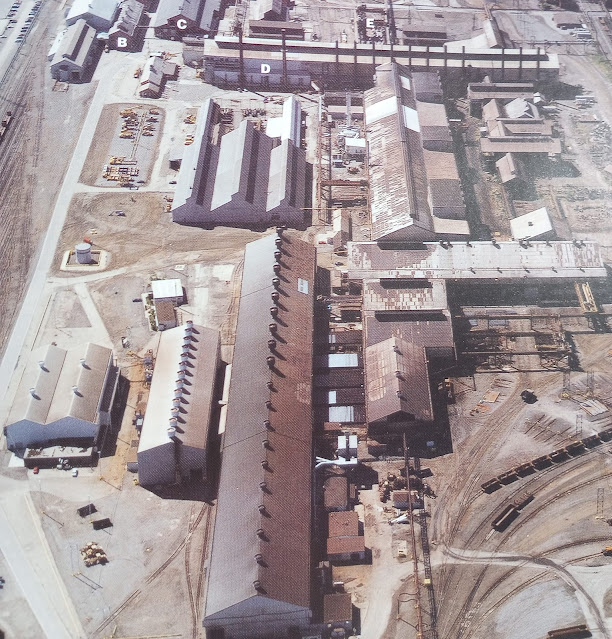

Drone photo by Bubba Dubs: Republic Steel's Mexican owner, Grupo Simec reports that Lorain No.4 BF has a book value of zero, but is still held in reserve with confidence that it will be restarted in the future. Wishful thinking?

Republic Steel Inc.

Republic Steel (formerly Republic Engineered Steels), owned by Mexican steelmaker Group Simec Guadalajara, incorporates the remnants of the steelmaking and SBQ bar rolling facilities of the former LTV Steel, Bethlehem Steel and U.S. Steel integrated giants.

The facilities are located at Canton and Massillon in Ohio (originally Republic Steel), Lorain in Ohio (originally U.S. Steel) and Lackawanna in New York (formerly Bethlehem Steel). The steelmaking remnants of the Bethlehem Johnstown PA plant were also merged into the Republic Engineered bar assets in 1999 but shut down by 2000.

The convoluted history of these remnant plants over the past three decades has been difficult to document, but here is my history and current status of these plants.

THREE IMPORTANT QUESTION – HELP REQUESTED

1) Can anyone help with details of the continuous caster installed by Bar Technologies in 1996 or 1997 at the former Bethlehem Johnstown plant?

2) Can anyone confirm what year USS/KOBE installed a tank vacuum degasser at the Lorain melt shop? I think possibly in the late-1990s.

3) Can anyone help clarify this apparent contradiction from two key sources: the 2022 AIST survey of North American EAFs lists Canton as having one 220 net ton upgraded EAF and also one old 100 net ton furnace (idle since 2020). But the Grupo Simec 2022 Annual Report says Canton has 2 x 200 ton EAFs.

Republic Steel Central Alloy District, Canton Works, Canton OH

Established BF 1916, OH 1904, EAF 1914, mills 1904.

BF closed late 1970s, OHs closed late 1960s – all obsolete, replaced by expanded EAF alloy and stainless steelmaking (9 EAFs - 1.5 Mtpa).

Established 1904 by United Steel Company, renamed United Alloy Steel Corp. in 1916, merged into Central Alloy Steel Company 1926 then merged into Republic Steel in 1930. Republic Steel in 1984 merged with Jones and Laughlin Steel to form LTV Steel. Major expansion by 1920 included two OH shops, first 3 EAFs, primary mills and five bar mills. WWII brought huge expansion of EAF steelmaking (11 x 65/70t) to produce alloy steel for tank armour. Major modernization began in 1968 with addition of 4 x 200t EAFs, followed by a bloom caster. Today, just one upgraded 220t EAF produces 80% of the capacity of the original four furnaces.

