(

Satellite, the tipple's location)

The Captain Mine was, at one time, the largest surface coal mine in the world. It employed the largest shovel in the world (the Marion 6360 "The Captain") and the largest Bucket Wheel Excavator in the world (Bucyrus Erie 5872-WX) among many other pieces of equipment. All photos have been scanned in from their original photo, slide, or negative and restored. [lexyky]

The referenced link above has a lot of photos of the Captain Mine. Marion 6360 Flickr photos:

1967 and

Martin.

There is more information on this shoved in

Marion Power Shovel, where the shovel was manufactured.

The mine used to ship 6 million tons of coal by rail per year with access to both UP/MoPac and CN/GM&O. [

MidwestTrans-Load]

|

StripMine

[When built in 1965, the 6360 was the worlds largest shovel. It weighed 28 million pounds, stood 21 stories tall, had a dipper capacity of 180 CY and had a 215' boom with a 133' stick to provide the height and reach needed to strip the upper bench on the side and the deep lower bench in front. CoalAge provides a lot more stats for this shovel.] |

|

Rex ferrero posted

The Marion 6360, in the pit, stripping overburden. Captain Mine.

Mitch Rabe: Looks like this photo was taken from the wheel. |

|

Randy James posted

Captain's mine, Percy Illinois |

The stripping shovel was so big because it was designed to strip two seams of coal in one pass with the upper seam being 50 feet above the lower one. It would move on the underside of the lower seam removing the overburden of the lower seam. This overburden is what was left after mining the upper seam because, as it walked, it would also remove the overburden on its side from the upper seam. Coal was removed from both seams so when it reached the end of the pit, it would move over to the recently removed lower seam for its trip back. It would dump into the pit it had just moved from, which was on the opposite side of the upper seam it is clearing. [

stripmine] In the following picture, you can see it is working the upper seam to its left. The mine was so big that it owned several "monsters:" 4 stripping shovels, 3 walking draglines, and 2 bucket wheels. [

lexyky]

|

Rex Ferrero posted

This is an informational card that I got in 1976 when I went to work at Captain Mine. It details some information about the Marion 6360. |

|

Randy Zickefoose posted

A giant! Note the man standing behind the machine.

Todd Semko: I'm not a worker in the industry, but those buckets always seem a little small for the size of the machine behind it.

Nate Nowak: Todd Semko stripping machines are built for range and capacity. To get the material far enough away from where you're digging the boom and overall size of the machine has to be very large. And the bucket is huge up close. This particular shovel is the Captain, 180 yards, well over 200 tons every scoop, working 24/7.

Michael Mooney: Look at the maintained gantry crane on top on rails. What a trip |

PAmining

posted five photos with the comment:

Here was the world’s largest stripping shovel, the Marion 6360 “The Captain”, shown working in 1984. The Captain was the only one of its kind ever built, swung a 180 cubic yard bucket, and had an approximate operating weight of 15,000 tons! It can be seen here uncovering two coal seams at once at the Captain Mine in Illinois!

The other photos included here are either from the same mine or near by mines as well. A few photos include a 32 yard Page 752 walking dragline, along with the coal pit crew! Another photo shows a 35 yard Marion 5561 digging out of a cut. And the final photo shows a 60 yard Marion 5761 shovel and a 5560 BWX (bucket wheel excavator) passing in the pit!

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

William Oldani posted

All three of these shovels are Record Breakers. I just thought I'd put them on Display!

[Note the person that is front in center. These things make even a two story house look small!

I presume from the comments that the shovel on the left is Big Brutus, the one in the middle is a B-E 3850-B and the one on the right is the Marion 6360.

The B-E 3850 operated from Aug 13, 1964 to Dec 31, 1992.] |

|

William Oldani posted

2 Major Icons of the Mining World! The Moutaineer Shovel, the Very first of the Super Strippers The Marion 6360 "The Captain" the Largest of the Super Strippers! Both sharing the Famous Mountaineer and the Coal Train Photo of 1956! |

|

Dale Gerberding posted

One of the last photos after the fire that killed this lady. 6360 Marion.

Southwest Illinois. I believe it had the largest brake bands on it than any other machine. Company I used to work for relined the bands many a time.

did you for Brake Supply?

|

|

William J. Beck posted

The following photo is the Marion 6360 stripping shovel at Captain Mine near Percy Illinois, Perry County Illinois. This is one of my favorite photos I took while working. The photo was taken in September 1978. Note the man near the crawler, next to the tanker truck. The truck was delivering hydraulic oil for the leveling jacks, the machine is on low jack for the photo.

