|

| HAER PA,65-MONE,1- UPSTREAM VIEW OF KOPPERS COKE PLANT IN FOREGROUND. BLAST FURNACES & OPEN HEARTH BEHIND. VIEW LOOKING WEST. - Pittsburgh Steel Company, Monessen Works, Donner Avenue, Monessen, Westmoreland County, PA Photos from Survey HAER PA-253 |

|

| HAER PA,65-MONE,1- AERIAL VIEW OF BLAST FURNACE PLANT. COKE PLANT & CITY OF MONESSEN IN BACKGROUND. VIEW FACING SOUTHEAST. |

|

| HAER PA,65-MONE,1- AERIAL VIEW LOOKING SOUTH, JANE FURNACE IN CENTER. COKE PLANT ON LEFT, BLAST FURNACE NO.S 1 & 2 ON RIGHT. |

|

| HAER PA,65-MONE,1B--3 EXTERIOR VIEW, NO. 3 BLAST FURNACE CLOSE-UP. William David posted Rob Lucas: That's No.3 Bast Furnace. "Jane" |

Significance: One of several large steel making complexes in the Monongahela River Valley in southwestern Pennsylvania, the Pittsburgh Steel Company's Monessen Works grew from a rod and wire mill to a fully integrated steel making facility with its own coke operations, open hearth furnaces, blast furnaces, blooming and billet mills and, most recently, continuous bloom caster. The firm has been a major manufacturer of seamless tubing. [HAER-data]

|

| HistoricPittsburgh, cropped [The coke plant is in the background.] [post-gazette gives a founding date of 1889 but this page says the coke plant was built 1941-42.] "The Pittsburgh Steel Company’s Monessen Coke Plant was built in 1941-1942 to provide aid to the United States during World War II. The plant was located on the site of the American Zinc & Tin and Carnegie Illinois Steel Corporation facilities. In order to construct the massive facility, a river wall had to be built to ensure enough ground would be available to construct the plant. The Pittsburgh Steel Company employed over 300 people to construct the wall by hand. During this period the Pittsburgh Steel Company manufactured numerous products including billets, wire, wire-fence staples, poultry-netting staples, and steel wire nails. The plant originally operated with 74 underjet ovens. In 1995 Koppers bought the site and remodeled the plant, saving it from total abandonment. In 2004 Koppers operated 57 ovens, producing approximately 360,000 tons of coke per year." Jackson-Township historical preservation posted Aerial view of the Pittsburgh Steel Company mills along the Monongahela River at Monessen, Westmoreland County in 1954. The Pittsburgh Steel Company’s Monessen Coke Plant was built in 1941-1942 to provide aid to the United States during World War II. The plant was located on the site of the American Zinc & Tin and Carnegie Illinois Steel Corporation facilities. In order to construct the massive facility, a river wall had to be built to ensure enough ground would be available to construct the plant. The Pittsburgh Steel Company employed over 300 people to construct the wall by hand. During this period the Pittsburgh Steel Company manufactured numerous products including billets, wire, wire-fence staples, poultry-netting staples, and steel wire nails. The plant originally operated with 74 underjet ovens. In 1995 Koppers bought the site and remodeled the plant, saving it from total abandonment. In 2004 Koppers operated 57 ovens, producing approximately 360,000 tons of coke per year. (Photo from https://historicpittsburgh.org/) Arthur Godfrey shared For those of you that might have worked there. Nicholas Luptak: Work there now for Cliffs. |

|

| Nick Smerilli posted Picture from the 70’s of Monessen Wheeling Pittsburgh steel on fire. https://archive.triblive.com/news/one-of-regions-worst-blazes-put-firemen-to-the-test-in-76/ Jason Lhota: Wasn’t that Page Wire? Something like that? Thomas McGee: This was Pages and yes we made rails also we had a trial run on angles |

|

| Frank Jacobs III posted Monessen Pa [Note the Donora Monessen Bridge in the left background.] |

|

| Emilly Rose posted Steel mill monenssen |

|

| Frank Jacobs III posted From the 1961 Monessen High School yearbook. Evan T Williams II: Was that the mill used at the end of the movie Robocop? Frank Jacobs III: Evan T Williams II yes. |

|

| Frank Jacobs III posted Monessen, Pa long ago. Thomas Crespo: #3 Furnace on the right so pic is very late 1940s or 1950s. Kevin Gladysz: Thomas Crespo #3 :"Jane" furnace. Named after Jane Maxwell, wife of the President of Pittsburgh Steel. To the left are #1 and #2 furnaces. |

