The Weir Brothers bought the Peter Tarr Furnace and then expanded to form the Weirton Steel Mills. [James Tarr]

|

| Nick Markowitz Jr. shared Vicki Thomas' post The City of Weirton with the open hearth of Weirton Steel Mills in the background. Jessie Herrera: My mother's first teaching job was in Weirton in late 30s, probably 38. She said that everyday when she went into her classroom she had to clean the black soot off of the children's desks. The soot made its way in even thru the closed windows. I think she taught at Weirton High. Scott Gracie posted The primary view is Weirton Steel's Open Hearth in the center background with the Blooming Mill immediately behind to the left and the Blast Furnaces to the back right.....circa 1940 or just after WWII. The homes in the foreground are mostly gone along with all of the pictured Steelworks departments. This is looking west/northwest from Weir Avenue with the lower Pennsylvania Ave / Main St/ County Rd intersection in the center.....the Mill Administration Building in the center left still stands. |

|

| John Slowikowski posted Would have liked to have seen exactly this sight in person. Richard M Allen: Weirton at one time was the largest fully integrated steel mill. Kenneth Treharn: I think I see 2 blast furnaces and 11 open Hearth stacks. I guess the blast furnaces could support 8, maybe 9 Open Hearth Furnaces. It depends on the size of the blast furnaces. A nice things about Open Hearths is they could adjust how much Hot Metal. What we called an "ore" charge used a higher percentage of Hot Metal, this was a faster heat. The "scrap" charges use less percentage of Hot Metal, we'd charge a percentage of broken moulds/stools for there iron content. Doug Cheek: Kenneth Treharn when I worked in #4 open hearth at sparrows point they used 5 furnaces out of 7 when the 6th one fire up they would shut one down for rebrick. Buck Henry: This pic is from the open hearth days. Late 1960’s and earlier. BOF and EAF are the standard now. Much much less smoke. |

|

| Scott Gracie posted This is Weirton Steel Division Of National Steel....circa 1957 about 14 years before the EPA. The #2 Warehouse (central right) had been previously used as a shell plant, during WWII......this would be razed for the BOP, that would be completed around 1967. The areas marked "Blooming Mill" and "Structural Mill" are reversed. The point of view is looking north/northwest from Powerhouse Hill or S 11th St, a back street, that goes from Weir Ave, downtown up to Weirton Heights. |

|

| History of the Ohio Valley posted A plane flies over Weirton Steel Corporation’s tin mill and blast furnaces, in Weirton- ca. 1940s. |

|

| Dan Tassey posted The good old days. Mike Allen shared [The tin plate line still runs with coils shipped in from Cleveland.] |

|

| Mendez Martin uploaded on Mike's share as part of a discussion of the continuous annealing line. These were evidently an early 1960s technology. |

|

| Robert Shockley posted It's all gone now. |

|

| Weirton Steel Hometown posted WSX played an important role ending the War John Slowikowski shared |

|

| Vince Trupiano posted Bubba Dubs: The lack of the American mills to adapt new technology, especially continuous casting and the BOF put the writing on the wall 20-30 years before the wolf finally came. It’s interesting that Weirton adapted those modern processes but failed to weather the storm. Weirton’s major issue was it’s raw material costs, especially the transportation costs. Once that’s was coupled with the mismanagement, it’s was over. Rodney Temple  Read This I did about 10 years ago. Its the real reason written by a former board member. https://www.amazon.com/Board-Betrayal.../dp/0923568514 |

|

| Josephine Lily Brown posted Weirton Steel: This popped up on Pinterest and I almost fell off my chair! Matt Sell’s beautiful shot of Weirton. Well done Matt Sell!!! |

|

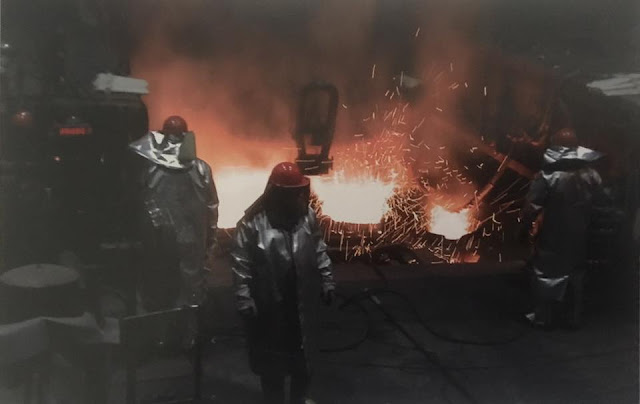

| William Livingston posted Weirton Steel continuous caster pouring platform 1973. |

|

| Donald Hall commented on William's post Picture is prior to slide gate ladles from Mitsubishi ! This picture is after ! |

|

| Donald Hall commented on William's post |

|

| Scott Gracie posted Weirton Steel (National Steel) in Weirton, WV......circa 1957. The building with the open door is the old Structural Mill Warehouse and Structural Finishing Mill. On this day, it appears there was a large tour being conducted with P&W buses for guests parked adjacent to the building. Also present is a Pennsylvania RR passenger train, likely in its last days of use in the area. Out of the picture to the left was a depot known as Crawford Crossing, that Weirton Steel bought to use for its safety equipment store. The Structural Mill ceased operations around 1978....the Blooming Mill in 1992 and all hot operations in 2005. Everything in this photo has since been leveled and is being developed for other industrial use. Weirton's Tin Mill out of view to the upper left is being operated today by Cleveland Cliffs. |

Charlie Whipp posted two photos with the comment: "One of the things that I enjoy when looking through images taken decades ago is to go to Google and look at the street level views to see what has changed over the years. Weirton, WV was about as much of a steel town as can be imagined so, when Weirton Steel went under, the effect was drastic on the local economy. This effect is very evident in this old view from March 28, 1987, at Main and Avenue A Streets. The huge, sprawling mill complex was at the center of town at Weirton and dominated the view as well as the regional economy. Over the years, the removal of the mill and many of the businesses that surrounded it made this view almost unrecognizable to me, so much so that I had to triple check myself when I looked up the location. I'll post the link to a recent Google street view in the comments."