Was this bigger than the Gem of Egypt or the Silver Spade them two worked the area where I live and used to watch them every chance I could truly amazing machines .

I believe the GEM had a 130 cu yd bucket, the Spade was the same size machine with a longer reach and a smaller bucket -- 90 cu yd. The machine at Captain was the world's largest stripping shovel with a 180 cu yd bucket.

The 6360 weighted about 28 million pounds with ballast, the GEM and Spade weigh in about 14 to 15 million pounds.

Mark Long

the 6360 was and still is the heaviest land vehicle to ever move under its own power.

|

|

|

The Captain seen here with the Bucyrus Erie 5872WX BWE. |

The 6360 started work in 1965 and stopped when it was destroyed by fire in 1991. [

NowExtinct,

CoalAge] 16,000 acres of the Captain Mine land was donated to Illinois as part of a state park. [

TheSouthern]

Each corner of the lower frame was supported by a 16' 9" high and 66" diameter hydraulic cylinder attached to dual 45' long crawlers. The shovel carried 8,000 gallons of hydraulic fluid to operate its steering and level controls. This fluid started the fire and was a major source of fuel for the fire. It was replaced by a Marion 5900 that was parked at the nearby

Leahy Mine. But it had just a 105 CY dipper. "During her active life, the Captain shovel moved 809,300,000 cubic yards of overburden, a number far greater than any other single shovel or dragline." [

CoalAge]

Using better wash plant technology, Knight Hawk Coal is mining the waste piles in this area as Jordan Mine near Willisville, IL. [

KnightHawkCoal]

|

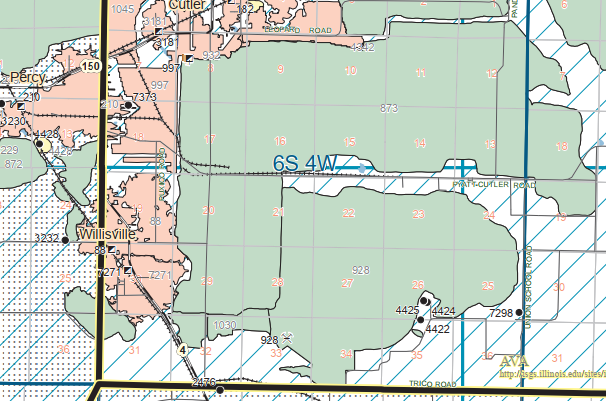

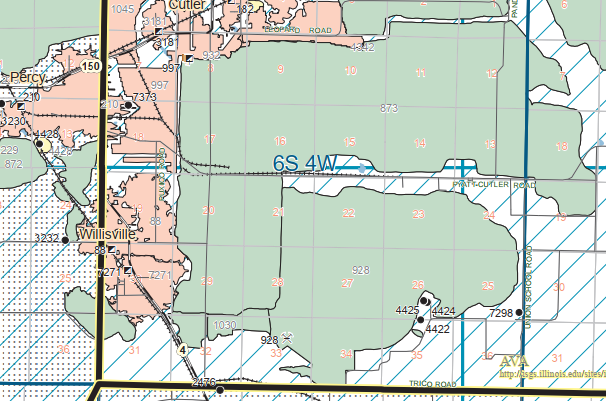

Map

[There should be a bold 873 about where the 6S 4W label is located.] |

Because the Captain Mine was adjacent to other mines, I roughly outlined where it was on this satellite image.

The railroad facilities (spurs off CN/M&O and UP/MoPac and a yard) are still intact because Southern Illinois Motor Xepress and

Midwest Transload operate a transload operation next to the tipple's property to take advantage of the rail service. (Captain Mine used to ship 6 million tons of coal each year.)

Gary Downen posted two phtos with the comment:

First is a picture of the Arch Coal's Captain Mine, the Captain pit. 2nd pic is of the Captain shovel. It is hard to imagine the size of this machine, but if you look in pit there is what looks like an endloader just to the left of the stripper's bucket, There is a pickup truck behind the shovel. On the right side of the pic is the boom of a small dragline that served as a "pull back" machine because the coal seam was so deep, the shovel could not get the material far enough away without help.

How did that loader fill the haulage trucks?

|

| 1 |

|

| 2 |

|

Dennis DeBruler commented on Anthony's comment

What is the "yellow thing" next to the shovel? It doesn't have a bed big enough to be a haul truck. Are they doing maintenance? And how did they dig out the notch in front of the shovel? Excavators were not big enough to do that job back then. |

|

William Oldani commented on Gary's post

Just for Scale, here’s a Rendering of the Captain hoisting a BE 495-B Loading Shovel! |

|

Bently Bruce posted

We did a line boring job on the Captain in the early 90's.