1960 lineup: 1 small BF (0.266 Mtpa), 6 OH x 170/190t (0.560 Mtpa), 10 EAFs (0.485 Mtpa), 2 bloom mills/3 bar mills, 21 sheet mills

2022 lineup : 1 x 220t EAF, 110 MVA upgraded 1995 – 0.900 Mtpa, and 1 x 110t EAF, 20MVA 1951 [idle since 2020] – 0.300 Mtpa, 4-strand bloom caster (upgraded 1995) 0.860 Mtpa, 5-strand billet/bloom caster (2005) 0.680 Mtpa coupled with 8-stand Flex Cast-Roll mill for billets and square bars. 12” bar mill closed 2002 and primary mill probably closed about 2005.)

Currently still operating as the sole steelmaking, bloom & flex casting/billet mill facilities feeding the Republic bar mills at Lackawanna (13” mill operating) and Lorain (20” billet/bar mill & 9”/10” mill – idled since 2015)

Republic Steel Central Alloy District, Massillon Works, Massillon OH

Established BF 1926, OH 1915, mills 1915. BF closed 1965, OHs closed early 1960s – primary operations then obsolete. Billet mill and one bar mill continued operations until 2002. Massillon cold bar finishing continues in operation by Republic Steel.

Established 1915 by Central Steel Co., merged into Central Alloy Steel Corp. in 1926, and then into Republic Steel in 1930. Republic Steel in 1984 merged with Jones and Laughlin Steel to form LTV Steel.

Massillon 1960 lineup: 1 small BF (0.266 Mtpa), 9 OH x 115/225t (0.680 Mtpa), bloom/billet/2 bar mills, 9 rev. cold strip mills.

Massillon 2022 lineup: cold finished bar facilities 0.038 Mtpa, operated by Republic Steel.

Bethelehem Steel Bar Division, Lackawanna plant, Lackawanna NY

Established BF 1903, Bessemer 1903, OH 1904, mills 1903. Established 1903 by Lackawanna Steel Company, merged into Bethlehem Steel in 1922.

Integrated BF/BOF steel operations closed 1983. The Lackawanna 13” SBQ bar mill built in 1976 continued to be operated by Bethlehem Bar, Rod and Wire Division until 1993. In 1994 Veritas Capital Inc acquired the 13” mill for $13 million and operated it as part of Bar Technologies Inc. This was merged into Republic Engineered Steels in 1998.

Lackawanna 1960 lineup: 2 small & 5 medium BFs (3.8 Mtpa), 3 OH shops (total 35 furnaces 150/300t, 6.0 Mtpa), 3 bloom mills/billet/rail/heavy & medium structural/4 bar/79” hot strip mill/2 cold reduction/6 cold finishing mills.

Lackawanna 2022 lineup: 13” SBQ bar mill, 0.653 Mtpa, built 1976, recently upgraded with a 5-stand sizing mill, operated by Republic Steel.

U.S. Steel Lorain Works, Lorain OH

Established BF 1898, Bessemer 1895, OH 1909, mills 1895.

BF/BOF idled 2008 (but No.4 BF still in reserve), BOF replaced 2013 by EAF steelmaking, The new EAF and bar mills idled since 2015 but still in reserve.

Lorain plant history: Lorain plant was established 1895 by Johnson Steel and Rail Company as a Bessemer steel plant producing tram rails. BF ironmaking followed in 1898. In 1899 Lorain was acquired by Judge Gary’s Federal Steel Company, which was a foundation component in the creation of U. S. Steel Corporation in 1901. With the introduction of pipe mills in 1904, the plant was renamed National Tube Company. Open hearth steelmaking was introduced in 1909 and over the next four decades Lorain grew to become the world’s largest pipe producer. In 1949 Lorain installed USA’s last high capacity Bessemer steel shop, which was replaced in 1971 by BOF steelmaking, using much of the Bessemer shop infrastructure. In 1969/70 two high capacity 10” and 12” bar mills were added to produce automotive SBQ grades. Bloom casting and ladle steelmaking was added in the mid-1980s. In 1989, USX and Kobe Steel Company formed a 50/50 venture, USS/KOBE Steel Company, to acquire and operate Lorain works, excluding the pipe mills (which continued to be operated by USS). In 1995 a second caster was added to provide 100% continuous casting. A tank vacuum degasser was also added, possibly sometime during the 1990s (but I am still trying to pin down what year this was commissioned).