Charlie Whipp: https://goo.gl/maps/QMwEC3cvzXZTqW7FA

Bill Kloss shared

Carl Lipski: Once the largest employer in West Virginia. Now it’s Walmart. [Does Walmart have warehousing operations in WV?]

|

| 1 |

|

| 2 |

|

| Perry Wilson posted Weirton Steel, Weirton, WV. circa 1968. The mill weaved its way in and around town for miles past homes, churches and down Main Street. You could walk out of your mill gate and sit down for a beer twenty feet across the street. Weirton Steel created wealth for the city and residents of Weirton and the city still exists because of that. This photo was the northernmost part of the main mill. Probably taken from County Road looking south. |

Austin Angus posted four photos with the comment: "Few more Weirton Steel."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

Gavin Frank posted three photos with the comment: "Bessemer converters from Weirton steel."

|

| 1 |

|

| 2 |

|

| 3 |

|

| Jeff Picka posted Weirton Steel as seen from Main St at Virginia Ave in Weirton WV on Dec 23, 2013. Joe Valles: When I got hired in 78 there was over 14000..... Karen N Shawn Dulaney: Working there now, about 850 employees. |

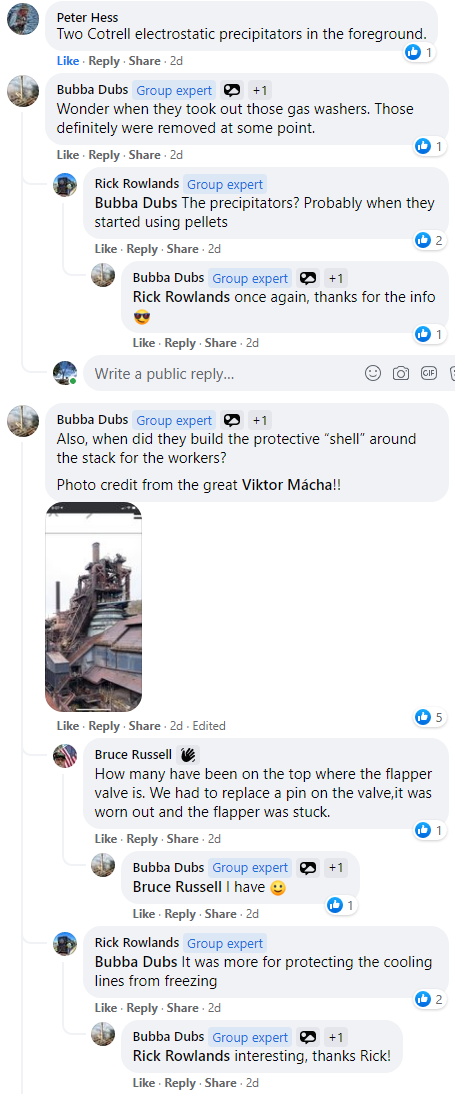

Bubba Dubs posted two photos with the comment: "Weirton blast furnaces 1-3 (right to left) 8-16-14"

|

| 1 |

|

| 2 |

.jpg) |

| David Bischof posted 3 of the 4 Blast Furnaces at Weirton Steel, they were once hot and glowing and producing iron for the BOP. This photo was taken in 2016 when they were cold and abandoned. They are now gone forever. Jerry Goodwin: Nice picture David Bischof! This shows, left to right, #1-#2-#3 furnaces |

|

| Jeff Picka posted Remains of northernmost of the four blast furnaces at Weirton Steel in December 2013. This shot was taken from Main at Ave B. Robert Shockley: The Blast Furnaces at Weirton Steel produced on average 6800 tons per day, while I was there in the mid sixties. Chris Balch: Form energy is building a battery plant their right now. Scott Gracie: Those were gone within a few years after this picture. At Weirton, if I recall correctly, their furnaces were a bit smaller, than most.....I don't recall the size capacity. They most always had three running together, having a fresh reline of a forth ready to go, rotating a fresh one in, then rebuilding a fourth, so on & so on. That would be #4 , furthest north, in Jeff's picture. |

|

| Charlie Whipp posted Making steel at the Weirton Steel Company's mill at Weirton, W.V. The mill was located in the valley with the town built around it. March 1987 James Torgeson shared Charlie Whipp shared a similar view. |

|

| John Slowikowski commented on James share Know that spot |

|

| John Slowikowski shared |

|

| John Slowikowski commented on his share All that is left of #1 furnace |

Since the #1 furnace would be their oldest, I'm surprised there is that much left. But I could not find these three stoves and smokestack on Google Maps.