Steve Stern: Swing shaft? Bently Bruce: Steve Stern yes |

|

Troy Shane Bratcher posted

Finally found this size comparison picture of the BE4250w/ Marion 6360.

Charles Jones: When you look at the comparison in the illustration, Big Muskie isn't tremendously larger than the 6360. There was about what, 40 cubic yards difference between the buckets? I've not been around a lot of shovels other than the 5900 at Lynnville. But I have been on a similar size dragline to the 5900. I'll bet it would be a good race to see which machine would make the most advance in one shift. Big Muskie, or The Captain?

Dave Roberts: Yes, only 40 cubic yards difference. Muskie was 220 and The Captain was 180 |

|

Jadon Cramer commented on Troy's post

Size comparison |

|

Kevin Bridle posted

MONSTERS IN THE MIST. Captain Mine 1996, One of my favourite pictures, plenty more to see when I get to scan them in.

Nick Koba Jr. nothing like fog in the Pits , got so bad at times I had to walk and check my pumps couldn't see to drive

Kevin Bridle It was a shame, when we got down to the 5900 it was still murky but an hour later it had burnt off. |

Mike Rennie

posted seven photos with the comment: "Here are some BS #5 [actually, Captain Mine] pictures of the dirt wheel, shovel, a dozer from on top of the wheel, and a pic of some of the guys who worked in the pit. One pic of the wheel operator. When looking at the shovel on top of the bench a shot is being set off."

Patrick Creek:

BS # 2 had a wheel. My dad worked at BS # 5 and they had two Draglines.

Jerry Lacy: I’m pretty sure that this is

captain mine. The shovel looks like the 5900, and it has been repainted to arch colors so it would have been at least 1992 or later. I’m not sure when it got painted but when it was moved across the road to captain in late 1991 it was still in Amax colors.

Myron Dudenbostel: That is Captain mine's 5872 wheel and 5900 shovel!

|

| 1 |

|

| 2 |

|

3

[I think 3 and 4 are in reverse order because there is more of an explosion shown in this photo.] |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

Kevin Bridle

posted twenty photos with the comment: "

These are more pictures of our 1996 trip to the Captain Mine, the 5900 stripping shovel was down for maintenance unfortunately however it did mean that we could walk around the lower works, apologies for the quality, it was early on and the mist and light where not at their best."

William Oldani Would that be 1996????

The 5900 went to work in 1991 at Captain Galum Creek Operation!

Great Pictures!

Kevin Bridle Yes it would, we were told the Mine had 18 months left.

Heath Lange Kucks I thought the Marion 8050 at my mine was big but these things are massive monsters. Would have been awesome to see.

Kevin Bridle We knew the era of high Sulfur shallow coal was coming to an end so my brother

Mark Bridle suggested we go and see some Stripping shovels before it was too late, He wrote to the mine and asked if we could visit, they made us very welcome and we were given the royal tour although through out our travels we did have the odd comment of ''why had we flown from the UK to see their diggers''!

Tony Stephens This was Horse Creek mine.

Kevin Bridle The Captain mine complex was vast, we must have travelled miles driving across it, I have never been a mine that big.

Tony Stephens Kevin Bridle yes I worked at both Captain and Horse Creek. Awesome amount of stripping machines .

[I added the Captain Mine ISGS directory and map as comments.]

|

1

On our way down into the pit, This is a BE 195 I think.

Lee Bloxham Yes

|

|

| 2 |

|

| 3 |

|

| 4 |

|

5

MARION 5900 Stripping Shovel, 7200 tons when built! |

|

| 6 |

|

| 7 |

|

8

Under Lower works, Marion 5900 Stripping Shovel |

|

9

Front Right Crawler, Marion 5900 Stripping Shovel |

|

10

Full Set! Front crawlers Marion 5900 Stripping Shovel |

|

| 11 |

|

12

105 Cubic yard variable pitch Bucket, now that's a digger! |

|

15

The maintenance team were replacing the hoist cables I seem to remember. |

|

| 16 |

|

| 17 |

|

| 18 |

|

| 19 |

|

| 20 |

I didn't know where this part was on the shovel until I saw "Photo 20" above.

|

Rex Ferrero posted

A welder welds a wear washer on the stripper bail. You can see how big the bail pin bore was. Captain Mine. |

Kevin Bridle

posted nine photos with the comment: "

These are more pictures from our trip to the Captain Mine in 1996. These are taken from the other end of the pit when the sun had come up and the mist burnt off, the photos of the coal loader with the bucket wheel in the background give you some idea of the scale of the operation, the MARION 5900 stripper can be seen in the distance, they are some of my very favorite pictures I have ever taken in a mine."

|

| 1 |

|

| 2 |

|

| 4 |

|

5

I'm not sure what this is, a Dart maybe?

