(

Satellite)

I didn't even know that Kansas had coal until I started researching Big Brutus, the world's largest surviving electric shovel. This shovel has been preserved as

a museum. They also display some smaller equipment to provide scale and some more history.

Big Brutus stripped overburden from 1963 until 1974 when the economical coal reserves became exhausted. [

KansasSampler] 150 railroad cars were used to ship the 11,000,000 pound shovel from the Bucyrus-Erie plant in Milwaukee. Strip mining coal in southeastern Kansas began in the 1870s and became the preferred method by the 1930s. 300 million tons of coal were removed from the area. [

kshs]

Big Brutus wasn’t always the biggest shovel—its mightier “sister” Big Bertha was dismantled, and the largest electric shovel on earth, the 22 million pound “Captain”, was scrapped in 1992, leaving Brutus to hold the lonely title. In the 60’s and 70’s, when the mining giants were in their heyday, Big Brutus’ bucket could lift 150 tons of coal, and worked at a speed of 0.22 MPH, 24 hours a day, using as much electricity as a town of 15,000 people. [AtlasObscura]

It was the second largest operating shovel when it started work in May 1963. [

asme]

|

asme, p2

|

It had a maximum stripping depth of 69' but the 18-24 inch coal seams that it exposed were just 20' to 50' below the surface. It used 7,200 volts and up to 1,200 amps. (8.64mw = 11,586 horsepower. Two of its electric motors were 3,500 horsepower each.) During its decade of operation, the $6,500,000 machine exposed 9,000,000 tons of coal. "Standing 160 feet high, weighing 5,500 tons, and moving

at speeds up two-tenths of a mile per hour, the machine

stripped about a square mile per year. The bucket scooped

out 90 cubic yards or 135 tons of earth with each bite." [asme] Most articles quote the "heaping" capacity of 150 tons.

|

Merike Joosep posted

Big Brutus is the world's largest electric shovel. It stands 16 stories high and weighs 11 million pounds — that's 5,500 tons. He's painted bright orange and once had the job of scooping rock and dirt off the coal seam in a strip mine. Each of its bucket loads could fill three railroad cars.

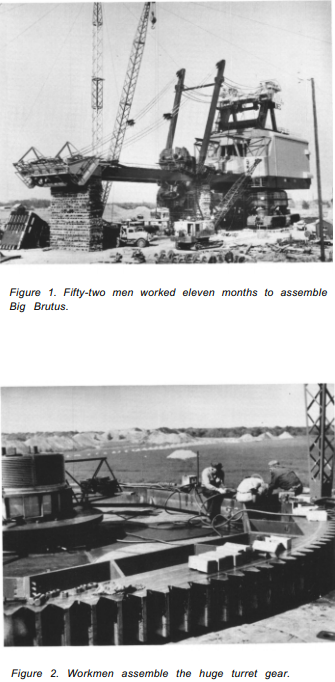

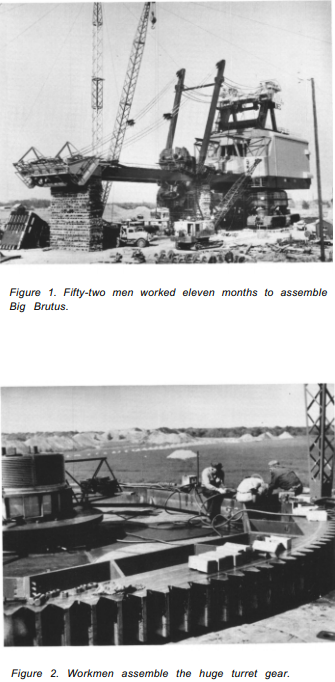

It took 52 men about 11 months to assemble it in 1962, cost - $6.5 million. Big Brutus worked 24 hours a day for 11 years. When the Pittsburg & Midway coal mine shut down in 1974, Big Brutus was turned into a museum.

Linda Chamberlain shared

Jeff Shown: I’ve been there several times. Used to be able to walk to the top of the boom when I was a child. Last 2 times (19 & 14 years ago) they didn’t allowed access onto the boom. You can see it for 10-15 miles before you get there if there’s a break in the trees. Cool place. Kansas breed & raised myself.

Jeff Shown: https://www.bigbrutus.org/about.html

Dirty Machines posted

Dirty Machines [Another Facebook group that doesn't properly acknowledge the source of their material.] |

Two photos by Mike Isakson via

KansasSampler.

|

| 1 |

|

| 2 |

|

Dirty Machines posted

Dirty Machines posted

James Mooney: I've been there and it's really impressive in person. 90 yd bucket. |

This is a different view. It clearly shows the dual crawlers at each corner of the frame.