|

| 3D Satellite |

|

| Raymond Boothe posted Weirton Steel Corporation: This is a view of the uptakes and downcomer of blast furnace No. 1 (Dr. Raymond Boothe photograph). |

|

| Raymond Boothe posted Weirton Steel Corporation-Weirton, West Virginia: Detailed view of the top works of blast furnace No. 4 (Dr. Raymond Boothe Photograph). |

|

| Michael Jones posted Weirton Steel…i forget which furnace this was, taken around 2012. Larry Mitchell: It looks like #1 BF looks like there are two tap holes. |

|

| Jerry Goodwin commented on Larry's comment Larry Mitchell here's a shot of #1 cast house. Michael Jone's pic is #2 furnace. |

|

| Steve Heselden posted Weirton, West Virginia Steel Mill Blast Furnace in 2012 John-Paul Kuzma: That was #1 Blast Furnace we ran at 130,000 wind!!! We were number three in the country with how much iron we produced!! Richard Blankenship: The drill, which tapped the furnace…. And clay plugger, when furnace blew empty…… Denny Paderewski: One hell of a WATER JACKET!!! Ken Rogers: Sure wish I knew what I was looking at but even at that its fascinating as hell. -some dumb bodyshop guy in nowhere Illinois 🤣 Chuck Varner: It's one of Weirton Steels Blast Furnaces. When the mill shut down No.1 and No. 4 was running. Can't tell which one this is!!! The device in front is called a drill ore commonly known as the " Tapping Jack!" It drilled into the front of the furnace and allowed the iron and slag run out of the furnace. Slag was put into slag pots and iron into iron bottles. The full slag pots would be unloaded and brought back for reuse. Iron bottles were sent to the B.O.P. where iron was mixed with other materials to make steel" When it was empty the other large device called the mud gun would inject a mud type material which would stop the flow of materials. Then more materials. (Iron ore pellets. Scrap metal. Limestone and metallurgical coke that heated all the materials to their melting points inside the furnace. Then it would be unloaded into large bins that would be weighed in the stock house and unloaded into what was called skip cars which would take the material to the top of the furnace and dumped until it was melted into whatever grade iron was needed for the order. When one skip was on top of the furnace the other skip was at the bottom in the stock house hoisted buy large steel cables. The material that filled the bins was unloaded by the Hi-line crew. From railroad cars on the coke side of the Hi-line by a remote control Locomotive which was operated by the senior wrenchman. A remote control box It was about the size of a small igloo lunchbox. Operating a full size Locomotive and usually about 20 full size railroad cars fully loaded. It was amazing how far modern technology had taken us. I was one of the 4 senior wrenchman / Gangleaders in Weirton Steel on the coke side. On the Iron side they would send up full cars from the yard by the Weirton Steel Railroad. Full of iron ore pellets to be unloaded by another Locomotive and crew. Then they cut jobs and combined the two jobs together so one crew would unload both types of material. And that's how Iron was made in a nutshell. |

|

| Raymond Boothe posted View of the Weirton blast furnace highline (Dr. Raymond Boothe photograph) |

|

| Raymond Boothe posted Charging one of Weirton Steel Corporations' 600 ton open hearth furnaces. One of the largest in North America (Dr. Raymond Boothe collection). |

|

| The Beauty of Steel project posted The former open-hearth steel shop at Weirton Steel, WV. An empty field now. Photographer unknown. |

|

| Chris Litherland Photography posted Here's a photo from a few years ago of the abandoned powerhouse at Weirton Steel, in WV. Weirton Steel is now being torn down completely. Most of the steel mill was abandoned in the early 2000's, although parts were still used up into a few years ago. In 1905 Ernest Tener Weir, a Pittsburgh, Pennsylvania-area steel employee, enlisted a partner to buy the Phillips Sheet and Tin Plate Company, an ailing steel company in Clarksburg, West Virginia. The plant flourished under Weir's stewardship, and within four years he was looking for a new site to accommodate expansion. The site would have to have access to coal mines, water sources, river and rail transportation, and centers of industry. Weir found his ideal industrial site in the northern finger of West Virginia that separates Ohio and Pennsylvania, about 39 miles from Pittsburgh. In 1909 Weir began building on 105 acres he purchased near the hamlet of Hollidays Cove. By the end of the year, Weir had ten steel mills operating, and mill workers had started to come in from as far away as Greece and Italy. The boom continued throughout the decade. By 1920, more than 15,000 people lived in the area. As growth continued, Hollidays Cove expanded rapidly and new communities like Weirton, Weirton Heights, and Marland Heights sprang up nearby. In 1947 all these villages would be incorporated into the city of Weirton. Chris Litherland Photography Prints are available here. http://chrislitherlandphotography.zenfolio.com/.../e93ab50a9 Chris Litherland Photography Pretty amazing documentary/education film about Weirton Steel in 1969. https://www.youtube.com/watch?v=B9okBTLJVKc Randy Cooke: Not sure of the purpose but those are motor generators that ac 3phase power and produced dc to possibly give variable speed. Have some where i currently work but no longer in use. Robert Binius: Randy Cooke also used a lot in older mills with DC cranes to supply crane rails and large horsepower high torque dc mill motors etc. John Slowikowski shared Bill Beatty: The article says Weirton Steel is now being torn down completely. That's not true. The Primary end is all gone or almost gone. 9 Tandem, 5 Pickler, and the Tin Mill are still in operation and owned by Cleveland Cliffs. |

|

| Chris commented on his post Part of Weirton Steel while still active, the photo probably dates to the 1960s. |

|

| Jack Robinson posted Weirton Steel Company, Weirton, West Virginia. It was founded in 1909 by Ernest T. Weir and had employed 13,000 employees. It now employs under 1,000 employees. I retired from this mill and it was a great place to work. [It has 106 comments. I did not attempt to read them.] Jack Robinson posted again |

