See the W&LE Bridge for more views of this area.

I hope the Facebook group stays public because there is a lot of information about Republic Steel Bolt & Nut Division in this post.

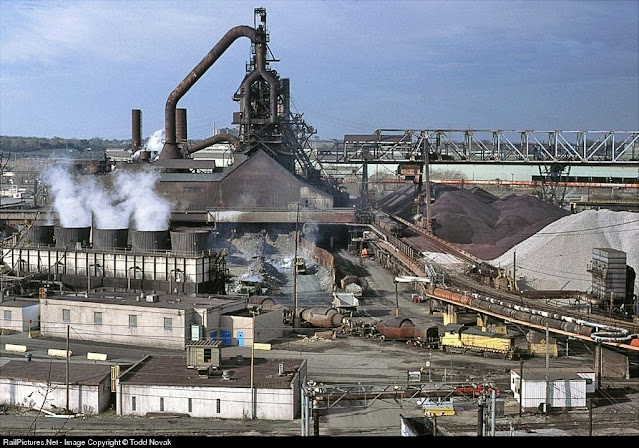

Matt Celeste posted 3 photos with the comment: "Cleveland-Cliffs East plant in Cleveland, originally Corrigan-McKinney. (12/2/22)"

Bubba Dubs posted three photos with the comment: "Cliffs Cleveland C5 and C6 back when they had the coke plant, and today without. Original photographer unknown, drone pics by me."

Steve Koczan posted two photos with the comment: ''This is a sign of Cliffs continued investment in Cleveland's Blast Furnaces. Outer shells of the new stoves being offloaded."

I wonder how much total horsepower these synchronous motors were rated at. This is why power companies would offer lower electric rates to mills that were willing to shutdown during days that had a high electric demand. In the north, these days occurred on hot days. I'm sure the workers did not mind taking off sweltering hot days.

Unfortunately, the two ore bridges don't show up very well in this satellite image. But Viktor Macha has a nice photo that shows the bridges and the blast furnaces.

|

| 3D Satellite |

|

| The Beauty of Steel posted Cleveland blast furnaces, 10/2015 |

|

| Jonathan Thomas posted C5 & C6 blast furnace Cleveland summer 2021 |

|

| Kajal Chauhan posted Jones And Laughlin Steel Corp. Cleveland Works Steel Cleveland (Ohio). [Judging from some comments, this was J&L's C2 and C4 on the east side. On the west side was Republic and their C1 and C3.] |

|

| Fort Frick Photography posted Cleveland Cliffs Blast Furnaces. ~~~~~~~~~~~~~~~~~~~~~~~~ PRINTS: www.fortfrickphotography.com ~~~~~~~~~~~~~~~~~~~~~~~ |

|

| Mtnclimberjoe Rail Photography posted A pair of Cleveland Works Railroad jobs meet deep inside the steel mill complex at the Cleveland Cliffs Cleveland Works in Cleveland, Ohio. A solo SW1500 hauls the bottle train towards the slag dump to be emptied, while a pair of SW1500's pulls empty slab gons from the interchange yard with NS to take towards the mill for loading. These bridges crossing the Cuyahoga River mark the end of the navigable channel for freighters, which unload ore here for the mill. ====Info==== 4/9/2023 Cleveland Cliffs Cleveland Works Cleveland, OH Unknown Symbol (Empty Gons; Cleveland, OH) CWRO 1555 SW1500 Ex. WC 1555, SP 2640 Blt. 1972 CWRO 1551 SW1500 Ex. WC 1551, SP 2505 Blt. 1968 Unknown Symbol (Bottle Train; Cleveland, OH) CWRO 1554 SW1500 Ex. WC 1554, SP 2594 Blt. 1970 James Torgeson shared Pat McCon: Those bridges also mark the spot where the debris on the river caught fire in the famous event. |

|

| Ross Patterson posted I went to a craft show in Seven Hills and got this picture from a professional photographer there. Just framed it. Thought you would appreciate. |

Edmund Pilarski posted three images with the comment: "Republic 98" strip ("largest of its kind in the world. This mill is capable of producing over 200,000 tons" per month.) Cleveland Ohio."

|

| 1 |

|

| 2 |

|

| 3 |

|

| Richard Wagner posted Industrial Vally with the Cuyahoga River in the 1950s. Mark Adamcik: These are the original Corrigan-McKinney blaast furnaces, North of Clark Ave. on the West bank. James Toregeson shared [According to some comments, Republic in the foreground and Otis Works in the background.] |

|

| Dennis DeBruler commented on James' share It appears the Republic mill buildings is still standing. The skyline sure has changed. |

|

| Thomas Flynn posted Kenny Branning Sr.: Working at A , BOF now. |

|

| News 5 Cleveland posted Industrial view of Cleveland this [Oct 24, 2022] morning from the steel mills. Joshua Ames shared [Summarizing some comments: Cliffs/ArcelorMittal/Mittal/ISG/LTV/Republic/J&L/Otis] Jf Hull: Not much left. Riley Harrison Braun: Jf Hull they're only showing steel producing 1 in this picture. Not pictured is blast furnace, finishing, hot mill, and steel 2. |

|

| Jon Wolfe posted Dan Kleinhenz: What do the red and green highlights represent? Bubba Dubs: Dan Kleinhenz red are no longer in service and demolished. Green still going. Where number 2 finishing was, is now steel yard commons with various restaurants and shopping |

|

| Gabina Onthe Road commented on Jashua's share the old stompin' ground .... |

|

| ClevelandHistorical Founded by Charles Otis in 1873, the company was the first in the United States to produce steel in an open-hearth furnace. By the end of the nineteenth century it owned and operated a mammoth complex of mills, warehouses and office buildings that stretched along the Lake Erie waterfront from East 25th to East 40th streets. For years, it was one of the major employers of Polish immigrants in the Josephatowa neighborhood. Otis Steel was later purchased by Jones & Laughlin, who closed the company's lakefront operation shortly after the end of World War II. Today, much of the land upon which Otis Steel was once located is occupied by the Innerbelt and the Memorial Shoreway, including the infamous Deadman's Curve. This photograph of the complex was taken in circa 1910. | Source: Cleveland Public Library, Digital Gallery |

|

| Thomas Flynn posted Old LTV West. Now Cleveland Cliffs. |

|

| Youngstown Steel Heritage / J&L Narrow Gauge Railroad posted Our Morgan crane is the oldest electric overhead crane in existence. Built in 1893 for Otis Steel in Cleveland. Rick Rowlands shared One of only two rolling mill steam engines still in existence and the oldest overhead crane in a building that I built for them in 2009. [There are several interesting comments about other big steam engines and old overhead cranes.] |

|

| Raymond Boothe posted Cliffs Steel-Cleveland Works: Night view of Cleveland blast furnaces No. 5 & 6 unkn/Camino photo/Dr. Raymond Boothe collection). |