Kevin Bridle It has been suggested this a RIMPULL, any advance?

Mike Gummere That's a Rimpull. Darts didn't have the radiator on top that I know of.

Mark Bridle Darts have a front wheel with large spokes.

Bruce Rolston this is a tricky one Kev ... my gut feeling is that it's one of the Rimpull CW series of bottom dumps ... mid 70s+ manufacture ... yep the front wheel centres are typically Rimpull ... but I've seen them with the more typically 'DART' big '5 spoke' centres ... radiator more typically Rimpull as suggested but that angular 'front-on' bodywork is more DART or specifically WABCO (look at a WABCO 120 ) ... but the big giveaway to me that it is indeed a Rimpull is the trailer rather than the tractor ... oh and then to confuse things I'm sure I've got photos/brochures somewhere showing both WABCO and DART bottom dumps in almost this exact same livery ... gut feeling is that it's a RIMPULL, but in onsite repairs/upgrades etc it may have inherited bits off some 'cousin machines' ... if I were a betting man ... 5 bucks says it at least started life as a RIMPULL CW series.

Kevin Bridle Thanks Bruce, not my area of interest really I have a few more photos of them and as people are interested I'll put them up tomorrow,, I always try to capture some of the more mundane vehicles on sites, they all have a part to play. Thanks again for taking the trouble to enlighten us.

Larry J. Ashby KW Dart. |

|

| 6 |

|

| 7 |

|

| 8 |

|

9

Kyle McCracken Rimpull?

Kevin Bridle You might be right, I was a bit overwhelmed by it all and I forgot to ask, I'm not really up on Coal Haulers or bottom dumps, not some thing you see in the UK really.

Mike Gummere Yes, that is a Rimpull. |

|

| William Oldani commented on Kevin's post |

|

After the devastating fire onboard the Marion 6360, Arch was left with a huge capacity void. Now, while the 6360 was in it's "final" years according to some at the mine, it still represented a huge loss of production. At the request of mine management, the Marion 5900 (formerly of the Leahy and Denmark Mines respectively) was considered. It was a newer machine and could execute the desired double seam digging that was required by the contracts at Captain Mine during the time. It was determined to be sufficient to fill the capacity and was placed into service at the Captain Mine. Once there, it received the standard Arch livery. It continued to work at the Captain Mine until the mine was shut down.

Arch Coal Marion 5900 (Captain Mine)

Jerry Lacy I believe this machine had almost the same reach as the 6360. From what I have heard the 5900 had a higher run time and didn't slow mining as much as 75 yards of bucket capacity would seem.

Jay Wilson The cover ended up being too much for this machine. |

|

Rex Ferrero posted

This is the Marion 5900 on the top of the ground deadheading past Captain Mine’s tipple on it’s way to the pit to replace the Marion 6360 after it was destroyed by a fire.

I have helped deadhead shovels more than once. It usually requires pallets under the crawlers.

Larry J. Ashby Yep. Mat-logs. The shovel’s crawler psi is too heavy for regular ground to carry, and without mat-logs, the shovel would sink.

Pretty close to where they almost got it Stuck!

|

|

Rex Ferrero posted

The Marion 6360. This is another picture of it on top of the ground moving to a new pit.

[A comment reminds me that these were electric machines powered by a cord. So these 2 mile moves must have needed a rather long "extension cord." Note that it moves fast enough that quite a few "yellow critters" were needed to move the mats.] |

|

Rex Ferrero posted

The Marion 6360 bucket positioned for repair. Note the bucket’s double doors, and for size comparison, the men eating lunch in the shade the bucket provided. |

|

Mining Photography Archive posted

Walking the Captain towards Galum Creek.

[Note the front loader with a "tong" attachment that moved the mats from behind the machine to in front of the machine.] |

|

Rex Ferrero posted

This is the Marion 6360 on top of the ground moving to work in a new pit. It’s up on mat-logs so it won’t sink into the ground. A Marion 181 coal loader is moving with it.

Todd Rennix: Just dumbfounding. Rex Ferrero: Todd Rennix Yep. The 6360 had a 180 cubic yard bucket, the 181 had a 15 cubic yard bucket. For size comparison, if you look close, you can see a man in front of the crawlers in the lower center of the picture. Scott Hull: If it gets stuck they will need to bury it where it fell. Steve Goode: Had one turn over close to where I live. Peabody Coal Company's Gibraltar mine. Was deadheading it through a soft place. Started sinking on one side. Operator swung around and stuck the stick in the ground. Stayed on it till the boom buckled. Lot of controversy around that event.