|

| Frank Jacobs III posted I was a kid near Monessen in the 50's. |

|

| Frank Jacobs III posted Pittsburgh Steel Monessen. |

|

| Frank Jacobs III posted Tin mill in Monessen, Pa. Donald Legg: I did not know they had a tin mill in Monessen, Brian Filardi: Donald Legg Yep the tin mill was Monessen's very first industry |

|

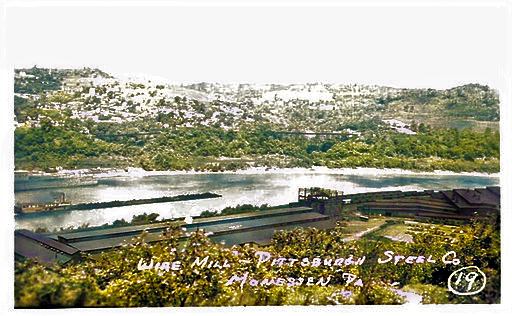

| Frank Jacobs III posted Nice postcard. |

|

| Frank Jacobs III posted Monessen, Pa. |

|

| historic-structures "This large steel works is located at a bend in the Monongahela River, about forty miles by river from Pittsburgh. The works encompasses nearly 300 acres and extends more than two miles along the riverfront in Monessen. It includes fifty-six Koppers underjet-type by-product coke ovens, three blast furnaces, a basic-oxygen process shop, a five-strand bloom caster, a universal rail and structural rolling mill, shop facilities, and offices. Among the defunct operations are the blooming, billet, and bar mills, the rod mills, and the wire mills." This reference has four pages of history and seven pages of pictures. The following caught my eye. "Yet another advantage of the Monessen site, which it shared with other Pittsburgh area locations, was that it was situated within the Pittsburgh freight zone. This had important ramifications for the marketing of steel products. Since about 1898, and particularly after the formation of U.S. Steel in 1901, steel producers across the country had adopted a pricing system known as Pittsburgh Plus. Originating as a pooling arrangement to stabilize the industry and end the cut-throat competition that plagued the industry during the early 1890s, Pittsburgh Plus pricing meant that the delivered price of any steel product, regardless of its point of origin, was identical to that set by Pittsburgh District producers (usually U.S. Steel). For example, when Chicago steel mills sold to Chicago consumers, they were obligated to charge the same price as Pittsburgh mills: a charge which included a standardized freight charge from Pittsburgh to Chicago. The Chicago steel maker realized an added profit in so called phantom freight, but was unable to undercut Pittsburgh producers. This system protected Pittsburgh from competition and spurred the growth of the region. It remained an asset until the World War I period, when the growth of the western market, the rising cost of transport and increased phantom freight, along with cheaper production costs, allowed western producers to increase their share of the market." And: "Dormer's tin plate company was incorporated as the National Tin Plate Company in 1898 and began shipments in May of that year. The company developed an innovative production method known as the Monessen system, based on nonunion labor. An invention of Donner, who patented it in 1898, the Monessen system substantially reduced the amount of handling necessary to produce plate. Rather than men called 'rollers' passing the plate through the rolls manually, each stand of rolls was connected in tandem so that a sheet going through the first roll was fed automatically into the others. As the Iron Trade Review described it, this 'system of working' was different from the 'regular style' since it allowed each stand of rolls, as well as each set of workman, to be dedicated to a certain product. The Monessen system resulted in a larger production and less breakage of the plate. It also reduced the number of workmen necessary in production. Such a system could have emerged only under nonunion conditions, since the Amalgamated with its rigid work rules refused to permit such innovations." [I have been trying to find information on the history of rolling mills. There is also information on open hearths and blast furnaces.] "The electric, traveling overhead crane was developed in the 1880s and had become standard equipment at most steel plants by 1900. The crane greatly facilitated materials handling, making large-volume steel production possible." Rob Lucas posted, and again Monessen, Pa. |

Anthony Cominotti posted nine photos.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| Chris Foor posted Picked up this pic today. I'm thinking it's the saw cutting the rail at the monessen rail mill wheeling pittsburgh had.😁 |

%20Steel%20Mill%20Pictorial%20_%20Picked%20up%20this%20pic%20today%20_%20Facebook.png) |

| Comments on Chris' post |

Rick Arnold posted three photos with the comment: "Coke plant in Monessen, Pennsylvania."

Adam Burke: I’ve been employed there for 15 years. The batteries are on hot idle at the moment because of the scamdemic. We’re going to be firing up in the next 2 months or so. I’ve been there through koppers,, arcelor mittal.,and now Cleveland cliffs. I’m praying I can retire from there.

