|

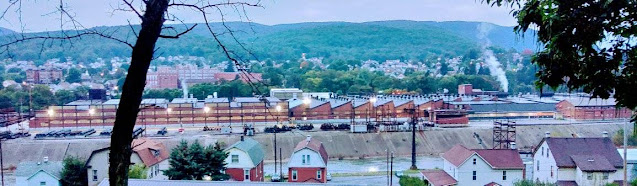

| Street View |

Ashley Energy bought the plant in 2017 and entered a 20-year agreement to "supply reliable green energy to nearly 70 buildings, hotels, sports venues and businesses in the downtown business district." The power plant started in 1904 as a coal-fired power plant. It is now a natural gas-fired cogeneration plant that feeds 17+ miles of stream distribution pipes in downtown St. Louis. [PowerEngineering]

|

| Michael Hertter posted STL. Don't know anything about. But it's a cool building. Steven Garner: Originally Ashley Plant of Union Electric Co. Robert Bjordal: I was told that it was built for the 1904 world's fair. I got to tour the plant in the late 1980s. It was supplying district heating steam at about 100 psi in the street. An amazing museum piece. There was a steam powered air compressor with brass and glass drip lubricaters all over it, wide open crosshead mechanism. flyball governor and painted like a circus calliope. The condenser cooling water pipes were riveted steel. It is now Ashley Energy, located on the Mississippi between the Stan Musial and MLK bridges. |

|

| Dennis DeBruler commented on Michael's post https://www.google.com/.../data=!3m1!1e3!4m5!3m4... |

It used to have more and bigger smokestacks.

|

| AshleyEnergy-about |

|

| stlouis-mo The building became a City Landmark in 1971. |

In 1998, the plant was providing steam to 135 customers and generating 15mw. This site was to be a new NFL riverfront stadium, but that plan was scrapped when the Rams moved to Los Angeles. [bizjournals]

|

| AshleyEnergy-benefits "Using the St. Louis district energy system means you have none of the capital costs normally associated with in-building heating systems, including boilers and other associated equipment as well as related insurance, maintenance, upgrade, and replacement costs....The system’s greater efficiency produces fewer greenhouse gas emissions than what is produced by stand-alone systems." |

This is the post that motivated researching this power plant. Note that this 2008 image caught some large smokestacks. I presume they were for coal fired boilers that have obviously been retired.

|

| safe_image for Matthew Chapman Flickr Almost 14 years ago, a coal train from the Hannibal Sub in north St. Louis City traverses the Terminal Railroad Association's High Line along the Mississippi River. In the background is the beautiful Ashley St. Power Plant. Constructed in 1902 by engineer/architect Charles Ledlic, it was the first large electrical power plant to be erected by the Union Electric Company. The building became a City Landmark in 1971. St. Louis, Missouri August 2008 |

I'm guessing Tom is referring to this "Ashley."

Tom Heintz posted two photos with the comment: "My dad began his Union Electric career at Ashley Plant when I was just a little over 4 months old. A few years ago he have me these mementos. He retired in 1993 and just celebrated 30 years of retirement 3 days ago. My sister retired in October of 2021 with almost 41 years from Osage Plant, and I'm going to leave Callaway April 1st with a little over 38 years."

|

| 1 |

|

| 2 |