|

| Steven Heselden posted Weirton Steel Weirton, West Virginia November 2015 |

|

| First of thirteen drone photos posted by Bubba Dubs The 2008-2009 depression was really tough on the steel industry. The writing was on the wall by then for Mingo, but at least the EAF and rolling mill survives. Something is better then nothing. Makes you wonder if the plant in whole would have been able to survive in whole had OAO Severstal not sold the plant, and RG steel not going bankrupt in 2012?  Author Ian Hapsias it was rough with these landlocked mills and getting raw materials into them at a competitive cost against mills with lake transport. Also Steubenville was very archaic in nature as far as facilities went. I remember for a short time after Wheeling Pitt shut down the Steubenville furnaces, they were hurting for hot metal and was looking into trying to get one of Weirton’s furnaces up to help. Now I don’t think for a minute Arcelor Mittal would’ve been game but that was word on the street in 2006-06. Author Ian Hapsias Mingo #5 was completely re-lined only to be fired up for a short time or not at all! She was a good furnace for her size and very efficient but not big enough to satisfy the BOF’s hot metal appetite when it was running.Bubba Dubs Hey, I am looking at drones right now. Your photos are great. What kind of drone to you have and you satisfied with it???? Author Richard Allison yea very satisfied. It’s a DJI Mavic mini and even though it’s small it does everything I want it to!I think the only part of Weirton that is still running is the Tin Mill. My dad was one of the original melters at Weirton when they opened the BOP. Never believed as a kid that I would see the day when it would all be gone. I can remember those big furnaces running at full capacity when I was a kid.  Author Joe Buchanan correct, that’s the only thing. I believe they get their metal from Cleveland’s mill.are they replacing them with smaller capacity electric furnaces? Ryan MX Murphy no, Arcelor Mittal shut the plants hot end down for good in 2005? Not 100% sure on the date. But somewhere in that time frame nonetheless. Only thing that’s left is the tin mill which employs close to 900 people.Yes that is sad. One day they may need Blast Furnaces.  Author John Orlando the way they’re going with HBI (hot briquette iron) and electric arc furnaces maybe. Maybe not.I always think about it this way. Steel is the worlds most recyclable material. Surprised that those stoves are still standing. Furnace No. 1 was one of the first major structures they dropped. This demolition has been going on for over three years now! |

|

| Roger VanGosen commented on Bubba's post |

|

| Corey Williams commented on Bubba's post Still there on google maps satellite image, probably won't be next year. Thanks for sharing an update bud, very much appreciated. |

|

| Satellite Corey got better shadows than I did. Does Google use different images for its smartphone app vs. a web browser? |

|

| Mike Maddog Madigan commented on a post Shot from the roof of Weirton’s BOP.  Author Mike Maddog Madigan that was a cool place up there! I found that area when I got in there in 2014. There was a chair up there most likely for smoke breaks.They are in the process of replacing the EAF with a new updated one. [Since the post is about Mingo Junction, I don't now if he is referring to Mingo Junction or Weirton.] |

|

| Anthony Scurti posted Sherry Dborwski posted Weirton Steel Corporation - Weirton, WV |

|

| Jim Kamppi commented on Sherry's post Took the mill but left the gate. |

|

| Kevin Nelson posted, Facebook resolution An old National Steel Corp ad featuring Weirton Steel Co. Don't know the date. Kevin Nelson transcribed the text to make it more readable: Men and mills of Weirton Steel Company are an important part of National Steel's productive might Weirton Steel Company, one of the two major steel-producing divisions of National Steel, is the world's largest independent manufacturer of tin plate for the billions of tin cans America uses each year. Its record of contributions to improved steel-making methods is a proud one. Weirton helped develop the electrolytic process of coating steel with protective metals... today operates the largest and fastest electrolytic lines in the industry. Weirton installed the world's first fully continuous 4-high hot strip mill... pioneered many other improvements now standard in modern steel-making practice. Weirton is an integrated, versatile steel producer-from blast furnace and open hearth operations through complete rolling and finishing in its mills. Its products include a wide diversity of finished steels used by practically all of the nation's manufacturing industries. Weirton Steel is one of the seven principal subsidiaries of National Steel, fastest growing among America's large producers of steel. Dennis DeBruler: I've noticed that it said Weirton had a mill in Steubenville, OH. I've come across the names of Wheeling Pittsburgh Steel and LaBelle Iron Works for Steubenville. Are these different corporate names (ownership) for the same mill or was there more than one mill in Steubenville? (I know that JSW now owns the Wheeling Pittsburgh Steel mill and calls it Steubenville North.) Andrew Stewart: Dennis DeBruler Weirton had a small operation just north of Wheeling Pitt. Actually next door. Mike Maddog Madigan: Dennis JWS Is re working the Mingo BOF, now I think its going to upwards of a 500 ton EAF Their caster rolls two 96 inch slabs. Weirtons did four 48 inch . Kyle McGrogan: Weirton had a mill in South Steubenville next to the PRR River Line tracks. Donald Hall: Dennis DeBruler WSX had a tin mill sorting facility across Route 7 at the end of Slack Street. My Father in Law worked there for 42 years. They just called it, “The Steubenville Plant”. Jeff Roush: Mike Maddog Madigan when I was there the max cast width on each strand was I believe 70-80 inches Tom Mellott II: No. 1, 2 and 3 Platers. Only No. 2 plater is the only one still in place and operating. 1 and 3 removed a while ago |

|

| Kevin Nelson posted Another old National Steel Corp. ad featuring Weirton Steel Co. Edward Sivak: That was before the oil co. Pushed plastic down our throat !!! Pat McCon: Edward Sivak - Yeah, I think aluminum had more to do with it. If they’d learned sooner how to deep-draw steel so they could make 2-piece cans the story may have been happier. Aluminum did it first. |