`

|

| Raymond Boothe posted Cleveland Cliffs-Cleveland Works: View of No. 5 blast furnace (Macha photo). |

|

| Steve Griffin posted 5&6 bf. Cleveland works Republic Steel |

|

| Roland Nrw posted "ArcelorMittal." Full HDR Gary Tischler: Cleveland works |

|

| Raymond Boothe posted Cliffs Steel-Cleveland Works: Hot strip mill rougher. Cleveland currently is the most efficient integrated steel mill in the United States (Macha photo). |

|

| Raymond Boothe posted The Otis Steel Company-Cleveland, Ohio (Later J&L-Currently Cliffs Steel): View of the 77" hot strip mill (Otis photo/Dr.Raymond Boothe collection). |

|

| Raymond Boothe posted Cliffs Steel-Cleveland Works: View of the No. 2 steel making shop (unkn/Dr. Raymond Boothe collection). |

|

| Phil Jadlowiec posted Cleveland Cliffs |

|

| Phil Jadlowiec posted Sharing from another group Cleveland Cliffs |

.jpg) |

| Jon Wolfe posted Cleveland cliffs Russ Potyrala: Why are flammable gases just vented off & burned instead of reused to help capture the wasted heat? Frank Beckloff: Russ Potyrala actually 70-90% of furnace gas is used in steam boilers for electrical generation, and plant steam for heating and other purposes, at least in Cleveland. The btu content of the furnace gas is abysmally low which presents challenges...but it IS burned. Patrick Connelly: Frank Beckloff i know u r referring to blast furnace gas. Not the SC gas shown in this photo. Ran the powerhouses for many years. Patrick Connelly: Russ Potyrala helped install this suppress combustion system in 1977 to reduce pollution during steel making process. Flared gas is cyclic and difficult to capture. Much better than the red sky we had previously over Cleveland. |

|

| JC Kaczmarek commented on Jon's post, cropped |

|

| Mark Reichert commented on Jon's post, cropped Dennis Beno: Mark Reichert now that’s a cool pic! Obviously blowing a heat on #1 Vessel at the East Side Melt Shop. |

|

| Jim Hartland posted My grandfather, Jim Hartland, electrician at J&L Steel, Cleveland Ohio Charlie White: It's amazing really how quickly electricity went from being a laboratory physics experiment to a mainstream, heavy-duty necessity of life. |

|

| Jim Hartland posted My grandfather, Jim Hartland, electrician at J&L Steel, Cleveland Ohio Kevin Carey: AC synchronous motor driving a DC generator. I remember we used these MGs in a wire mill in which I worked. John Kot: As a young engineering student, I worked for a short time in a steel mill that used the same system: a synchronous motor driving a DC generator, which powered the primary rolling mill. The big DC motors would reverse as the steel ingots went back and forth between the rollers. There was another synchronous machine that didn't appear to do anything. I asked the engineer in charge what it was for and he explained that it was there for power-factor correction. Phil Jadlowiec: All the resistor banks on top of the switch gear |

|

| Keener White posted Cleveland in the backdrop David Craven: It is C5&6. The view is at an angle from the road in yucca flats. It looks like C5 has new stoves and the dust catcher looks like it was moved. |

|

| John O'Neil commented on Keener's post When the siding was replaced, they made it look like the poop emoji. |

|

| Bob Collins posted, cropped This is a aerial photo of the two Cleveland Steel Mills; J & L and Republic Steel. For reference the Cuyahoga River bisects the photo. Republic Steel on the top or east side of the river and J & L on the bottom or west side. It also shows the Treamont neighborhood on the northwest and some of the Harvard Ave neighborhood on the southeast.. I'm guessing the picture was taken in the late 60s after the J & L 80" HSM was built. |

Jim Votruba posted a 2:09 video of the working rolls being replaced.

Jeffery Meeks: We had our rolls set up on a turntable . Take the old rolls out , turn the table 360 degrees put new rolls in. Didn't need a crane until new rolls were in the mill and mill was already back to rolling steel. Inland Steel baby!!!

Robert Meyer: You mean 180 deg. Notice roll bending but no thrust bearing, bad combination.....

Bob Collins: Robert Meyer we had no roll bending on the 80" finishing train.

[The rolls are reground and reused.]

|

| Thomas Flynn posted Now Cleveland Cliffs. Cleveland Ohio. |

|

| Tommy Herdman commented on Tommy's post |

|

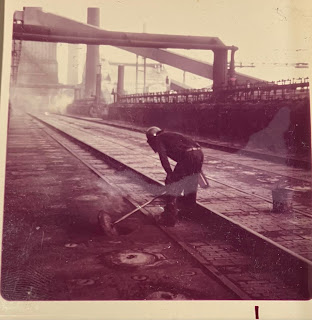

| Cool Ohio posted TAPPING OF FURNACE, SLAG RUN RIGHT FOREGROUND Corrigan-McKinney Steel Company. 3100 East Forty-fifth Street. Cleveland, Ohio. 1968. Bill Price: In 1968 that would be Republic Steel's #1 Blast Furnace on the west side. Worked there summer of 66 & 67. Cool Ohio: Bill Price the date might be wrong. i haven't been able to find an accurate date for the photo Cool Ohio shared |

|

| Raymond Boothe posted Cleveland Cliffs No. 1 steel making shop (BOF) in Cleveland, Ohio (Dr. Raymond Boothe photograph). |

|

| Map via 1965 |

|

| Map popup via 1965, East side of river, still standing |

|

| Map via popup 1965, West side of river, gone |

|

| Map via popup 1965, gone |

|

| Tony Margis posted At the Cleveland, Ohio Arcelor/Mittal plant. (Old Republic, then LTV) (undated) |

|

| The Beauty of Steel posted The 84" hot strip mill at Cleveland-Cliffs works, Ohio. Folks, if you like my work, find me on IG under viktormacha account. FB algorithms are getting more and more weird. The Beauty of Steel: some more images from there: Viktor Mácha: https://www.instagram.com/viktormacha/ James Lucas: When the 98 inch was there in the flats in cleveland we produced the widest armor plate hot roll in the world at republic steel. Stephen Pelkowski: Uncertain what I'm looking at... but absolutely lover it! Scott Rupp: Stephen Pelkowski rolling mills at the end of hot strip. Thick slabs are heated then run through mills to reduce thickness. Once it gets to the finishing end, it hits these rolls very fast and reduces to approx a tenth of an inch thick and is coiled. Richard Lindsay: One roughing mill & 6 finishing rolls ? Same as we had at Port Kembla / Australia Christopher Getts: Those are finish rolls they get changed a lot |

(US Steel also had a big presence in Cleveland, but it had major closures in 1978 and 1984.)

I first saw this steel mill as the destination for river ore boats. Steelmaking started on the lakefront in the 1830s. "In the 1870s, Otis Iron and Steel Co.’s Lakeside Works in Cleveland became the first mill in America to produce

commercial-grade steel with a new process, the basic open-hearth furnace." In 1912, Otis Steel constructed its Riverside Works. Corrigan-McKinney Steel Co also built a mill along the river. Otis was bought by Jones & Lauphlin Steel while Corrigan-McKinney was bought by Republic Steel. In 1984, LTV was formed as a merger of Republic and J&L. Two years later, LTV went bankrupt. But it bounced back in the 1990s. It spent $1.1b that included "LTV’s installation of a continuous process for

converting molten steel into slabs that are then processed into hot-rolled steel." But LTV went bankrupt again and shut down Nov 2001. Later, the International Steel Group bought LTV, along with some other bankrupt companies, and fired this plant back up with an agreement "with the United

Steelworkers to create a different business model that included more streamlined operations and very lean staffing." In April 2005, Mittal Steel merged with ISG. In 2006, Mittal added a hot dip galvanizing line that could produce 630,000 tons annually. Later in 2006, Mittal merged with Arcelor. "Today, ArcelorMittal Cleveland is one of the company’s largest facilities, covering more than 950 acres of land with

7,000,000 square feet of buildings. It is a fully integrated steelmaking plant with two blast furnaces that feed two

steelmaking facilities capable of producing 3.6 million tons of raw steel annually." The town had 374 steel workers in 1860 and more than 30,000 during the boom after WWII. [history (If the link has broken, the page has been saved at the bottom of these notes.)] I presume that "very lean staffing" is a euphemism for automation. The current employment is 1,863. [facts] Cleveland is one of the most productive mills in the world. It can produce a ton of steel for slightly more than one worker-hour. The industry average in the US is 1.9 worker-hours/ton.