Lorain 1960 lineup: 3 small and 2 medium BFs (2.2 Mtpa), 12 OHs x 185t (1.8 Mtpa), 3 Bessemer x 30t (0.9 Mtpa), 46”/40” 2-stand bloom mill (1949), 30”/21” cont. billet mill (1949), 2 heavy mills for rounds for seamless tube feed, 2 skelp mills for welded tube feed.

Lorain 2022 lineup: all indefinitely idled in reserve. BF No. 4 (3500 tpd) idle since 2008 but still held in reserve with possibility for recommissioning if the market improves (2018 study investigated recommissioning the BF to market pig iron to flat product mini mills, but the project did not go ahead). A 150t EAF (1.2 Mtpa) built 2013 but idle since 2015. Ladle refining and tank vacuum degassing, 6-strand bloom caster (1.0 Mtpa, built 1983) and 5-strand bloom caster (1.2 Mtpa, built 1995), billet/heavy bar mill (1.2 Mtpa, built 1949), 12” SBQ bar mill (0.500 Mtpa, built 1970) and 9”/10” SBQ bar mill (0.420 Mtpa, built 1969, upgraded 1991). Grupo Simec said in its 2022 annual report that the 9”/10” mill is being prepared for recommissioning to produce cold-heading quality and SBQ bars as soon as market improves. The annual report also stated that the No.4 BF was written down to zero book value in 2015. But it is still held in idle status, with intention to recommission when the market improves. A coke inventory is still valued at $1.3 million.

LTV Bar Division and USS/Kobe post-integrated steel operations: in 1989, an ESOP called Republic Engineered Steels (RES) purchased LTV Steel’s bar division. In 1998 RES merged with Bar Technologies (then operating the residue of the former Bethlehem Steel Johnstown plant and the former Lackawanna bar mill) to form Republic Technologies International (RTI). In 1999 RTI acquired the integrated steel bar mill business of USS/KOBE Steel in Lorain, OH. RTI declared Chapter 11 bankruptcy in 2001 and was purchased in 2002 by Republic Engineered Products Holdings LLC (REP). The total acquisition cost was $410 million. REP chose not to acquire the idled meltshop and caster at Johnstown, but did acquire the Canton and Lorain meltshops and casters (0.9 and 1.5 Mtpa). The Lorain plant still operated BF/BOP route feeding a five-strand bloom caster and six-strand bloom caster. REP acquired the Canton billet mill, Lackawanna bar mill (0.588 Mtpa), only two of the three Lorain bar mills (0.432 Mtpa), but rejected the remaining Massillon and Chicago bar mills (0.9 Mtpa). RTI closed the Massillon bar mill, the Canton 12” bar mill and the Lorain 12” bar mill all in 2002.

REP acquired bar cold finishing facilities at Massillon (0.1 Mtpa) and Gary (0.08 Mtpa), rejecting another six bar cold finishing plants (0.1 Mtpa). In 2005 Republic Engineered Products Inc. was acquired by Mexican steelmaker Grupo Simec Guadalajara. In 2011 the name of the US bar subsidiary was changed to Republic Steel (turning the clock back almost four decades).

In 2013 Republic Steel commissioned a 150t EAF (1.0 Mtpa) at Lorain, but this and the rest of the Lorain plant was idled in 1915 and has not been operated since. It is however still held in reserve for when the market justifies recommissioning.

Related background, no longer involving Republic Steel.