The 180 cubic yard Marion 6360 on top of the ground moving to a new pit. South of Pinckneyville Illinois, in Perry County, in what is now Pyramid State Park….Captain Mine. Chad Litteken: Roughly what year was this? Rex Ferrero: Chad Litteken I believe the 6360 burned in September of 1991, so a year or so prior. |

Manish Magar

posted four photos with the comment: "Mighty Captain (Marion 6360)."

Travis Rickett: What years did it operate, and what happens to it

Jerry Lacy: Travis Rickett it worked 1965 to 1992 when it caught fire and very heavily damaged it. It was replaced within a few weeks by a 5900 Marion shovel that had been sitting idle nearby.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

Michael DeWayne Shaffer provided three photos in comments on Rex's second post, but with no explanation. I don't think they are the 6360.

|

| 1 |

|

| 2 |

|

| 3 |

|

William Oldani commented on Rex's post

What a Great Shot!

I remember that Well!

|

|

Mining Photography Archive posted

Enough clearance under the machine, between the crawlers, for the coal haulers to pass thru. Saved building extra ramps and haul roads.

Only two were built like that. 6360 and 5960

Little sidenote: The Captain and Big Muskie both ended up being very reliable machines. Learning to deal with the size was some of the learning curve, but they both had very good availability.

Jay Wilson some of them, yes. The haulers never really went under the 6360. It was deemed unsafe according to the mine's head of safety.

Jay Wilson biggest reason was rocks rolling off spoil.

we hauled in hydraulic oil underneath it in semis.

Back in about 1990 I helped an old man that I worked with straighten the bucket bail off of this machine.all we used was a rose bud torch and a garden hose. [Now I need to learn what a "rose bud torch" is.] |

|

Big Machine posted

The Marion 6360 |

Kevin Bridle

posted twelve photos with the comment: "

This is at the bone yard of the Captain mine [per a comment this is actually Horse Creek] in 1996, 18 months before the mine closed I believe. The last photo of the Walking Dragline was taken outside Cutler Illinois, the mines local town, We stopped and jumped the ditch, it was just parked on its own in a field!"

Gibson Smith Are those still in tact?

Michael Davis Gibson Smith well, the 8200 dragline is. It’s in Mississippi at a coal mine there. [And he posted a photo of it in action.]

Gibson Smith Got any of the 6360 captain.

Kevin Bridle No only the flag it was flying the day in burnt down.

[In a comment, William Oldani provided a video of the "energetic felling" of the 5560WX (bucket wheel excavator).]

|

1

I think this is a MARION 5761, But if any one knows better please say.

Gibson Smith 5761 fell over into a swamp.

John Alms I remember this parked at conant illinois. built for captain mine. moved to streamline, then back to captain when streamline closed. |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| 11 |

|

| 12 |

|

Dennis DeBruler commented on Tony Stephens comment on Kevin's post

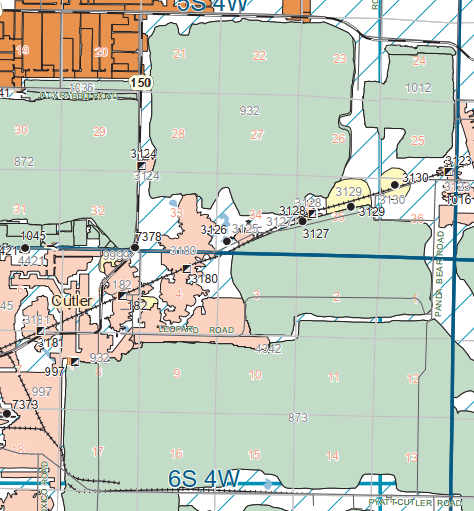

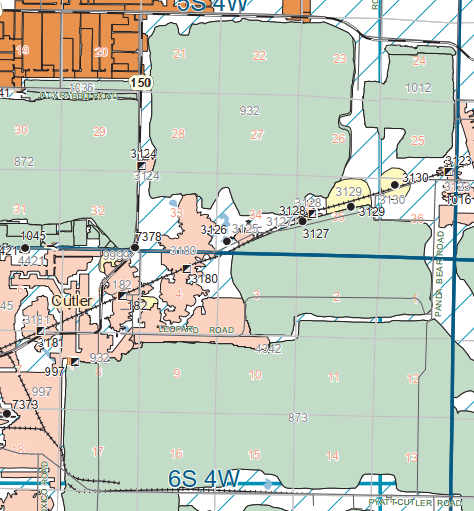

Horse Creek did the Herrin seam from 1986 to 1994. It has index 1012 in the upper-right corner of this ISGS Map extract. The equipment looks rather big for such a small mine. Was it moved here from another mine? There was a lot of mining in this area.