Republic Steel's improvements included two basic oxygen furnaces in the 1960s, a modern hot strip mill in 1971 and a continuous caster that was commissioned in 1983. "The first slab cast remains on display outside of what is today known as #1 Steel Producing." [history]

|

| Map Raymond Boothe posted |

|

| James Torgeson posted [This map has lots of resolution. It is worth saving to disk and using your favorite photo viewer to zoom and pan.] This map is undated, but I’ve had it for about 15 years. Pat McCon: 1993-ish. That’s when the DHCC started up with the commissioning of the west side Caster. Prior to that the terminology was ‘#1 BOF’ and ‘Direct Roll Department’. Direct Roll referred to the coupling of the #2 Slabbing Mill and the 80” Hot Strip Mill, with no reheat furnaces between them. #1 Slabbing mill and the Coke Plants were decommissioned around this time and disappeared from later maps. |

|

| Rick Pietrick commented on James' post |

Susan Cz posted two images with the comments: "J&L Cleveland Works Map from the 1970's, and what is looks like from the air in 2010."

John Bondy: The only J&L facility still in operation from that map is the BOF shop. It is pre-caster.

|

| 1 |

|

| 2 |

|

| facts |

Bubba Dubs posted two photos with the comment: "Cliffs 5&6 now, and back in the Republic days. Thank you Don Weitzman for sharing the picture from back in the day."

[Interesting discussion about where they get their coke. The Republic side is in the photo.]

|

| 1 |

|

| 2 |

|

| Tommy Herdman posted The Mill of Cleveland at night |

|

| Thomas Flynn posted, cropped C-3 Susan. LTV Cleveland. Before she came down. Lyle Zerla: In 1960 there were 450 blast furnaces with in a 50 mile radius of the point in Pittsburgh. Today 1. |

|

| Kevin Beck commented on Thomas' post Here’s the top view of C6 a few weeks ago. |

|

| James Torgeson shared a Fed Bultman post A busy shot looking west across the Cuyahoga at the Otis Works of Jones & Laughlin Steel. One of their ancient Brown Hoists is unloading Grand Island while a Great lakes Dredge & Dock dredge and dump scow are working on deeping the channel, an action that will spell doom for smaller freighters like Grand Island, for it will allow bigger boats to reach the head of navigation. 1958ish. Ross Patterson: I'm thinking not much if any in that pic is still there. James Torgeson: Ross Patterson The former J&L blast furnaces are gone. The two remaining BFs at the Cleveland-Cliffs Cleveland Works are former Republic Steel. Phil Leduc: That’s the Clark avenue bridge in the back ground, which means that’s C-1 blast furnace |

|

| Fred Bultman posted A ten ton hulett at Republic Steel in Cleveland, 1974. Fred Bultman shared Don Weitzman: Half went to the pit for storage behind the hulett then fed the furnaces by bridge crane and the other half went into Jennie’s that went to Youngstown. |

|

| Don Weitzman commented on Fred's share A backside view |

|

| Don Weitzman commented on Fred's share A better view |

Austin Corlett posted four photos with the comment: "LTV's DHCC - Cleveland Works 1993. Now Cleveland Cliffs West Side Caster."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

This post motivated researching this plant.

|

| Andrew Jones posted, cropped 16,000HP roughing mill electric motor at the hot mill of Arcelor Cleveland. Removed during a down turn for cleaning. Hector Soto: I work in the cold mill at Arcelormittal Indiana Harbor. Our sync motor is 25,000 HP and runs 7 generators. Kevin Daffey: Mill motors are one of the toughest applications for an electric motor. Especially hot rolling or roughing. Several times their nominal torque required every time the head end hits the mill! [Some comments indicate that it is a 450 rpm synchronous motor, probably at 13,200 volts. It runs a roughing stand in the hot mill.] |

And then I found this posting.

Dane Rubsam posted thirteen photos with the comment: "Some pics I took at the Cleveland, Ohio Arcelor/Mittal plant a couple yrs ago. (Old Republic, then LTV)."

[A Facebook comment indicates the stands were made by Mesta Machine.]

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 [I don't think I've ever seen the motor side of the rolling stands before. The thickness of the shafts shows what it takes to handle 16,000 hp.] |

|

| 11 |

|

| 12 |

|

| 13 |

Dane Rubsam also posted a video of an ore bridge working.

|

| One of four photos posted by Daniel Short For those that love history... Margaret Bourke-White was a pioneer in photography. Specifically industrial photography. The date of the older pictures are 1928 (I believe). Of the teeming aisle at (then) Otis Steel in Cleveland Ohio, which she did a whole series of photos. The last picture is today, of the same teeming aisle (by name only) 92 years later (Arcelormittal Cleveland... soon to be Cleveland Cliffs). Though we've seen better days, still running. [The teeming aisle was evidently where they cast the ignots. With continuous casters, that function has now become obsolete so it is now used for ladle storage.] |

|

| Fred Bultman posted The Otis works of Jones & Laughlin Steel, in the late 1950s, J&L had their own fleet of freighters, Interstate Steamship Company, until the early 1950s. Now an empty field in the flats. |

|

| Tom Krejny posted Republic Steel Cleveland Stripper Building - 1972 Cory Moyer: Sam Moyer east side or west side Sam Moyer: Cory Moyer east side I believe that building housed the skull cracker punched ingots out of the molds before the caster jones and Laughlin LTV west side before we merged |

|

| Paul Warthling commented on Tom's post And the Steam Engine that drove the 44" Mill. |

|

| Paul Warthling commented on Tom's post And the Steam Engine that drove the 44" Mill. |

|

| 1953 Cleveland South Quadrangle @ 1:24,000 |

|

| 1970 Cleveland South Quadrangle @ 1:24,000 |

Matt Celeste posted 3 photos with the comment: "Cleveland-Cliffs East plant in Cleveland, originally Corrigan-McKinney. (12/2/22)"

Theresa Rice: You should have seen in the 70’s and 80’s. Two coke plants, a bar mill, ingot production as well as a caster and four blast furnaces. Oh and five open hearth furnaces.

And I forgot the 45” slabbing mill and the 44” billet mill.

John Groves: Merged into Republic Steel in 1935.

Sam Burkett: i see the engineering building in the background. Installed a hydraulicf dynamic roll bending system on their hot mill (first in the world). then later a tension leveller before the coldmill.

John Groves: Brief history of the Cleveland plants.....

What is now the Cleveland East plant was established by Corrigan McKinney Steel in 1910 and it was acquired by Republic Steel in 1935. It soon became Republic's flagship plant. Steelmaking capacity peaked at 4.2 Mtpa in the 1970s.

