While studying the Ambridge-Aliquippa Bridge I came across a comment that the town's name of Ambridge was derived from the American Bridge plant in that town.

|

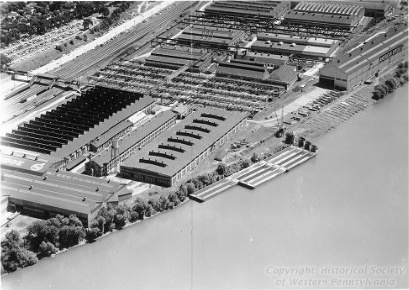

| Jackson-Township historical preservation posted Aerial view of the American Bridge plant and the community of Ambridge, Beaver County in 1945. This photo is courtesy of the U.S. War Department. The Bridge plant was in the process of building LST's (Landing Ship, Tank) for the war effort. Andrew Stewart shared |

|

| HistoricPittsburgh, MSP285.B030.F27.I01, cropped "American Bridge Company was created in April 1900, through the JP Morgan led consolidation of 28 of the largest steel fabricators and constructors in the United States. The company’s roots extend to the late 1860s, when one of the consolidated firms, Keystone Bridge Works, constructed the first steel bridge over the Mississippi River, the Eads Bridge in Saint Louis. In 1901 the company became a subsidiary of the United States Steel Corporation until 1987. During World War II, American Bridge built structural components for 43 aircraft carriers and 81 cargo ships. After the war it returned to building bridges. Some notable bridges built by the American Bridge Company are the San Francisco Bay Bridge (1936), 25th of April Bridge in Lisbon, Portugal (1966), and the Sunshine Skywalk Bridge in Florida (1986). American Bridge Company has also participated in the construction of many famous buildings including the Sears Tower, the Empire State Building, and the Chrysler Building. The facility pictured here was located in Ambridge, Pennsylvania. American Bridge Company is currently privately owned." American Bridge built this plant in 1903 and closed many of the 28 plants that were absorbed in 1900. Bob Ciminel posted Michael Maitland: This plant appeared to be so huge. Not familiar with what was done here - help? Presume cutting, welding and designing bridges that would be shipped to be assembled? Did they roll steel here, or get it from the main US Steel plants. James Torgeson: Michael Maitland Yes, it fabricated steel structures of all types using steel plate, beams, wire, pipe etc. from various USS plants. and sometimes outside manufacturers. It also built barges, LSTs and other vessels. It was the largest fabricating plant in the world, and could ship by rail, road or water. Ambridge was also the home of the AB divisional offices and its engineering and design staff. William Scott: We serviced Motorola's first remote control locomotive, at that plant, around 1970. |

|

| Jackson-Township historical preservation posted Aerial view of the American Bridge plant and the community of Ambridge located along the Ohio River in Beaver County in 1945. This photo is courtesy of the U.S. War Department. The Bridge plant was in the process of building LST's (Landing Ship, Tank) for the war effort. |

Ambridge was founded as a "smokeless" town. Only companies that fabricated steel would be allowed to build in the town. But J&L building a big integrated mill upwind in Aliquippa smothered the claim of "smokeless." [PaulHertneky]

|

| David Holoweiko posted Welding la LST hull 1945 American Bridge in Ambridge PA .. LST or Landing ship, tank (LST), were naval ship specially designed to transport and deploy troops, vehicles, and supplies onto foreign shores for the conduct of offensive military operations. They were capable of pulling up directly to the beach and had large doors that opened to permit tanks trucks and troops to land on the beach . Bob Mcendoo: LST long slow target. James Ujevich: Bob Mcendoo yeah. We said large though. USN. |

|

| Eric Krithinithis posted American Bridge, Ambridge Pa . Carl Jacobson: Looks like the barge fabrication shop. |

|

| David Holoweiko posted Although not a steel mill so to speak more of a fabricator . This was the immense American Bridge Plant in Ambridge PA the town that was named after the plant. Have some great real photos will post after the holidays. |

