roughly a hundred years after it was first begun in southeastern Pennsylvania. Within a few years, the industry grew large enough that the Cambria Iron Company was formed in 1852." The buildings in the Lower Works survived the 1889 flood that wiped out much of the town (also ExplorePA) and the Blacksmith Shop dates back to 1864. Its ownership went through a succession of corporations until it was sold to Bethlehem Steel in 1923. It was shut down in 1992 and 12,000 people lost their jobs. The oldest part of the iron works was purchased in 1998 and 2003 by the Johnstown Redevelopment Authority and is being brought back to life. "At the height of the iron and steel industry in Johnstown, mills occupied 13 miles of riverfront along the rivers in and around the city, and employed thousands of workers." [uncomeringpa, johnstown-redevelopment]

|

| Chad Allan Bercosky posted Bethlehem Steel Johnstown PA.1975 Kevin Tomasic: Please credit the photographer--David Plowden. It is one of his famous photos. |

In 1853:

The erection of four coke blast furnaces, puddling furnaces and a rolling mill to make railroad rails was begun. It was here that William Kelly made experiments in 1857 with a converter into which air was blown through liquid pig iron to burn out the impurities. The old converter is still kept at the Locust Street offices of Cambria Steel. In a legal contest later, Kelly was given patent rights to his invention on the grounds of priority over the Henry Bessemer discoveries and process. In the same year John Fritz invented and put into operation the first "three high roll," a device which greatly reduced labor costs and vastly speeded up the process of rolling steel.During the mid-1870s Cambria was the largest rail producer in America." [TheVintageNews]

[History of Cambria Steel]

65 photos Another share of the same album. There are also several interior shots of the "Gautier 9" #2 Mill." A sign indicated that Bethlehem Steel stretched out along the river for 12 miles. The complex included the Steel Car Shop that made freight cars on an assembly line. I couldn't resist noting two of the photos as "a" and "b" below.

|

| a These two blast furnaces had to be from the 1800s. They appear to be cylindrical rather than the lantern shape that we are used to seeing. |

|

| b The "sand slinger" in the #2 Foundry. After the patterns had been placed in a mold, this would fill it with sand. According to some comments, it was a maintenance headache. |

|

| Josh Gruse posted Johnstown PA back in the day. William Carla Swain: Worked in the Car Shop (both Franklin, Shell plant, and the one down by the Point )from 1972 through 1982. Did some time in the Coke Plant. Prior to that I worked at USSteel. |

|

| Don Cassata posted This may be the last photo taken of Bethlehem's Electric Furnace in Johnstown shortly before the plant closed in 1992. Republic Steel then purchased it & it survived another 4 years before they folded their tent. Matt Wilks: BarTech was the initial owner that had a investment group backing. Republic bought it afterwards as BarTech had trouble after investing in new caster. The original plan was using used caster purchased in Argentina but they ended up installing new and only using parts from used one. They shutdown in 2000-2001. Mike Daniels: We tore that down in 05/06 hauled to the port of Baltimore and they shipped it to Turkey. Matthew Peters: In case you haven't realized it yet, Republic was invented to murder pension plans. |

.jpg) |

| Kevin Peterson posted Electric Furnace Meltshop. Johnstown Plant. #Bethlehem #Steel. 1991. The Plant closed in 92, but Republic Steel continued for another 4 years until closing. |

|

| Bob Ciminel posted Bethlehem Steel, Johnstown, PA, date unknown. Jeff Toth: Complete with dressy fedora! |

|

| Don Cassata posted This 1951 photo is of the Wheel Plant. Johnstown Plant Bethlehem Steel. Another piece of history was leveled recently when the former Wheel Plant was razed. Dennis DeBruler: Johnstown had a lot of Bethlehem plants. Where was this one? |

They started with their own coal mine nearby.

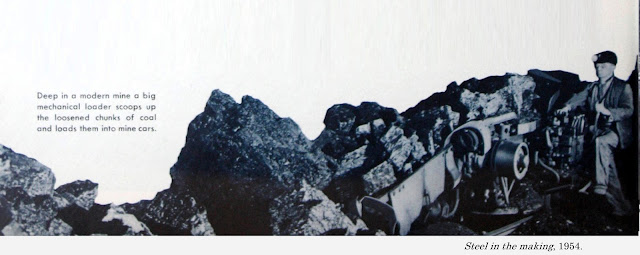

Remembering Bethlehem Mines posted two photos with the comment: "1954 Johnstown Mines."

James Torgeson shared with the comment: "A coal mine at the Bethlehem Steel Johnstown Plant."

|

| 1 |

|

| 2 |

27 photos of Bethlehem's 12" handmill, shutdown 2018

The following photos have been moved to more mill-specific notes.

No comments:

Post a Comment