Kim McGavitt: My dad worked Monessen from 1968 till the bankruptcy in 1985. He transferred to an Ohio location and back to monessen when Koppers took over. He retired in 2003.

|

| 1 |

|

| 2 |

|

| 3 |

|

| Rich Pantaleo commented on Rick's post Nice shots Rick! Here's the same plant back in 1965, photo from the Pittsburgh Steel Company collection, courtesy of the Greater Monessen Historical Society |

|

| Rich commented on his post I took this in June of 2019. This day I lifted the drone off and they immediately shut the stacks down. I was able to get a pic first. hahahah David Wheatley: I was at exxon the day this happened. Those are actually flare stacks. A safety device to what i am told when there is to much back pressure in the coke of gas mains. Rick Arnold: Rumor had it they thought the drone was from the EPA hahaha Butch Fike: Rick Arnold. Unlikely. I know the EPA , Allegheny Co. & the mills themselves hired smoke watchers for these mills in the Valley. Knew a buddy that did that 30 years ago - long before drones. They know what's going on & don't need flying devices. AC Brown: David Wheatley correct, if suction is lost the flare stacks are ignited to relieve excess pressure. Most often due to an equipment malfunction or failure. Most likely were testing the equipment. David Wheatley: AC Brown if my memory is correct they had a issue this day. I was at a bus stop picking up my wife and was there for like 15 mins and they was going off before and after i left. I know in my plant they test them once a week and they only do one main at a time. AC Brown: David Wheatley could be, I worked there years ago & we were having issues with the exhauster failing due to bearing problems. David Wheatley: AC Brown i have only seen this happen once in my 10 years in clairton. We had a total of 5 batteries flare at once. I was lidding and the oven we was about to charge the stack was right by it. I think i pooped my pants when i steamed up and then bam the stack went off. But there was a issue in the control room that night. AC Brown: David Wheatley lol, topside would be scary if that happened. Clairton is where I'm at now. David Wheatley: AC Brown it def was and i am in clairton as well, i was on a double when that happened. Robert King: Is it me or is this battery very small? Our battery had 76 ovens, but looks like crap compared to this one. Rich Wilson: First department I was assigned to when I first started with Wheeling-Pitt in the late seventies. The only facility remaining at that plant. |

|

| post-gazette, Alexandra Wimley/Post-Gazette, first of ten photos [This is probably the byproducts processing part of the plant.] "The 45-acre plant in Monessen -— equipped with 56 ovens that can each hold 12.5 tons of coke — is essentially a middleman carrying out the work necessary to keep steel mills going. This plant has seen a revolving door of owners — Wheeling-Pittsburgh Steel, Sharon Steel, Koppers among them — as the industry has struggled. It also has been cited for environmental violations and workplace hazards that come with baking coal and removing impurities like coal tar, sulfur, liquid ammonium sulfate and oil." AM invested $2m in upgrades in 2018. The plant employed 180 people in 2019. [Much of the article discusses pollution and safety issues.] |

|

| Rick Arnold posted Two flames Cleveland Cliffs Monessen Coke Plant. Robert Sum: Was this a Wheeling-Pitt plant at one time? Scott Gantner: Robert Sum wheeling Pitt steel was across the river in a town called allenport....this place used to be called koppers and then ArcelorMittal. Robert Sum: Scott Gantner I did some service work for Wheeling Pitt Allenport in the early ‘90’s. I thought they also had a plant in monesson. John Slowikowski: Robert Sum yes both the Follansbee and monessen coke plants fell under wheeling-pitt’s umbrella. Nate Nowak: Wheeling Pitt had an integrated mill at Monessen at one time. [I'm not the only one that has a hard time figuring out which mill was on which bend of which river in Pennsylvania.] Randy Danielson: A 10 and a 16" bleeder stack if I recall correctly. |

|

| Fort Frick Photography posted The Cleveland Cliffs Monessen Coke Plant at sunrise. Prints: www.fortfrickphotography.com [The white emissions is mostly steam, that is, water.] |

.jpg) |

| Fort Frick Photography posted Another one from Monessen. |

Bill Brown posted four images with the comment: "WPS Monessen Plant coke battery as it operates today under Cleveland Cliffs. Only remaining operating part of the plant left. After bankruptcy, Sharon Steel purchased it in 1988, sold to Koppers in 1995 & renovated, sold to ArcelorMittal in 2008. June 2020 Arcelor put it on hot Idle. Cliffs acquired in September 2020 & restarted in 2021. Currently there are 2 batteries with 56 ovens with a capacity of 327,000 tonnes of coke per year."

Jeffrey Mauk: That’s a clean looking Coke Plant. Looks like the colors for the Pittsburgh Steelers.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

AM did a $50m upgrade in 2014. [graycor]

Herald-Standard, Jun 3, 2021: coke plant to recall workers

No comments:

Post a Comment