[Satellite] |

Carl Gilmore

posted six photos with the comment: "

This was the B-E 5872WX. Largest straight thru bucket wheel excavator at built. At Captain Mine - working same pit as the 6360. Doing pre- stripping - seem was getting too deep for 6360 by itself. WX stripped one side and spoiled on other side of pit. 700 ft long over all, 300 feet high, 40 ft diameter wheel."

God that must have got boring to operate.

not really, you had Dozers in, out and behind the digging head as well as if you were crowded back and had a full stacker belt the machine would start into a very real falling over! Many many times!

And I can attest to Wm. Oldani’s statement from first-hand experiences!

That got me thinking. As you started up the machine, the center of gravity would move from the front to the rear as the dirt moves on the conveyor through the machine.

Was the lower frame , the same as the Captain ?

the lower was smaller than the 6360.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

Scott Hankins posted

5872 wheel excavator Captain Mine

Mitch Rabe: Look at the dump distance!

Carl Gilmore: Mitch Rabe 700 feet end to end at max. crowd position of the digging ladder.

Rob Link: That was the 5860 from Consol Burning Star 3 that CDK built into a wheel.

Johnny Tapp was CDK head man.

|

%20HISTORICAL%20STRIPPING%20SHOVEL%20&%20DRAGLINE%20ARCHIVE%20_%205872%20wheel%20excavator%20Capta.png) |

| More comments on Scott's post |

|

Mining Photography Archive posted

Arch of Illinois Marion 6360 (Captain Mine)

Wayne Pruitt: That’s the narrowest pit I’ve ever seen a big machine make.

Paul Kipp: I was one of the first fire departments on the scene and I got first-hand of when it caught on fire and then after that I was out there when they were scrapping it out and it was a sad day. |

|

| 1 |

|

| 2 |

|

Rex Ferrero posted

Captain Mine. 5872WX digging head.

[40' diameter to the outside of the teeth. 36' for the bucket base. So the buckets were 2' deep. The mine fabricated new buckets. A bucket was 2.5 cu. yd.]

I remember changing buckets on that dude one time, Gil told us it would definitely take a couple hours!

Charlie Scott, Danny McFadden and I did it in little over Half an Hour!

Seems lining up the bucket was the hardest chore!

We simply imprinted the broke bucket into the bench 8” including the teeth base!

Swung over cut the old bucket off while two of us drug the new bucket into our mold!

Swung back over and the pin holes were already lined up!

|

|

Rex Ferrero posted

This is another picture of the 5872WX.

Looks like it’s been positioned sideways in the pit so that the shovel can deadhead past it. Captain Mine

Jerry Lacy: Until I seen pictures and realized that the 5872 sat on the 6 coal, I wondered how it and the 6360 passed each other in the pit. Most of the other mines in the area that had bucket wheels didn’t have that option.

Jack Hickok: The old 5860 made a good platform for that wheel. I worked on the 5860 at Norris. I liked that machine! |

|

Rex Ferrero posted

A down the pit picture of the 5872 WX as it was working.

As seen through the shovel ropes.

At Captain Mine.

Matt Wilson: We’re the shovel ropes from the 6360 or the 5900?

Rex Ferrero: Matt Wilson I think the 6360.

William Oldani: Rex Ferrero I would agree, the 5900 had a tighter equalizer anchor on the point sheaves.

It would appear the shovel was down for maintenance!

Ropes are relaxed

Myron Dudenbostel: This looks to be in the North South pit before they moved..... |

|

Rex Ferrero posted

The supply truck drives under the 6360 and then away while it’s on low jacks. There’s a man under there too. Captain Mine. |

|

Rex Ferrero posted

A picture of the Captain Mine’s Marion 6360 shovel gantry. For size comparison, there are men working there in the dead center of this picture. Also noticeable are the unmistakable double rack and pinion crowd sticks…… Don Perryman: This reminded me of a job I did. Working as a master electrician on 3rd shift. The new sticks had been installed after the wreck when they were spit out. The new sticks had heater’s installed but not wired. Every time the machine was down I would go inside the sticks and stay all shift wiring the heaters. According to where the bucket was spotted I would have to get in out by the knuckle, or walk on the sticks from the gantry and get in from the back end. Not one of my best jobs but got it done. When I got one done there was another one to do. |

Note in the directory that Southwestern owned the mine through 1983.

|

Larry Joe Jenkel posted

Matt Weyand That’s an early picture of the Captain. Looks like it has its original dipper on it. |

|

Gary Downen posted

A one of a kind haul truck built for the Arch Coal Co's Captain Mine near Cutler, IL. If you look at the cars to the right, I think this was early 1980's. The truck held 250 tons of coal. It was so big it was hard to turn around in pit. Idea was to drive in one way, walk to other end and get in that cab, then drive out. maybe some of the guys from Captain can help me on this, but it did not run very long. Too many mechanical problems, plus who would want to get out of the cab in the pit and walk to the other end every trip??