|

| Digitally Zoomed |

|

| Weirton Steel Hometown posted Bill Bull Henry: no. 4 blast furnace John Slowikowski shared Used to sit there for hours to see this sight. |

|

| John commented on his share No 4 furnace after those vultures ripped her down in sept of 2017 |

|

| John commented on his share My firetruck on main st with no 4 furnace in the background |

|

| Mike Madddog Madigan posted WEIRTONS PIT SIDE , LOOKING SOUTH FROM CASTER FLOOR Billy Wafer: So what’s he 2 circles on the bottom of the ladle laying down? Dave Kurtz: Billy Wafer Weirton had a 4 strand caster. Two 2 strand tundish fed with one ladle. Thus the ladle had 2 NKK rotary gates to control steel flow. Billy Wafer: Dave Kurtz ….. we have a 5 and a 4 strand caster…. We use one gate. Dave Kurtz: Billy Wafer Weirton had big ladles…. In the range of 400 tons feeding two separate slab casters sitting side by side with two separate big tundishs. That’s why they needed two gates. I assume your 4-5 strand caster is billets/blooms or rounds? Billy Wafer: Dave Kurtz … billets and dog bones |

|

| Allard Edbert Edric posted Weirton Steel Caster w/400 ton heats - Nov ‘90 R Jim Echlin: That is one heck of a big ladle! |

|

| Mike Madddog Madigan posted WEIRTONS BOP MAIN GATE , NOTHING BUT A 40 ACRE DUST BOWL NOW Joe Buchanan Here is link to a video about this mill. https://youtu.be/891ZLMZehKY |

|

| Scott Izzy Israil posted Weirton Steel Hotmill Shawn Bane: #6 through #12 stands ready for roll change. |

|

| One of three photos that Ashlee Mercier-Speicher added to Scott's post Jim Easton: Good old 59 crane i miss that job. |

|

| Weirton Steel Hometown posted #4 Furnace after it was rebuilt in 1966 John Slowikowski shared All gone now |

|

| Comments on John's share |

|

| Jerry Goodwin posted Weirton Steel #4 Blast furnace second helper checking the iron level in the bottle. One of my favorite jobs in my 30 year career there. [There a lot of informative comments on this post. Too many for me to copy.] |

|

| Bill Cross posted, cropped I moved thousands of coils in my life at Weirton Steel. It’s 5 pickler in BWR. Casey Jacobs: I run a 35 ton crane with a c hook and a 38 ton with a coil grabber. I couldn’t imagine a double c hook. Pretty neat. Bill Cross: Casey Jacobs that crane was 60 ton. Once you get the hang of it you hate to just use single hook. [There are several more comments about the double hook. Evidently that is not common. Bill started 44 years ago with a triple hook. But coils were smaller back then.] Stan Karwoski: You coil guys might appreciate this. Responded to an accident once involving an 18 wheeler, he was hauling 2 coils & took the on-ramp/turn onto the overpass too fast & onto his side he went. The coils broke free as he went over and one of them went over the side of the overpass onto the road below and landed square on the hood of a car. When we got to the car, we couldn’t find the driver….then he comes running across the road towards us waving something in his hand & says “Sorry I left the scene, but after that (the coil on his car) I figured I better play the lottery before my luck runs out.” Unfortunately this was well before camera phones. The damage to his car was as impressive as you might think. The coil hit as close to dead center on the hood as you can get, it hit so hard not only smashed the engine like a grape it squirted fluids out from under the hood, not only was the block basically flattened but it drove the engine block (what was left of it) about 6” into the road & it all happened so fast it essentially tore the front end of the car from the fire wall causing pretty hardly any damage to the interior. |

|

| Stan Simich posted Last slab out of Weirton Steel walking beam furnaces in December 2007. This is #2 furnace in pic. Phil Elbaz: The Walking Beam was an excellent furnace. Made for Tin Plate. Never installed the Sizing Press. Never got the laminar flow to work quite right. Had to make higher strength properties with chemistry rather than thermomechanical rolling. John Carenbauer: Cooling system was poorly designed but we retrofitted it after ‘98 to get water temps down from 234F to ~174F if my memory is correct. Joe Valles: Is that different from the hotmill furnaces in the 70s ? John Carenbauer: Joe Valles yes |

|

| Bruce Russel posted The last days of BOP Weirton Rick Tennant: We used to go there just after it shut down. Looked like they just walked away...computers still on the desks, calendars on the walls frozen in time, almost pitch black in the daytime..Iittle spooky. |

|

| One of four photos posted by Bruce Russel BOP at Weirton Steel |

|

| Stephen Rauch posted M/V Sara Nicole working for Memco barge line in the early 2000’s…picking up barge loads of finished steel at the Weirton Steel Company dock - Weirton, WV. This piece of business was a perfect fit for the large fleet of roll-cover barges that Memco had recently built. Weirton Steel would load one barge per day M-F…and sometimes on Saturday…roll-covers only. [There are several comments about Weirton was one of the few docks who did a good job with roll tops.] Bud Osbourne: Spent MANY, MANY hours at that dock, over the years. Union Barge Line/Union-Mechling/Dravo Mechling was Weirton Steel's go-to barge line for decades. Dravo's Eastern Construction Division built Weirton Steel's two barge loading docks and their coal unloading dock. At one time, Weirton Steel loaded three barges every 24 hours, working round the clock. Besides UBL barges, they also loaded ACBL, Valley Line and Ohio River Company barges. But, UBL always got the lion's share of the business. Hard to imagine the volume of steel that was barged out of the Pittsburgh area. In the late 70s, Union-Mechling moved 90 barge loads of steel every month. Valley Line, ACBL and ORCO also did a fair number of steel loadings, but Union-Mechling was still the dominant barge line for steel. Of course, US Steel had their own barge line: Ohio Barge Line. They also moved an impressive amount of steel out of the Pittsburgh area. When the bottom fell out of the steel industry, in 1983-84, that pretty much ended it. Weirton cut back pretty drastically, but they managed to stay alive for a few more years. It's really sad to think of all the good jobs that were lost, forever, when "Big Steel" died. These days, there's probably more steel being barged INTO the Pittsburgh area than is being produced here. |