Bethlehem Steel, Cambria Works, Johnstown PA

Established BF 1853, Bessemer 1871, OH 1879, mills 1853.

Established 1852 by Cambria Iron Co. reorganised 1862 as Cambria Steel Co. By 1880 it was the largest steel plant in the USA. Merged into Midvale Steel and Ordinance Co. in 1916, then acquired by Bethlehem Steel in 1923. There was a burst of new and modernised mill investments from 1924 to 1926, then over the next half century Johnstown plant received only sporadic modernisation investments and limited expansion compared to other Bethlehem integrated mills. By the 1960s Johnstown was faced with outmoded technology, vulnerable bar and rod product range, and poor location for both raw materials and market access. Bethlehem Steel’s strategic planning response showed surprising lack of direction. In 1969 construction began on a continuous caster, but after millions had been invested in site work and foundations, the project was cancelled. In 1973 a project was announced to build an EAF shop to replace the obsolete BFs and OHs, reducing steel capacity from 2.3 to 1.0 Mtpa. By 1974 this was cancelled. In 1975 work began on a BOF shop, requiring continued operation of the BFs. Completion was targeted for 1978, but in 1977 a major flood once again seriously damaged the Johnstown plant. The BOF project was abandoned and a new plan to install EAFs was adopted, this time reducing capacity from 1.8 to 1.2 Mtpa. Once again, the new steel shop would have no continuous casting!

Johnstown 1960 lineup: 4 small & 2 medium BFs (2.0 Mtpa), 20 OH x 170t (2.4 Mtpa), bloom/2 billet/9 bar/rod/wire/2 plate mills

Johnstown 2022 lineup: two or three of the original Gautier plant mills (9” and 14” bar mills both built 1926) are still operated by Gautier Steel. The 12” mill (built 1893) might have been closed. The original Johnstown wire mill is now operated by Liberty Wire Johnstown.

Johnstown post-integrated steel operations: Closed BF/OH 1981, replaced by 2 x 185t EAFs, which Bethlehem continued to operate (without continuous casting) until 1992. The EAFs and remaining mills were then closed and offered for sale. Veritas Capital Inc. purchased the Johnstown plant in late-1994 for $25 million, planning to operate the EAF shop and add a caster, to produce 0.7 Mtpa of billets to feed the Lackawanna 13” bar mill, also purchased for $13 milllion by Veritas Capital. BRW Steel Corp. was set up by Veritas to be the operating company, but the name was later changed to Bar Technologies Inc. Limited production at Johnstown resumed in 1996 and a caster was commissioned in late 1996 or early 1997, but the operation suffered heavy losses. The Johnstown primary plant and Lackawanna bar mill were merged by Veritas and associated Blackstone Group into Republic Technologies International in 1999. The Johnstown plant was permanently closed incurring a $55 million write off in 1999/2000.

The three remaining Johnstown Gautier plant specialty bar mills (14”, 12” and 9”) were acquired by J-Pitt Steel Inc. in 1993. J-Pitt filed for bankruptcy in 1997 and ownership changed to Gautier Steel Ltd. in 1998. The three bar mills are still operated by Gautier today. In 2015, associated firm Gautier Specialty Metals added a 58” 4-high plate mill for alloy, tool, stainless steels and titanium armour plate. This plate mill was re-engineered from a decommissioned plate mill from Gadsden AL., with the future option of widening to 110” width. The Gautier bar and plate mills are operated in the original Gautier plant mill buildings constructed in 1892. The three bar mills were originally built in 1893, 1926 and 1926, so are now 96 to 129 years old.

The Johnstown wire mill was acquired in 1992 by Johnstown Wire Technologies, which in turn was acquired in 2019 by the Sanjeev Gupta’s international Liberty Steel Group, renaming it Liberty Wire Johnstown.

[Some comments speculate that Grupo Simec bought it to shut it down to remove competition.]

%20Steel%20Mill%20Pictorial%20_%20Facebook.png)