The Cleveland West plant was established by Otis Steel in 1913 on the opposite side of the Cuyahoga River. Otis Steel was acquired by Jones and Laughlin Steel in 1942. Steelmaking capacity peaked at 3.1 Mtpa in the 1970s.

In 1974 LTV Corp. acquired J&L Steel, which in 1978 acquired Lykes-Youngstown Steel (formerly YS&T), and in 1984 acquired Republic Steel to form LTV Steel. The two adjacent plants have been operated as a single unit since 1984. Ownership moved from LTV Steel to ISG in 2002, then Mittal Steel in 2004, ArcelorMittal in 2006 and now Cleveland-Cliffs in 2020. Effective raw steel capacity of the two plants may now be around 3.5 Mtpa, limited by the two remaining blast furnaces.

The above notes were extracted from a longer post I made about a year ago when I first joined this outstanding Steel Mill Pictorial group. The post outlined the historical context of the only remaining integrated steel plants in USA, five for Cleveland-Cliffs and then four for US Steel (now three, soon to shrink to two)

Bob Boardman: https://www.kentstateuniversitypress.com/2010/steel-remembered/

|

| 2 Sjaak Betjes: BOF shop? |

|

| 3 Dru Joslin: Not to brag but me and a handful of my brothers built these observation decks on these flare stacks some years back for EPA instrumentation . it was freaking awesome lol. |

|

| Ross Patterson posted Gearbox that tilts vessel in the bof. This is old J&L Cleveland. |

|

| Thomas William Cline posted, cropped View from my break trailer C6 ArecelorMittal Cleveland Jeff Sherrill: You work for a contractor...??? Job...??? Thomas William Cline: Jeff Sherrill 310 laborer for Precision Environmental. Scaling the furnace, clearing dust collector debris, clearing the bustle pipe, tending brickies and carpenters while they reline the stoves. I, personally, have been in the bustle pipe and clearing debris from the dust collector after it’s dynamited out and tending carpenters and ironworkers while they opened the furnace and assembled the dance floor to scale it. [Other comments imply they are preparing to bring C6 back online and c5 is active. Note the worker basket hanging from the crane in the photo.] Richard Allison: Are both C5 and C6 single taphole blast furnaces???? Jon Miller: Richard Allison C5 has two. C6 is single |

Bubba Dubs posted three photos with the comment: "Cliffs Cleveland C5 and C6 back when they had the coke plant, and today without. Original photographer unknown, drone pics by me."

Tony Pasquale: Great pictures, this is before they put the ramps in leading up to the furnaces. Everything had to be carried up by hand or with the 15T cast house crane. #5 only had one tap hole.

Bubba Dubs: Tony Pasquale I see that addition on the closest furnace. Is that C-5 or C-6?

Tony Pasquale: Bubba Dubs c-5

|

| 1 |

|

| 2 |

|

| 3 |

Tony Pasquale posted two photos with the comment: "Top of #6 furnace, overlooking ore yard, ore bridge and the beautiful cuyahoga river."

|

| 1 |

|

| 2 |

|

| Justin Marsh commented on Tony's post Downtown Cleveland behind the steam on the left, #5 and #6 to the right. |

|

| Todd Dillon posted C5 Furnace Cleveland OH [Note the torpedo cars in the middle foreground.] Ron Mamula: We’re going to rebuild her this winter/spring. My family has been doing this on BF’s all over America for over 100 years… Evan Manley: Where is this spot that you can watch this? I’ve seen others take photos from the location in this photo as well. Todd Dillon: It’s behind a trucking company which overlooks the mill. [From the roof of this building?] |

|

| Ronald Cumberland posted This is the BOF at the Cleveland works of Jones &Laughin works also around 1978 it still used by Arcel Mittal along with the slab caster as needed all the left of west side works. |

|

| Comments on Ronald's post |

|

| Thomas Flynn posted LTV West 1980s Cleveland Karol F Domitrovich: Station 14 was on the West side of the building, the bloomer was inside the door on the right. I almost bought it there back in 91. Jeff Toth: West side was J&L and East side was Republic? C1, C2, and C3 blast furnaces at J&L. #5 and #6 blast furnaces at Republic? Am I remembering that correctly? Andrew Shroads: Jeff Toth that's what I was told in the 00s. Kevin Kramer: I remember as a kid, sitting with my dad on the Clark Ave bridge watching the ingots being poured in the open hearth. My dad (former US Steel) told me don't you ever work in steel, you will be laid off more than you work. My dad had a fit when in 1988 I started at LSE, now 34 years later I never got laid off. Came close when LTV filed chapter 7 but never laid off. Brian Olson: Someone told me that J&L Steel Cleveland had a large, relatively new blast furnace that shut down. Maybe Susan. What happened that they would kill off a large modern blast furnace like that? Pierino Zappitelli: Brian Olson yes but the problem was it was leaning 11" a year. They took it down in 86 before it claped. Brett Deamon: Brian Olson we got 2 Blast Furnaces left 5 and 6 furnace. Both making lots of molten iron. Bob Collins: Walked in every day through the ingot yard, from bottom left to top right, between the Universal Slabbing Mill and the old Open Hearth Building, on to the 80" HSM. Paul Maier: One of the last places to get a caster. Brian Johnson: Looks like a mold yard .. I have nt seen one of those since around 1981. Todd Dillon: The buildings are still used by Cleveland Cliffs but the tracks are removed no more ingot cars. Sam Burkett: My friend and I installed the first dynamic roll bending system on their hot mill finishing train. Also a tension leveller. While at Mannesman Demag around 1990. Taught hydraulic classes to their maintenance workers. Karol F Domitrovich: North end mold yard. John J. Chapman shared Karen Cereceres Bates: Now home of Steelyard Commons. https://steelyard-commons.com |

|

| Ross Patterson commented on Thomas' post Looks a little different today. Notice the J&L still on the building. Hopefully Cliffs won't paint it blue. |

|

| Nick Pandolfi posted, cropped "Susan" C-3 blast furnace. The newest in Cleveland built by Khoppers (1963) One of the largest in the country. J&L/LTV literally ran it non stop and destroyed the infrastructure beyond repair. It was tore down in the early 90's. I scratch built a 1:43 scale version for my O scale train layout. |

|

| Nic Santana posted, May 30, 2021 Stuck at C5 in Cleveland on a Sunday. At least it's double time. Timothy Kish: It’s back up and running just not producing yet. I work for the electrical contractor that fixed. Took our crew 10 days to fix over 300 wires. 4 mcc line ups that were burned through. Timothy Kish: They’re having trouble remelting the material that was left in the vessel. Nic Santana: I wish I'd taken pictures of the north wall after it blew. I still have pipes covered in slag that I need to replace but the laborers cleaned that area up pretty good. Timothy Kish: Nic Santana yeah that crew break room too. That thing was totally torched. They’re so lucky no one was in there and no one got hurt. Nic Santana: I just walkrd in there today, it's crazy looking at the damage. I'm glad no one was hurt, I was just at the 84" at the reheat furnace working for Jason Davis running the night crew. Not good waking up to the GF telling me that he just fell in the slag pit. Thomas William Cline: i feel for you, got called down there the day the tweeters blew for “a one day cleanup” that turned into 7 straight 12s hammering slag off the casthouse walls lol Aaron Smith: Thomas William Cline "tuyeres" lol not tweeters. |

|

| Thomas William Cline commented on Nic's post, cropped looks like we were parking in the same spot |

|

| Don Weitzman posted Another load for Cleveland Brandon Proy: What year was this picture? Pretty sure that's an old ore bridge on the far right across from the furnaces that was demolished before I started 8.5 years ago. Don Weitzman: Brandon Proy you are correct. It is pre bankruptcy. I’m guessing 1998 or before the bottle job pulling the eight bottles is The River Terminal RRWy |

.jpg) |

| Jesus Green posted Cleveland, Ohio |

|

| Matthew Ryan posted My cousins 1953 F-100 parked at cleveland cliffs cleveland blast furnaces c5-6. |

|

| Michael Jones posted blast furnaces in cleveland, oh Steve Koczan: Nice shot of 5 and 6 |

|

| Tony Pasquale commented on Michael's post #5 furnace in Cleveland |

Myron Uehlein posted two photos with the comment: "Probably late 60's early 70's."