|

| Jerry Goodwin posted Weirton Steel #3 Casthouse. This was an ad for National Steel back in the 40’s when #3 was new and many thanks to Adams Antiques of Steubenville for sharing it. This scene was painted before the use of torpedo bottles and for dramatic affect the second helper has just thrown a shovel full of coke breeze into the iron ladle to check the level. It worked in the T-bottles also. |

.jpg) |

| Jerry Goodwin posted I found this print that sold on ebay pretty fascinating. If only I had a nickel for every time I climbed those stairs. Number 2 furnace was built in 1926. This is a painting of #2 furnace from 1936 before #3 was built. Note there were no "T" bottles at this time, just open top iron ladles. Kevin Nelson: https://www.foundimage.com/products/if-00156... |

|

| Sean Brady posted Operator checks General Electric duplex control panel which sounds a warning in the event of any malfunctioning of the motor room equipment. Weirton Steel Co. - 1957 [Those are motor-generator sets on the left. The mill motors needed DC so these were used to convert the grid's AC power to DC. I think the synchronous motors are on the left and the DC generators are on the right of each shaft.] Alan Taylor: Those cylindrical things behind the mans head are probably oil immersed breakers for high voltage (above 1000V). Motor Generator sets were used to provide DC for mill motors. To control the DC mill motor the field on the generator would be varied as well as the field on the mill motor. The sync motor provided a constant speed over a wide range of loads, Phase syncing was an added bonus to the system. Chuck Taylor: Just looking at this picture I can almost smell the lubrication oils, the Electrical control equipment and even the wiring. Every motor room I've been in was clean like this you could eat off the floor. I don't recall what those four black panels are? anyone? Fred Lannert: Chuck Taylor Those are Edwards Annunciators. Merritt Burrus: it would probably surprise a lot of you to know that there are many control panels just like this one, produced by ge, still in service around the US Jerome Wasil A.S In electronic tech worked in Industrial electric power all my adult life. While the machines on left may be MG sets, large synchronous motors had another common purpose back then... Nicknamed " rotary capacitors " Plants with large numbers of induction motors, developed a VERY low ( lagging) power factor. Not only did Utility Companies charge more for this type of load, many other electrical problems arose if POWER FACTOR below say 60%. Oversized expensive wiring needed, larger transformers main breakers/ fuses, etc! Synchronous motors RAISE the power factor, just like big banks of capacitors do. Also, the large heavy spinning rotors level out surges/ spikes in demand from other motors starting up.. Jerome Wasil Merritt Burrus In New Orleans La where I live now, many parts of the City, are below sea level. Therefore after any rain event, or for that matter huge storms, water must be removed by mechanically pumping, " lifting " billions of gallons to nearby lakes. Salient point is, this is acomplished with a series of quite old drainage pump stations, the largest of which have up to 5000Hp 25Hz synchronous motors, turning axial flow " woods screw pumps " As the grid supplies 60hz, two methods are employed: The water utility ( S&WB) has very old steam turbine/ generators, and 7.6Kv gets distributed on separate poles, etc to the stations! 2... mechanical frequency converters turn purchased 60hz voltage to 25Hz. No other motor but synchronous types could operate at the very low RPM and great torque needed to spin the giant horizontal shaft pumps. I'm unsure, which dept, this motor room was in but it had to be the cleanest area of Weirton Steel. Jerry Szczepanski: Things are getting pretty foggy after all these decades but if that really is at Weirton Steel it would have to be the Hot Mill Finishing Mill Motor Room, probably on the day before a tour by a bunch of big shots. Philip Varner: All motor rooms were that clean at one time…. |