William Oldani

It was an Electrical Nightmare! This was before PLC technology! Everything had to be done mechanically! CAT actually worked out a Deal to have Captain Park them!

The Biggest Snafu was independent control between the Cabs, every once in awhile the servos would get confused and the locked out cab would try to steer!

John Lovaas

Did Caterpillar build this? I was curious who would take on a project like this.

Bruce Combs

Kress Corp. Bromfield IL.

William Oldani

Bruce Combs pretty sure they were working with Cat, Those Trucks had CAT plates all over them.

Bruce Combs

I was told Cat supplied the engine and kress made the machine in Brimfield IL.

John Lovaas

Huh! Never heard of Kress- interesting niche business. Slag pot haulers- don't hit the brakes too hard on that

http://www.kresscarrier.com/

Don Sims

John Lovaas Assembled at Cat Plant in Decatur.

John Lovaas

If this one was built in '71, Kress takes credit for it-

"Kress Corporation then built its first coal hauler in 1971. A single unit, bottom dump, coal hauler. Again, the first of its kind. Built for the Captain Mine of Southwestern Illinois Coal Corporation."

http://www.kresscarrier.com/HistoryOfKress.html#.X16rXes8KrU

Rex Ferrero

I went to work at Captain Mine in 1976, and they had been parked before I started there.

John Lovaas

A bunch of engineers standing around a machine- always a bad sign.

It looks like the machine is leaning towards the photographer- did it have suspension issues?

Anthony Rolando

A Chrysler Imperial early 60's, a Dodge pickup and late 50's Dodge or DeSoto.

Mark Behrens

Jim Pagliai built a shed out of the sides. |

|

|

Lyndon Forby posted

I wanted to share this picture of one of my father's trucks (Gerald Forby Trucking) next to a haul truck at the Captain Mine. I believe this is from the 1960's. I am so proud that our family, myself included, played a small part in the history of this great mine and many others in Southern Illinois over the past 70 + years. We have definitely hauled our fair share of coal. |

|

Nicholas S Koba Jr. commented on Lyndon's post

hare is a little better photo of that truck |

%20Illinois%20Coal%20Mines,%20Miners%20&%20Railroads%20_%20I%20wanted%20to%20share%20this%20picture%20o.png) |

| Comments on Lyndon's post |

Gary Downen

posted two photos with the comment:

Here are pics of a wheel belt line system to remove unconsolidated overburden. A system similar to this was used at the Arch Coal Co.'s Captain Mine near Cutler, IL. This mine had the biggest stripping shovel ever built, until it was lost to fire in the 1990's. As the coal seam got deeper, the bucket wheel excavator did not have the reach to move material across the open pit. This system had a wheel loader on the high wall side, pic on the right, which loaded the overburden onto a belt line system that carried the material along the high wall, around the end of the pit, then ran along the spoil side of the pit. Then you had a setup like in the pic on the left that took the material from the belt line and distributed it. There were a lot of problems with this set up, and it did not run very long. Hopefully some of the old Captain miners can add to this.

The Captain “Round Pit Wheel” system was made up of three manufacturing company’s:

O & K

Mitsubishi

Wesserhut

It was made up of 4 O&K 680 BWE

A half a dozen O &K Belt Bridges

2 Mitsubishi Bridges 180’ for end of pit Highwall transfer.

3 Mitsubishi Spreaders and Transfer Belts

It was an excellent system but at a time (early 70’s) when a significant portion of Upper management were nothing more than Old Pit bosses that somebody with money liked it wasn’t received well!

The Captain wheel system was labor intensive but very effective and productive for Midwest surface mining.

Because of the system, Captain received a Topsoil Variance from the State of Illinois that allowed mixing Glacial clays(Blue Mud)up to 60’ deep with existing topsoil 14” as a Top Soil Substitute!

That’s all I’m going to say about that!

|

| 1 |

|

| 2 |

|

Nick Stork commented on Gary's post

The transporters were bought by Bollmeier construction co. And one of them was made I to this dredging machine. The other is sitting in their yard. We scavenged parts off of the spare over the years to keep the one going. They had a very complicated hydraulic system that is a pain. I managed the company for several years.

