I learned of this mine because its Marion 5900 stripper shovel replaced the Marion 6360 in the Captain Mine when the 6360 burned in 1991. I see from the directory below that this mine had just recently closed at the time of the fire.

|

| Michael Davis enhanced a photo posted by Kevin Bridle of the 5900 after it was moved to the Captain Mine. Kevin provided several more photos of the 5900 |

|

| Add caption |

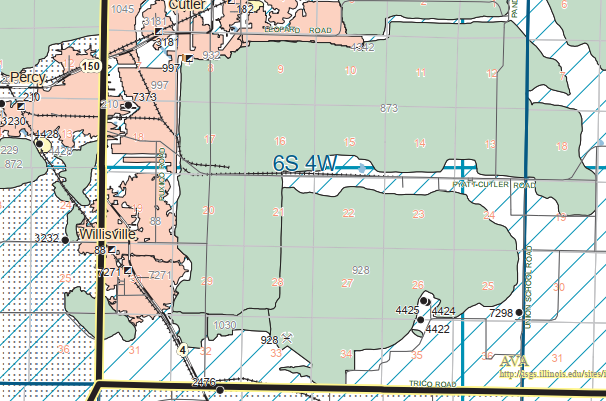

Fortunately, I still have the map extract in my Download Folder from writing the notes on the Captain Mine because it applies to this mine as well.

This mine is why I outlined the Captain Mine on a satellite image. It was basically the land tattoos in this area that were not part of the Captain Mine.

It is good that they marked the tipple for this mine because it is not obvious how it got rail service because I couldn't find a spur on any topo maps. But the 2005 SPV Map shows a spur to the Amex Mine, which the directory indicates was one of the owners of this mine. Using a 1981 aerial photo, I found the spur off the GM&O/M&O railroad. Not only is the spur now abandoned, so is the railroad.

|

| Map |

|

| Satellite plus Paint |

|

| Satellite plus Paint |

|

| PAmining posted Here’s a throwback flyover from 1984 featuring the last stripping shovel ever built! This Marion 5900 was sold to the AMAX Coal Company in southern Illinois in 1971. This machine was equipped with a 210 foot boom, and a 105 cubic yard variable pitch bucket, which allowed for a greater cleanup radius. This variable pitch bucket helped the shovel to uncover two different coal seams simultaneously. As you can see in the photo, the shovel is uncovering the coal seam its sitting on, while also uncovering a shallower coal seam in the direction of mining. This machine later worked at the Captain Mine, where it was repainted in their blue and white color scheme. The last stripping shovel ever produced would eventually take over for the largest stripping shovel ever produced, The Marion 6360 “Captain”, when a fire retired the Captain in 1991. Paul Dhanjal: That’s neat, I had no idea they could do that, two different elevations at the same time or does he/she dig the lower elevation first then step back and cut the upper elevation. PAmining: Paul Dhanjal I’m pretty sure they just dug both from where they sat, then advanced and repeat! The variable pitch bucket is what made it easier for this machine. (I think they stripped 2 seams with a lot of other stripping shovels as well, just not as efficiently) but this variable pitch bucket was hydraulically adjustable from the cab, but worked off of the weight/pressure from the dipper handle so you could essentially dig with the bucket flat all of the time! Where as previous machines had fixed buckets on the dipper handle which cut down on the cleaning range of the machine! John Bell: PAmining it has knee action that what made it possible to dig at different levels. PAmining: John Bell many Marion shovels had knee action and only worked one seam. Tom Hulting: Where was this in Illinois? Chris Greider: Cutler |

|

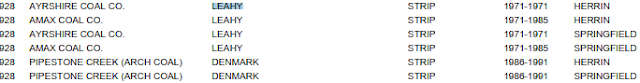

| Dennis DeBruler commented on Tom's comment Given Chris' answer, I found index 928 was the AMAX owned mine and index 873 was the Captain Mine to which the shovel moved in 1991. |

|

| James R Griffin Sr. posted Amax Leahy Mine 5561 in 1984. Brooks Walters: Wrong Leahy Mine never had a 5561. They had a 5900 shovel and 7500 dragline. William Oldani: Brooks Walters sorry Brooks, but Leahy Purchased the 5561 from Captain in the Late 70’s after the P&H 5700 went on Line. Captain used it on and off in both the 6360 pit and the 2570 pit as a Parting Machine. It was to slow and Always in the Way for the Main Excavators. They ( Captain ) parked it, and eventually sold it to Leahy. In 1986 it was torn down at Leahy, which was under the new name of Denmark. Brooks Walters: Hired in at Leahy Mine in April 77. Transferred to Wright mine in 78. Paneled to Ayrshire mine in 1980. Must have missed them purchasing a 5561 in 79. |

I worked construction on the marion 5900 from the first pad sat on the coal seam at the Leah’s mine. We built a Marion 7500 drag line that dug the hole for the stripper. You dig the rock seam off the coal so all the rock is on bottom then you swing around to the # 6 coal seam or the bench and start digging the high wall dirt and dump that dirt and rock on top of the lime stone rock you first dug from the face. I started when I was 19 yrs old when I was 23 I bid the oilers job on the shovel and broke in to relieve the operator. I gave the operator a break when he needed it and run the machine when he was on vacation. I did various job during my tenure as a strip miner for 23 years the mine was working out so I went under ground at the new Conant mine and worked there 8 years. E. P. A. Shut us down in 2000 because of the clean air act. We were mining coal at the lowest price per ton than any mine in the state. The mine closed and then non union mine started mining our coal reserves. Sa me coal that the union mine were shut down for mining. I had the privilege to work with some of the most talented men and coal brothers. I think about those men and the work we did all the time. I’m very thankful for the years and the U. M. W. A.

ReplyDelete