Brian Olson: I remember reading an interview where Tom Graham criticized various steel companies for building fully continuous hot mill that they couldn't fully utilize. J&L Steel was smarter because they built a 80" semi-continuous hot mill where they could fully utilize it's capacity. I always thought Tom Graham was a bag of political hot air. Well the fully continuous 84" hot mill across the river that Republic Steel built is still running and Tom Graham's beloved 80" semi-continuous hot mill is gone. So much for Tom Graham's opinion. Oh and didn't J&L Steel go bankrupt shortly after Tom Graham ran off to US Steel? Good job Tom.

Bob Collins: Pat McCon continuous is one pass in each roughing stand. Semi-continuous is multiple passes in a roughing stand; such as our R-2 mill in the old J & L 80" Cleveland.

Brian Olson: Pat McCon Pretty much every hot strip mill built in the 1960s was fully continuous. Some of them had room for expansion where they could install a fifth rougher and/or seventh finishing stand but they were all fully continuous and very expensive to build. J&L Steel was the only major steel company that did not build a fully continuous hot strip mill in the 1960s. J&L Steel went with the poor man's hot mill which was called semi continuous. This design utilized a reversing rougher like the one J&L had in Aliquippa. My understanding is J&L Steel pushed as much steel through that 80" hot mill as they could with that design. The utilization was maxed out. The point TCG was making in the interview was J&L was smart because they installed a mill that was fully utilized. I say J&L was stupid for installed the mill they did because having excess hot rolling capacity allows you to expand in the future like AK Steel Middletown did. It started out making 2.8 million tons. Now it makes 6 million tons. J&L was the first 1960s hot mill to be closed. If J&L had installed the same 84" hot mill that Republic across the river had installed it would have been better off in the long run. J&L always made horrible investment decisions.

Edward Sivak: Pat McCon It started to do trial runs in Nov. of 1964 because they wanted prime coil before the end of the year for tax reasons .

|

| 1 |

|

| 2 |

|

| safe_image for The hot strip mill in Cleveland, OH |

Cleveland Cliffs has bought ArcelorMittal, so I'm saving the entire history page because I'm worried about what CC will do with AM's URLs.

Bob-Dink Heinzman: The video would be tremendously more amazing and entertaining if the editor would put down the mouse in the editing program and let the damn video run....Leave it on one scene long enough to take it all in !!

Richard Allison: I like the video. I don't understand why they flare both stacks with blast furnace gas which could be used to either power a BFG turbine/generating unit that could make at least 250 mw. Flaring that much gas is such a waste.

Richard Allison shared this video

I like the drone shots. I don't understand why both furnaces are flaring all that blast furnace gas when it could be piped to a turbine/generating unit for electricity. That is a lot of BTUs being wasted that could instead bring the cost down to smelting iron. There is a blast furnace plant in Brazil that has turbines that can operate on blast furnace gas. It is a combined cycle generating plant. This plant can supply two turbines to turn two generators, then take the exhaust from the turbines and route it through a hybrid water tube boiler that sends steam to a third generator. The three generators produce over 470 megawatts of electricity. Half of that could power the blast furnaces and BOF. The remaining electric is sent to the Brazil power grid. If the plant had a hot strip, the electric could go there. This plant was owned by ThyssenKrupp and now owned by Gerdau.

Blast furnaces should be looked at as ironmaking and an electric power plant. Japan does the same with some of it's furnaces. Why does the US not do this? This Gerdau plant was constructed by TK and have been generating electric for over a decade. One of these combined cycle plants could almost make an integrated mill independent from commercial power.

|

| Bob Edwards posted Cleveland Republic’s Coke Plant in the winter of 1970. I worked as a lid man and patcher’s helper in the summer of 68&69. These slides were taken from the old Clark Ave bridge. These are batteries 2-4. These replaced an older plant with 1-4. The snowy lot closest to the camera would have been old number 1. Battery 5 is in a separate installation behind these. By products to the left and coal and coke handling to the right. The big conveyor housing moved the coke across the river to the blast furnaces. Several times I was sent in there with a broom and shovel to clean the belt over flow. A real experience to work there as a college kid but so hot, smokey and dangerous. It’s all gone now. The newly created EPA was really down on water pollution. Not so bad about air pollution. Our coke plant in Lorain had closed its by products department in 1966 capturing naphthalene and throwing the rest into the quench water. The water in the gas mains (flush liquor) tended to get very alkaline so we had sulfuric acid added to it. Ammonium nitrate precipitated from this and was sold as bulk fertilizer. They could never get the pH to be neutral. Wherever that quench steam settled served up a double whammy of alternating acid and alkali corrosion. |

Sam Santora posted three photos with the comment: "Universal Slabbing Mill J&L Steel Cleveland Works. Way back in the day!"

Rick Meadows: My father Lawrence Meadows was a foreman there when they rolled the last ingots before the caster and LMF came online.

Pat McCon: Supposedly the slabbing mill roller was the highest paid guy in the mill. It was a blooming mill in Aliquippa, but the same thing.

Richard Jankowski: Pat McCon True That...I was the Youngest Head Roller in The Rouge Steel Slab Mill....1993 I was 43 Years Old...

Graham Whitfield: Yes the Rollerman (as we called them) was the top dog and highest paid. (Quite rightly.)

|

| 1 |

|

| 2 |

|

| 3 |

Steve Koczan posted two photos with the comment: ''This is a sign of Cliffs continued investment in Cleveland's Blast Furnaces. Outer shells of the new stoves being offloaded."