The Page 222 dragline that ran on rails was donated by the Wilkinson family. They bought it in 1938. [

joplinglobe via

Dennis DeBruler] The Page dragline would be the white "house."

Once again, a road map allows us to see the land scars or

tattoos of strip mining.

You used to be able to climb up the boom for a spectacular view of the countryside. [comments on a

post]

This

post has a video of it in operation.

I was an engineer at that mine in the early 70's the center pin had a two person elevator in it. My memory is that it had a 90 yard bucket. It was all electric with an MG set and ran 24 hours 7 days a week.

There is more than one Brutus.

|

Tim Swaren posted

I was out at the Paintearth Mine Feb. 4 and drove past Brutus. Not much happening with it. I was recently talking to someone who worked there and they told me there has been some electric motors removed from the house. Also not long ago, they caught some idiot trying to get in to steal some electrical cables for the copper. That doesn't surprise me.

Sherman Shedd: Marion , probably about a 8200. |

|

Machinery Planet posted

‘Big Brutus’ strip-mining shovel in southeast Kansas

[Note the guy standing in the middle of the catwalk.]

Greg Smith: Awesome machine has a very cool museum with all kinds of mining equipment. They will let you go up in the machines. Its very impressive. 10$ well spent.

James Clements: I’m from southern Indiana and we were surrounded by these behemoths like the 6360 captain. Peabodys 5900 several 5760s and the biggest marion drag-line working side by side with the second biggest bucyrus drag-line. Wish they could have saved a few of them. forgone times. |

Eight photos I found in the comments on the Machinery Planet

post.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

8

[They no longer let you climb up the boom.] |

William Oldani

posed six photos with the comment: "I did not realize this, but when Brutus was built in 1962 they did not have a specialized ventilation room on board for it. as you can see in the photos the original machine was missing the ventilation house but the machine that is the Brutus Museum has the ventilation house on it."

Matt Weyand: Never noticed that before that it didn’t have any filter housings

William Oldani: Matt Weyand actually neither did I until this morning when I was looking through my books and realized there was a difference in the two machines!

I would guess that when the first machines came out ventilation was not one of their biggest issues as we see in a lot of machines, the extra ventilation was added in the latter 60s.

David Kimrey: Matt Weyand It was constructed with exhaust fans in the back of the machine but we had problems with dirt and dust entering the front of the house. B.E. built intake fans and filters for the front, I think they were installed in 65. They eliminated the dirt, the house could be pressurized with clean air and the exhaust fans removed most of the heat.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

Jack Pippenger

posted three photos with the comment:

Hi all. Saw Big Brutus last weekend with my brother. Loved the museum and well worth a visit for anyone in or near southeastern Kansas interested in super stripping shovel history. Adding a couple pics here of Brutus.

One question. While there, staff said they were researching the largest shovels to see where Brutus fit. They found names for the 6360, 2 x 1950B, 2 x 3850B and 5960) but could not find anything on the 5900. I thought there was only one but found there were two (0ne at Peabody Lynnville and one at AMAX Leahy). Found some information on both but not their names. Does anyone here know the names of the 2 x 5900s?

Matt Weyand: I don’t believe they had names like the other stripping shovels, like the Captain, Brutus, Big Hog, Mountaineer, etc. I believe these two were only known by their model numbers, 5900. I don’t recall ever seeing names for them.

David Rocketflute: Don’t think the one at Leahy had a name everyone just called it the 5900 think it was the last super stripper built. Would set in school and watch it work stripping.

Jack Pippenger: David Rocketflute my research said it was the last Super. All big draglines after that. Started at Leahy and finished at Captain.

|

| 1, cropped |

|

| 2 |

|

| 3, cropped |

|

Big Machine posted

Awesome.! Big Brutus from the top.😍

Cr: Jacqueline |

|

Piers Austin commented on the above post

Was there two months ago! |

Horsepowers

posted four photos with the comment:

In this video I am in Southeast Kansas and take a Tour of Big Brutus and the coal strip mine where this giant machine worked 24 hours a day 7 days a week from 1963 to 1974. This machine was an electric drive electric shovel that stands around 160 feet tall and had a working weight of around 11,000,000 pounds.

Mike Less - Farmhand Mike

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

This map is one of the exhibits in their museum building. I didn't know that Michigan also had coal.

|

| Information about Big Brutus starts here |

%20Facebook.png)

No comments:

Post a Comment