|

| Bob Ciminel posted American Bridge, Ambridge, PA, date unknown. [A comment suggests 1922.] |

|

| Iron Age Article via Historic Bridges, p5 [This also has photos of the 5-ton riveter gantry and the "Track Jib Crane."] |

|

| OldEconomyVillage American Bridge bought the 2,500 acres owned by the Harmony Society in 1903. This gave them plenty of land along the Ohio River on which they built a company town as well as a big and efficient plant to replace many of the plants that it bought in 1900. "Ambridge prospered and by 1930 had a population of over 20,000 people. Unlike many company-built towns, the workers of Ambridge became property owners quickly." |

|

| Eric Krithinithis posted Sippel Steel ,Old American bridge plant Ambridge Pa. Douglas Warner: Used to work at their old plant in Gary Indiana. Neat place lots of history. |

Ambridge-Woodlawn was another name for the Ambridge-Aliquippa Bridge.

|

| 1953 Ambridge Quadrangle @ 1:24,000 |

In addition to fabricating bridges and skyscrapers, it fabricated hulls for boats.

|

| WaterwaysJournal "In 1927, the American Bridge Company at Ambridge, Pa., constructed a steel hull measuring 169.8 feet in length by 38.9 feet in width and having a depth of 6.5 feet for the Carnegie Steel Company, which had contracted for the new towboat in 1924." |

Eric Krithinithis posted ten photos with the comment: "American Bridge , Ambridge Pa. 1943."

[Since 1943 is during WII, they are building LSTs (Landing Ship Tank) like the ones built in Seneca, IL except that they already had the buildings, employees, etc.]

Hunter Jones: Really nice pictures of Ambridge. Mom was a welder there during the war. She always use to talk about wondering if her welds held.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| TimesOnline Ambridge and American Bridge C. plant is in the foreground. [B. F. Jones Memorial Library in Aliquippa] |

I hope they build their bridges better than they build their web site. When I clicked the "View Project" link, I got a 404 response! They now have four locations, but the only one that is not just an office building is Tampa Bay. The history page is of interest.

|

| AmericanBridge |

Keyhole Bar & Grill posted seven photos with the comment: "Ironworkers can tend to be a little high maintenance sometimes. Before the first section of tower was set on July 5th, 1955, they were assembled on the ground in Ambridge Pennsylvania to make sure they fit together properly. They were then dismantled and shipped to St. Ignace by rail, loaded up on a barge and taken to where they have stood for the last 66 plus years. Each section weighed 19 1/2 ton. They assembled 50 feet a week until they reached 552 feet above the water. The last photo is the first section of tower being set on July 5th, 1955. Each tower weighs approximately 3250 tons. Quite the feat. Enjoy the Day!"

James Torgeson shared

Some scenes of the American Bridge Division of USS building Mighty Mac! Note the photo of one of the towers being assembled on the ground at the giant American Bridge home plant in Ambridge. (By the way, the Keyhole Bar in Mac City has great food!)

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| Kevin Schlott posted Progress and Launching photographs of the USS LST-262, American Bridge Co., Ambridge Shipyard Launched – February 13, 1943 [At least this location had plenty of steel handling infrastructure. The Prairie Shipyards such as the one in Seneca, IL, had to create everything from scratch to build LSTs.] Carl Jacobson: In the early 1980’s American Bridge was still building barges in that building. |

Andrew Stewart: The LST's were built in the part of the plant where Hussey Copper is today.

Bill Franz: As did Dravo on Neville Island.

%20Philadelphia%20Industrial%20&%20Commercial%20Heritage%20_%20%23DelawareRiver%20%23Constructi.png)

The website photos may be a bit deceiving - the Coraopolis location contains two large buildings that were a fab shop and paint building until about 10 years ago. Coraopolis also has a large yard of bridge building equipment, some of which dates to the USS years (falsework, derricks). One of the stiffleg derricks is erected on a river bulkhead for loading/unloading barges.

ReplyDelete