[Several of the comments mention other investments C-C is making to undo the damage done by Mital's minimum maintenance policy.]

|

| Bob Boardman commented on Steve's post Good pics Steve, got these from Ip at Kelly SR |

|

| Bob Boardman commented on Steve's post |

|

| Ron Mamula posted, cropped Here’s the new Stove Shell for C-5. William Malone: Is it a Maxj- stove Ron Mamula: William Malone Danielli-Cours (sp?). 2 new stoves complete and the 3rd with a new barrel section below the dome. Bill McKinney: Ron Mamula when are they supposed to be done? Ron Mamula: Bill McKinney early Summer. It’ll be the last big BF job in Cleveland for many years. Brad Ellis: Brian Strong When is Cleveland supposed to ramp up. Is that true they want 100 bricklayers. Brian Strong: Brad Ellis yeah that’s true will be looking for guys beginning to end of March. Glenn Sloan: Brian Strong ba told me 300 . It was suppose to start in march. brick was infested with some kind of bug they sent them back. this what I heard . Don Weitzman: The last time it was rebuilt was I believe 1984. and c6 was 1986. David Lempke: Don Weitzman C5 Blast furnace was a full relined in 1988 and C6 was done pretty much immediately after C5 in 1989. Both Bailey-Hoogoven design. C6 was again full reline in 2013. With substantial stove work. |

Two of the three photos posted by Brian Bazan with the comment: "C-5 cleveland…. New stoves.."

|

| a |

|

| b, cropped |

Tom Yost provided two photos on Ron's post with the comment: "Thats them coming up the river......"

|

| 1, cropped |

|

| 2, cropped |

|

| John Groves posted Picture is Cleveland No.5 blast furnace, scheduled for a 100-day reline from March 2022 (Viktor Macha image). Cleveland-Cliffs says it might soon replace a blast furnace by EAF steelmaking. In an earnings conference call last week, Cliffs boss said the cost of relining a blast furnace and investing in its iron ore and coke supply chains is now close to the cost of building a new EAF. Cliffs will invest in a 100-day reline of the Cleveland No.5 BF, which is rated at 4350 tons/day, starting in March. The Cleveland No.6 BF (4150 tons/day) will continue to operate during the reline. Cliffs CEO also added comment about the closure of the Mountain State Carbon coke works at Follansbee, announced last week. He said closure will avoid capital expenditures of $400 million over the next few years. Here is the detailed press report of the earnings call published in Steel Market Update ..... CLIFFS CONSIDERS CONVERTING BF TO EAF Cleveland-Cliffs Inc. could join other steel producers in adding electric-arc furnace (EAF) capacity, the company’s top executive said. The Cleveland-based steelmaker is considering that because the cost of relining a blast furnace – and investing in the supply chains needed to feed it – are roughly the same as those for of building a new EAF. Because the costs “come out close to a wash,” Cliffs “might consider an EAF as a replacement to a blast furnace in the future,” Cliffs Chairman, President and CEO Lourenco Goncalves said in an earnings conference call with analysts on Friday, Feb. 11. Goncalves did not have a specific timeline for when Cliffs might add EAF capacity. “Certainly not in 2022. I don’t believe it will be 2023 either,” he said. Cliffs says it is the top supplier of automotive steels in North America, and those products need to come from blast furnace-based steelmaking. But other less-demanding applications could be served well via the EAF route, Goncalves said. While Cliffs is primarily known as an integrated steelmaker, it also operates several EAFs. And sourcing scrap shouldn’t be an issue because of the company’s acquisition last year of Ferrous Processing and Trading Co. (FPT), a leading recycler of the prime scrap needed to make sheet products, he said. Also on the operations side, Cliffs confirmed that it was taking an extended outage on one of two blast furnaces at its Cleveland Works. The work will be on the No. 5 blast furnaces, as SMU previously reported. The 100-day outage will run from March to June, a company spokeswoman told SMU on Friday. That is longer than the 80-90 day outage market participants reported to Steel Market Update earlier this week. We have updated our blast furnace status table to reflect that development. Turning to raw materials, Goncalves said that Cliffs would idle all production at its North Shore mining operations in Silver Bay, Minn., starting in the spring and through at least the fall – and potentially well beyond. He said the company was doing so mostly because of an onerous royalty structure. The extended idling is also possible because Cliffs is melting more scrap and hot-briquetted iron (HBI) in its furnaces – which means it requires less iron ore, Goncalves said. That ability to “stretch” hot metal in addition means that Cliffs needs less coke. And the company is therefore permanently closing its Mountain State Carbon coke plant in Follansbee, W.Va., in the second quarter. Doing so will reduce the company’s carbon footprint and save it approximately $400 million in capital expenditures that would have been necessary there in the future years. Workers there will be offered jobs at other Cliffs operations nearby, he said. Metallurgical coal is heated into coke in coke ovens. Coke is a necessary raw material in steel production via the integrated route - in which iron ore and coke are combined in blast furnaces to produce liquid iron. But that process is also extremely carbon intensive, which is why other steelmakers – Canadian steelmaker Algoma, for example – are building EAFs to replace their integrated operations. By Michael Cowden, Michael@SteelMarketUpdate.com Viktor Macha probably took that picture of Cleveland C5 BF when it was operated by ArcelorMittal. But since 2020 it is owned by Cleveland-Cliffs. Frank Newton: I think its safe to say that Cleveland Cliffs will maintain a few world class B/F's with the money they are putting out but realizes that EAF's need to be built . #7 B/F at Old Inland Steel recently underwent a big reline and upgrade and is using a lot of HBI thus no need for Sinter and a reduced amount of coke and doing very well . Doing good enough that the Sinter Plant is being shut down at Cliffs East ( Inland ) . I think they have a good grasp on the future of steelmaking in North America. Ray Schloss: My fear is that as more and more EAF’s are built, eventually our mills will need more pig iron. As less and less is made here, more and more of it will be imported. Of course for all the, “we’re closing this & that in the fight for fighting climate change,” rhetoric - they will keep buying from Chinese & Indian mills that are Far More Polluting than any of our recently closed ones ever were. Lorain, Zug Island, Ashland. Tom Cobett: Ray Schloss Time to embrace the Hot Briquetted Iron (HBI) made from Direct Reduced Iron made with natural gas instead of coke. Tom Cobett: Steve Sparks Start following the success of the Cleveland Cliffs new DRI plant just outside of Toledo, OH. Their product has the same low tramp elements as pig iron from iron ore. I would not be surprised to see large cordless induction furnaces used instead of EAFs. Frankie Sabo: He also said that EAFs have proven they can’t reach certain grades for all of the automotive needs, you need a blast furnace for that. Brian Olson: Frankie Sabo When SDI Sinton is running full throttle with their degassers then we will know for sure if that is a true statement. |

|

| Karen Cereceres Bates posted Karen Cereceres Bates shared That time they tore down the electric furnace- LTV Cleveland, if I remember correctly. Joe Brown: Was a melter on those electric furnace's. Tapped the last heat ever made on them August 1990. Thomas Flynn: That's part of the bag house still standing. |

%20Steel%20Mill%20Pictorial%20_%20That%20time%20they%20tore%20down%20the%20electric%20furnace-%20LTV%20C.png) |

| Comments on the above share |

|

| Screenshot @ 0:11 of 0:16 [Time-lapse video of charging scrap and molten iron into a BOF.] |

|

| Matthew Pawloski posted Number 2 Steel Producing Cleveland Winter 2014 |

I wonder how much total horsepower these synchronous motors were rated at. This is why power companies would offer lower electric rates to mills that were willing to shutdown during days that had a high electric demand. In the north, these days occurred on hot days. I'm sure the workers did not mind taking off sweltering hot days.

|

| Edward Sivak posted This was 80” Hot Strip Mill LTV Cleveland Circa 1992 |

|

| Gabriel Arroyo posted Pouring Iron in # 2 vessel at #cleveland_cliffs in Cleveland Ohio. While Training the new guy. I was thinking this is a good photo opportunity. Enjoy the photo William E Woods: Which mill was this? I assumed all steel making had left Cleveland? Pat McCon: William E Woods - Heavens no! The Cliffs Cleveland Works (formerly LTV) is going with both BOF shops. There’s no rolling on the west side - just steelmaking. The east side is intact from blast furnaces thru cold rolling and coating. |