|

| Rich Ribarevski posted Scanning some old pics from 1986, got me wondering the reason for ingots at Weirton Steel. They did have a continuous caster any other reason? https://youtu.be/891ZLMZehKY Rich Ribarevski: caster opened in late 60s Brian Olson: I was told that Weirton had a first generation caster and they were limited in how much they could push through it. It wasn't until the early 1990s that they were able to stop all ingot teeming and become 100% continuous cast. Lee Bradshaw: We still have dozens of customers who insist on ingots, aerospace, stainless and bearing steel mostly, better grain than con cast structure apparently. Craig Rusty Delanta: They did both. They had a 4 strand caster and also poured ingots for the blooming mill. Richard Peoples: In those days, only rimmed and capped grades of ingot-cast had good enough surface quality for tinplate and other critical -surface products. [Several comments indicated that ingots were teamed if the caster broke down. I wonder what they do in plants that were built from the beginning to use a caster and didn't have the ingot mold train infrastructure still around. I guess they have multiple casters.] Kevin-Marlene Lesnansky: Weirton's 40" blooming mill was run by a very large ( not tall ) steam engine till it was shut down 1992 or so. [According to some comments, some plants still bottom pour ingots.] Ernie Woolsey: Is this mill in operation? Scott Gracie: Ernie Woolsey , only the tin mill.....steel comes from a Cleveland Cliffs sister plant. Although they began casting slabs at Weirton in the late '60s, they simultaneously rolled slabs in their Blooming Mill into 1992. Arcelor Mittal choked off all hot end operations around 2005. The BOP (BOF), all four blast furnaces, sinter plant, blooming mill have all been leveled at Weirton. Kyle McGrogan: Also, the site of the BOF/BOP was where the old "Main Assembly Building" existed during WWII and for a while thereafter. Few people remember that it was used to manufacture 8" artillery shells for the US Army in WWII, (Weirton won a War Department "E" for their work, as it took them less then 6 months to completely retools the plant to do that work) and Weirton also rolled tie plates, spike and other rail fittings for the Russian Railroads just before WWII. My dad helped cut the dies for the tie-plates, and when I ran into a "Weirton" marked one from just before WWII on the PRR, I always thought of him. There is a Trolley crane and Boston Elevated Railway dump car at the Pennsylvania Trolley Museum in Washington , PA that has "Weirton" marked structural steel items in the underframes... Another specialty we forget about Weirton doing today! The sections were fairly heavy and are marked for Weirton with the year of rolling. Mike Matthes: I was always told the grain structure in some specialty steels was much better coming from ingot. Pat McCon: Mike Matthes - As we were building the second caster at LTV Cleveland there were customers who insisted that they still wanted ingot steel. Those who couldn’t be convinced otherwise were kissed goodbye and sent to the specialty producers who were in that business. Edward Talmadge: Caster down days and breakouts you poured ingots and the shop kept operating. Pat McCon: Edward Talmadge - Not so critical now - the ladle met facility can keep the steel hot in the ladle until the caster is ready again. No need to waste labor and energy teeming ingots just to use up the steel in the ladle. Art Wright: Casters breakdown, ingots can be remelted. Steel has to go somewhere its like a river. Caster stops, steel shops and blast furnaces have material already processing. Pat McCon: Art Wright - Not anymore. You finish the blow at the steel works, pour it into a ladle then send the ladle to the reheat station where it can sit and stir forever, and get an ard whenever it starts to cool down. Take the blast furnace off wind, and fix the caster. Nobody can afford to keep a teeming aisle, mold yard, striper, rolling stock, and a crew standing by just in case, only to scrap the ingots and remelt them. It sounds simple, but every non-value-added operation adds cost to a product that doesn’t have all that much margin to begin with. That’s why they measure yield. |

|

| Jon Wolfe posted Bryan Hockenberry: I remember the scarfer stack with the orange smoke coming out of it at the 44inch blooming mill in Mingo Jct Ohio in the late 70s. |

Wally Adyniec posted two photos with the comment: "Inside Weirton Steel BOP. All gone now."

|

| 1 |

|

| Laura Beth Dineen Anderson posted Weirton Steel, Tin Mill. My great uncle Frank Lorenz in the Weirton Steel Employee Bulletin 1951. (Weirton Area Museum online archives) |

|

| Jessica Van Giana posted Weirton Steel Machine Shop Steel works circa 1972. Bill Carnahan also posted with the same comment Frank Barbara Gaich: When this machine shop moved to the Main Street location, it became the new location for Steel Works Company Garage. |

%20Steel%20Mill%20Pictorial%20_%20Weirton%20Steel%20Machine%20Shop%20Steel%20works%20circa%201972.%20_%20.png) |

| Comments on Bill's post |

Mike Heilman posted eight photos with the comment: "Weirton Steel Blast Furnace outage. We repaired bells, hoppers, complete large and small bell rods pre-assembled in shop, then again in place. Large gears are from the BOP 400-ton cranes gearbox, another Machine shop staple."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| The Beauty of Steel posted Weirton Steel back in 2015 when I squeezed in on the Halooweeen eve. |

Austin Angus posted 10 photos with the comment: "Weirton Steel BOP construction."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 Completed BOP |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

Anthony Babiak posted two images with the comment: "Weirton Steel, 25,000 horsepower steam engine. They scrapped the beast a couple of years ago. When I was a machinist we were always busy making and repairing spares for it."

Sébastien Fel: What did this engine used to run? An electrical generator I assume?

Anthony Babiak: Sébastien Fel, Strictly mechanical. it ran our blooming mill. The blooming mill rolled steel ingots into slabs. The ingots would be rolled back and forth through rollers which gradually pressed them into shape. The steam engine was perfect because it could be reversed instantly. The blooming mill was eventually shut down in favor of continuous slab casting. Imported steel finally shut us down. The whole mill is gone now. It once employed over 13,000 people.

Dave Klink: WOW! What a vivid memory that brings back! I watched, listened, and thrilled to the action of that beast for the several years ('78-'81) that I worked in the Weirton Steel blooming mill that it powered. Somewhere at home I have a beautiful large industrial scale drawing of it. It was done by a man of great intellect and multiple talents, a "heater" in the blooming mill named Joe Duckworth. A "heater" was a soaking pit furnace operator.