If I understand some of the comments correctly, the above photo was on the east side because the J-hook faces the cab. So the following must be on the west side since the J-hook is turned the other way.

|

| Matt Cawley commented on Gabriel's post |

|

| Paul F Clarke shared C5 C6 Cleveland |

|

| Luis Emanuelle commented on Paul's post |

|

| Jeff Picka posted Piping at the Arcelor Mittal steel works, as seen from Independence Rd in Cleveland OH. |

|

| Jeff Picka posted Number Two Steel Producing Facility, Cleveland Works of Cleveland-Cliffs, as seen from Clark Ave in 2018 when it was Arcelor-Mittal. This was built at some point during the J&L years as the Direct Hot Charge Complex, based on comments below. Paul Maier: I’m pretty sure it was built in 1968 by J&L Steel. I spent my college summers in the 80” HSM. Tim Beringer: Paul Maier correct originally J & L [This post has lots of informative comments including some photos.] |

Matt Celeste posted two photos with the comment: "Lake freighter MV American Courage unloads ore pellets near the blast furnaces at the Cleveland-Cliffs Cleveland works at the start of the Labor Day 2022 weekend. At the same time, a Cleveland Works Railway SW1500 pulls a cut of loaded coke hoppers over Independence Road before shoving back towards the furnaces. (9/3/22)"

Blaine Chapman: I put in 34 years at an integrated steel mill in Warren Ohio. 1 blast furnace, 2 BOF’s, a 2 strand caster, hot mill, 2 picklers, galvanize line, cold strip and at one point a silicon line. We were called “The Enigma in the Woods” because our location was 60 miles inland from Ashtabula Harbor and all our ore had to be delivered via rail. 100 car unit train 6 days a week 9 months a year. This was an added cost that most mills didn’t incur, yet we managed to stay operating until 2012 because we filled a lot of small specialty orders like high carbon and various alloys. Eventually numerous bankruptcies, changes of ownership and lack of capital improvements did us in around the the time the government was bailing out General Motors all the while turning a blind eye to the steel industry.

|

| 1 |

|

| 2 |

Matt Celeste posted two photos with the comment: "MV American Courage unloading ore pellets at the Cleveland-Cliffs blast furnaces in Cleveland. (12/2/22)"

Jim Peyatt: Look at them new blue stoves Boilermakers 744

Fred Mayo: Anyone know how many blast furnaces are there left active in the US?

James Torgeson: Fred Mayo 16, which includes several that are marked as idle by their owners.

John Groves: James Torgeson As James says, there are only 16 blast furnaces remaining in USA, 8 owned by Clevelend-Cliffs and 8 by US Steel.

Cliffs has one furnace each at Middletown, Dearborn and Indiana Harbor East, and two each at Burns Harbor and Cleveland. No.4 furnace at Indiana Harbor West plant was recently taken out of operation and may be listed as held in idle reserve, but it is unlikely ever to operate again.

US Steel has four furnaces at Gary, two at Mon Valley and two at Granite City.

Dan Kleinhenz: Do they eventually go to rail shipments once the lake freezes over or do they stockpile materials to get them through?

Dru Joslin: Dan Kleinhenz we beat the ice up. [I don't understand this answer because the Soo Locks close between Jan and Mar.]

|

| 1 |

|

| 2 |

|

| Chris Whitney commented on Matt's post I got to go up on the ore bridge a few years ago. That was a cool experience. |

Lance Aerial Media posted three photos with the comment: "Cleveland Cliffs Steel Mill and the 700’ Dorothy Ann / Pathfinder Tug Barge."

Dennis DeBruler shared

|

| 1 |

|

| 2 |

|

| 3 |

Six of 44 photos posted by Robert W. Laeng with the comment: "Some photos from steel, through the years. Pre-Cliffs, some from LTV days."

|

| a |

|

| b |

|

| c |

|

| d |

|

| 3 |

|

| f Matthew Mrzlock: What Hotmill are those edger drive shafts from?? Robert W. Laeng: Cleveland 84” |

Is this the 84" mill that Robert references in the above comment?

|

| Bob Clementi posted LTV Cleveland 84 tandem mill David Dawson: Cold mill. Been there a couple times lol Diane Scott: I worked in the roll shop next to it when it was Republic Steel blue. Justin Marsh: It’s painted blue and green now, Cleveland Cliffs colors. I’d get a picture but I’m not in that department anymore. |

|

| Propped Productions posted This stretch of Cleveland’s industrial valley has carried the weight of molten metal and manufacturing for over a century. And tucked just off the Cuyahoga River is one of the city’s more quietly significant structures: Steel Production #1 Caster. It’s not the flashiest part of the skyline, but this building has churned through generations of industry — from the days of Corrigan-McKinney, through Republic and LTV, then ArcelorMittal, and now Cleveland-Cliffs. That smoke you see? It’s not the past — it’s the present. Production hasn’t stopped. This part of the valley still hums. The caster itself plays a specific role: turning molten steel into solid slabs that move downstream into coil, plate, and other forms. And while most of what happens here is out of sight to the city above, it’s a reminder that some parts of Cleveland’s legacy never left — they just kept working. This isn't a relic. It’s an active chapter in Cleveland’s industrial story. Propped Productions shared Cleveland's backbone Dennis Beno: The two stacks you plainly see are the stacks for the vessels (#1 & #2) of #1 Steel Producing (aka: The East Side, The Republic Side). So at the time of this picture, it looks like they’re not casting. The smaller, tan building almost out of the pic to the right of those stacks is the VCP/LMF and to the right of that (the blue/grey building) is the Continuous Caster. |

2 of 15 photos posted by Bubba Dubs with the comment:

Cliffs steel, Cleveland Ohio. The American Courage runs the iron ore shuttle from the head of the Cuyahoga river to the Cliffs steel mill at the end of navigable water.

1000ft lakers bring iron ore from the deposits where their mind and unload at the pellet terminal on Whiskey Island. This is the same place where the Hullet unloaders used to roam. Then the ore is loaded on a smaller “River class” vessel like the American Courage to be shipped up river. Here are some shots of the action from the pellet terminal, and elsewhere up there river.

|

| a |

|

| b |

Owen Nesslage posted nine photos with the comment: "Took a small detour on a road trip to Cleveland to explore the industrial valley. A truly unique area to witness mill operations, and a special thanks to the friendly faces down there who weren't bothered by my presence with a camera!"

[Some comments discuss the ownership of the CROW (Cleveland Works Railway).]