Dave Klink: It was a 25,000 hp instantly reversible steam engine. Via a huge gearbox feeding two large counter-rotating driveshafts, It DIRECTLY powered the rolls of a "blooming mill" which is a mill that "blooms" hot steel ingots into "slabs" which are longer thinner pieces of steel that are further processed by other mills producing structural steel (beams, etc.) and/or sheet metal (think cans and cars). The two rolls that you see the hot ingot going into at about the five minute and 13 second point, were powered by this engine. If you have the brightness set high enough you can see the two driveshafts that are connected to the rolls. If this doesn't look too impressive on the video, it's only because the video does not seem to convey the size, weight, density, and heat of the steel that is being compressed and/or otherwise managed in this plant. The guy that you see working the large lever at about the seven minute point is the "engineer"/ "engine man" He is controlling the engine in real time via that lever. The center position is zero power, and it's functionally a continuously variable "throttle" in the forward and reverse directions. The man in the center is the "roller" and he's actually the head of the production operation. There's a lot more to it than it looks like, and even in the 70s mistakes could be catastrophic and cost multiple millions of dollars to fix. My grandfather was a "roller" for decades. He retired in 1974. The guy doing the dance of multiple hydraulic valves is the "manipulator". He is moving the multiple plates, hooks, cams, etc. that optimize the position of the ingot before it is drawn back into the mill for the next step. Turning an ingot into the exact slab size ordered involved multiple flips and pulls through the mill. The steps required were calculated so that a certain precise combination gave a desired result, and the roller was the guy that had to make sure all of that happened. He had to be constantly aware that the dimensions he was seeing on the large sliding gauge were an exact representation of the reality at the roll surfaces. As you can imagine, a team of "millwrights" were constantly checking, cross checking, and adjusting all of this machinery to ensure that something so large, heavy, and unwieldy could be operated with predictable and profitable results without anybody getting severely injured or killed.

[There are more photos and video links in the comments. Fortunately, this post is in a public group.]

Rick Glover shared

Jeff Lawrence: Worked on it a few times…changed parts.which were always extra large..that job fell to the rigging gang..but a pleasure to work on a piece of history..no electric motor was ever fast enough to do the reverse motion of the rolls.

Bill Carnahan: As a machinest we would crawl in the cylinders to mic the bore on their down time. Hot, laying on boards and rags.

|

| 1 [I'm glad they included a person to provide some scale.] |

|

| 2 |

|

| Rick Rowlands commented on Anthony's post HP and LP piston rings and a Honda |

|

| Rick Rowlands commented on Dave's first comment |

Joshua Denham posted 18 photos. The tin plate mill still exists and is now owned by Cleveland-Cliffs.

6 photos including interior "Phelps Can Co. Largest Makers of Milk Cans"

A 23:36 video about supporting the WWII effort The title has a date of 1940, but the narrator says the story began back in 1944. Every time I watch a WWII PR video concerning steel production, I'm reminded that China now produces about 10 times as much steel as does the USA.

A 32:51 1987 video If they hadn't added "music" to the narration, the first half would have been a really good video. I think the second half is a repeat of the above WWII film.

13:55 video in blooming mill It starts with stripping some ingots and putting them into soaking pits. Then taking ignots out of the soaking pits. Then an ingot is run back and forth in a reversing stand. And then some guys pushing and pulling levers. I then saw a slab, but I could not figure out what was happening. Continuous casting made this mill and the teaming house obsolete. (The teaming house is were they poured the molten steel into ingot molds.

6:27 YouTube video of the demolition of the BOP (source) Skip to 1:30 for the action. You can see it start to fall before you hear the booms. At 2:38, a cloud of dust must have bounced off of something and blew across the road. Even at 6:23, the cloud of dust was still huge. I guess the good news is that they must have picked a day with no wind so that the dust stayed over the site.

Greg Savernik: City of Weirton was taxing the company for the structure and scrap value was up so they decided to take as many buildings down as possible to limit their tax bill. Sad but true. Wish they could have continued. USS Greatlakes HSM is now scheduled for demolition too. All the work we did there wasted.

John Slowikowski: Greg Savernik wasn’t the city it was the county. The city however was adamant about that fire and police fee being paid.

That fire and police fee is a joke. Spent many years with the Weirton fire house and asked where that money was going and got treated like I was crazy.

Kyle McGrogan: The BOP was not missed much. When installed in Weirton and fired up for the first time, the sound of the air being sucked into the furnace was ferocious! They later fitted the mufflers ( the upturned arms) to minimize that noise. In about 1976, when my day retired from the old 5" Strip machine shop, about 7,000-8,000 people worked at Weirton Steel, now it would be doubtful if they have 400, and it no longer can roduce its own steel. Weirton is no longer the mill, or the town that it was 50+ years ago!

2 videos of a crane removing the BOF hot metal crane One of the main hoist drums is being pulled.

Bill Skiles: BOP and there where 7 650 ton cranes.

Bill Super: ArcelorMittal was going to refurbish and reinstall in Chicago. Never happened. They found too many cracks in girders. Ended up taking motors and drums to Chicago and had been storing girders in Weirton. Everything else went to demo contractor.

Steve Kashuba: Great picture. I heard they had to repair and clean all the homes behind there. So sad.

0:37 video panning the plant from "on top"

6 photos from 2013

7 photos of the ruins of the #5 Galvanize Line

Jan 2026:

Alex Taylor - WTRF 7News posted three photos with the comment:

🚨 BREAKING UPDATE 🔥🚒An active fire is drawing multiple crews to West Virginia Steel & Tin Mill right now.We’re receiving photos and video from witnesses as the response continues. We’re working to confirm details and will update you as soon as we learn more.🔗 WHAT WE KNOW: link is in the comments.

Alex Taylor - WTRF 7News: THE CAUSE: “They’re doing a lot of scrap work, and they’re getting ready to tear some stuff down. They were burning with a torch, burning some bolts, which then caught a big plastic tank on fire.”

KEVIN HIMMELRICK | CHIEF, WEIRTON FIRE DEPARTMENT

|

| 1 |

|

| 2 |

|

| 3 |

"Due to the closure of the mill in April 2024, all the utilities were shut off, including their water." Thus they had to call for a tanker task force. [wtrf_blowtorch]

Cleveland-Cliffs idled the plant on Apr 20, 2024. [wtrf_idle]

No comments:

Post a Comment