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 [The W&LE Bridge] |

|

| Bubba Dubs commented on Owen's second photo |

|

| Dennis DeBruler commented on Owen's third photo Google's Street View caught bottle cars in this scene. Oct 2022 https://goo.gl/maps/NdNHycR6nYjMnSVs6 |

|

| Dennis DeBruler commented on Owen's fourth photo The Street View car had to stop and wait for the bottles to go by. Oct 2022 https://goo.gl/maps/NDz9rnvC9CZWnVSM8 |

|

| Dennis DeBruler commented on Owen's first photo I had trouble finding this view, but I was motivated because of the blast furnace in the background. I also caught the control tower for the former-W&LE bridge. Oct 2022 https://goo.gl/maps/J2Tp9NFR1z1MDp3o8 |

Bruce Takach posted two photos and a comment indicates they are from this plant.

|

| 1 Locomotive Trails posted Republic Steel Corp. (River Terminal Ry.) SW7 No. 98 switches molten steel in the Cleveland, Ohio steel mill. This mill along the Cuyahoga River, which was known for burning in this era, was merged with Jones & Laughlin Steel, located across the river, in 1984 to become part of LTV Steel Corp. Stephen Wolstenholme shared LIVE GAME CS posted Republic Steel Corp. (River Terminal Ry.) SW7 No. 98 switches molten steel in the Cleveland, Ohio steel mill. This mill along the Cuyahoga River, which was known for burning in this era, was merged with Jones & Laughlin Steel, located across the river, in 1984 to become part of LTV Steel Corp. September, 1981. Photo Credit to Bill Edgar. D Eric Davis shared Craig Cloud: LTV=Ling-Tampico-Vought was large conglomerate acquired J&L Steel making it part of company. After LTV itself dissolved the steel business unit stayed in existence as LTV Steel! |

|

| 2 |

|

| Fred Bultman posted Republic Steel Cleveland in about 1960. The air is very smoggy. This is Arcelor Mittal now. James Torgeson shared Republic Steel in Cleveland. |

Anonymous participant posted two photos with the comment: "Former local 17 Ironworker, Cleveland Ohio. Pictures from a couple of many days spent at what is now Cleveland Cliffs."

Theresa Rice: Tommy Herdman first pic is bottle pouring station second pic is west end of c6.

Michael Wozny: Good ole East side BOF!! Love it down there!

|

| 1 |

|

| 2 |

Sam Foster posted two photos with the comment: "I recently edited up this drone photo from February of this year. It shows some torpedos being brought to the small interchange yard west of the canal at Cleveland Cliffs Indiana Harbor. The old ISG sinter plant in the background was demolished a few months ago. I included a photo from where it used to stand. Taken today. Full res image: https://flic.kr/p/2p14bRu."

Bruce Takach: You called them torpedos cleveland west side ( CV) called them subs and Cleveland’s east side (RT) called them bottles.

|

| 1 |

|

| 2 |

Austin Corlett posted three photos with the comment: "J&L 80" Hot Strip Mill's Motor Room. 1964, 1993, 2023."

Alan Murray: Yep, I recognize the 80” HSM motor room at the West Side Cleveland - I was the Safety Engineer for that mill in the early 70’s.

Paul Maier: As a lowly summer help, I was not allowed in there. Anyone have any pictures of the mill side?

|

| 1, cropped |

|

| 2 |

|

| 3 |

Nick Wondolowski posted nine photos with the comment:

Cleveland cliffsCleveland Ohio 2022310 strong💪🏼

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

Tony Kathy Kaliszewski Sr. posted 14 photos with the comment: "As promised...Here are the pics from the 2018 USW 979 Cleveland Calendar. The theme was the process from start to finish in 14 shots."

At 18 years of age, first real Summer job was as a “lid-man” at the open coke battery at Republic Steel in Cleveland in 1969.I brought a camera in my lunch bucket to document the experience. I spent two Summers there which greatly helped pay for my college - it also made me realize I wanted to go to medical school 😉.

Glenn Mclaren: Thanks for sharing..I worked those same batteries in the mid-70s...It's hard to understand the totality and surrealism of this environment unless you actually experienced it..

Bill Schultz: Glenn Mclaren Yes - as you know it was not permitted to film but I couldn’t let the experience go - if only to confirm that I did it.

Bill Schultz shared with the comment: "A post I made in Steel Mill Pictorial about my first job at 18 on the Republic Steel Cleveland Coke Plant in 1969."

Gordon Kocher: Worst job in the steel mill!…

|

| Bob Edwards commented on Bill's post Here’s a photo of batteries 2-4 with number five in the distance. They made up plant #1 taken from the Clark Ave bridge. |

|

| Christian Thomas posted Here's a short video of the Cleveland Cliffs facility at Burns Harbor, Indiana. If you look closely, you can see the Wilfred Sykes in Lake Michigan. |

|

| Bryan Burton Photography posted Overlooking the blast furnace at “The Crow” (Cleveland Steel Mill). What happens when you go to shoot steam in the valley and two of the three runs are cancelled due to flooding. 04/2025 Special thanks to my tour guide for the weekend, Coal & Steel Railroad Photography. |

|

| Interlake Steamship Company posted 0:09 video Cool view of iron ore flowing into the belly of our M/V Mark W. Barker, loading at Cleveland Bulk Terminal earlier today. It really showcases the unique square-shaped cargo hold design on the 639-foot [195m] vessel, the newest and most versatile on the Great Lakes! 🎥: Eric Helder [1000' Lakers bring the ore to the dock from Lake Superior and then the short Mark W. Baker takes the ore up the river to steel mill.] |

|

| Facebook Reel |

The reel's screenshot is looking over this area. The drone is too far north to catch the blast furnaces. The roundhouse in the upper-left corner was the B&O Roundhouse.

|

| Satellite |

Propped Productions posted three photos with the comment:

Three looks across Cleveland-Cliffs’ Cleveland Works, the integrated steel plant that anchors the Industrial Valley along the Cuyahoga River. The river’s northbound bend, the stockyards, and the skyline line up here because this corridor was designed around ore on lake freighters, coal on rail, and water access—industry first, then cityIn the foreground: the steelmaking core that turns hot metal into steel—blast furnaces feed the basic oxygen furnace (BOF) shop, which casts slabs for the rolling side of the plant. The long shed stretching toward the river is the 84-inch hot strip mill, where those slabs are reheated and rolled down into hot-rolled sheet coil for autos, appliances, and construction. Utility trestles crossing the yard carry gas, steam, power, and process water between unitsThat elevated highline conveyor marches over black coke stockpiles—the fuel and reducing agent for the blast furnace. Below are stock pads and rail spurs; above them the Cuyahoga provides a protected channel so lake boats can work the docks. This is why the plant sits here: materials in by water and rail, finished steel out the same wayOn the west bank: piles, conveyors, and the furnace bay; on the east bank: yards and the long roll-shop sheds. This is one of the few U.S. integrated mills still operating—a site that evolved from Republic Steel through LTV and ISG to ArcelorMittal, and since 2020 part of Cleveland-Cliffs. The mill helped build Cleveland’s skyline and supplied steel across the country—and it’s still producing today.

|

| 1 |

|

| 2 |

|

| 3 |

Bubba Dubs posted six drone shots of blast furnaces #5 and #6. And the comments had a bunch of other photos of the plant. They also mentioned that #7 is going to have a 180 day reline.

Jamie Lauderdale: The filthiest slabs I ever get at my mill. Yet the Korean ones come in absolutely pristine. [Subsequent comments point to the problem being the shipping, not the production. And it is plates from a different C-C mill. This mill produces coils.]

A 28:32 video showing LTV operations when they still used ingots and a slab mill instead of continuous casting. Jim Votruba commented on a post that he made the video in 1989.

32 drone photos of cranes doing upgrades of blast furnaces replacing hot stoves

24 drone photos A share by Alan Eozanski has a 1:11 closeup video of a bottle train in a comment by

Dane Rübsam.

21 drone photos a some comments help identify some of the buildings

No comments:

Post a Comment