After I noticed how tall a track was because someone is standing at the end of one, I noticed that the cab is a little box on top.

|

In Sept 2020, I got hit with a Double Doomsday. Both Facebook and Google changed their software. I said "changed" instead of "updated" because the new software is not better. In fact, Google's Blogger software is far worse except for a search function that works. Specifically, it has three bugs concerning photos and their captions. So I'm no longer copying photos and interesting comments from Facebook. I'm just saving the link. I hope you can access posts in Private Groups.

"My drawing shows 716 ft the same as the final machine dimensions. The Ballast issued arose when the weight of the digging ladder compromised the C.G. When the Stacker was full and and the machine crowd was in maximum Retract."

[I'm violating my new policy already. This diagram is just too neat to not include.]

|

William Oldani commented on Dale Gerberding's post

[The BWE removed the dirt spoils and the shovel removed the rock spoils.] |

Social media at its best. This was a fantastic education concerning the surface mining industry.

|

Larry Joe Jenkel posted

Myron Dudenbostel: Coming into the east incline....

[Larry also posted some more detailed photos of the wheel excavator on Dec 24, 2021.] |

The mine evidently also had a

P&H 5700LR called Big Don.

|

Richard Vinson White Sr. posted, cropped

Mark Hardwick: Truck size didn’t catch up fast enough to make many in a loading application.

Dylan Becker Young: Mark Hardwick wasn’t used for truck loading…try reclamation.

Jerry Lacy: Mark Hardwick I read somewhere that they did load trucks with it on a pit extension. Mostly though it was used to move the parting between the two coal seams.

Dave Morse: Jerry Lacy I loaded under it when they were extending the 6360 pit in the south end!!

Richard Vinson White Sr.: Arch, Captain Mine.

Matthew Bradshaw: Than went to West Virginia.

Jennings Ellison: Matthew Bradshaw what mine in WV did it go to?

William Oldani: Jennings Ellison Ruffner Mine they put a 54 YRD Bucket on it and reinforce the Boom!

Gary W. Harris: William Oldani I put a truckload of fuses and SCR's in that machine over the years. Then we broke the point sheaves off the boom and that was the end.

Rod Drummond: Don Perryman the fuses where expensive too

[Some comments indicated that it had maitenance issues because its drives were ahead of their time.]

Bruce Brown: Wow that's one hell of a set of long range sticks on there! |

That was a sad day indeed!

My oldest son and I were there to witness “The Wheel’s” destruction.

After so many toppling over close calls during her relatively short life, she refused the first attempt to be put down with explosives!

The 5872 was truly a unique “Modern Marvel”, being THE largest cross-pit BWE in the world.

At over 275’ tall, 713’ long, and standing on a set of eight crawlers having a combined footprint of only 64’ x 64’, she did what she was designed to do!

|

safe_image for The Captains Final Hours Episode 1

David Perardi: First time I have heard it. Thanks for sharing. I’ll never forget going to work that morning and all the tough days that followed. Fortunately for everyone’s jobs we had an idled stripping shovel, a Marion 5900, from the Denmark (Leahy) Mine sitting across the road, approximately 7 miles from the 6360 pit. The day immediately after the fire the gears were set in motion to move the 5900 to the Captain pit and replace the burned out 6360. If not for that long 7 mile journey that took several days, a lot of jobs would have been lost. |

|

safe_image for The Captains Final Hours Episode 2

Mitch Rabe: Thank you so much for this! I think it is interesting how some of the people in the interview cannot contemplate how someone would speculate on the fire being intentional. The reserve had 7-8 years left, a 5900 was ready across the road, the machine was insured for $35 million. I think it would be very very reasonable for someone to assume sabotage. I know I did for many years when my dad first told me about this years and years ago. But what complicates the story is if the electrician did indeed do something to start the fire intentionally he would be at risking his own personal freedom for attempted manslaughter as well as the obvious arson. I know personally a man who started fire to a Wal-Mart and he has several attempted manslaughter charges added onto his arson charge because of the workers inside when it was on fire. He is now in federal prison for several decades of his life. I don’t think it was intentional because I know how greedy and production hungry coal mines are. I don’t think they would have traded the lost production going from the 6360 to the 5900 over a seven or eight year period for the $35 million insurance payout. Of course I would have to do the math on that going off of what coal was priced at during that year.

Jerry Lacy: Mitch Rabe I wonder if that speculation was because the master electrician on this machine was the same master electrician as was at streamline tipple when it burned, or at least that’s what I have heard. If that’s the case it would be either bad luck or on purpose.

|

William Oldani

posted three diagrams with the comment: "Came across these from 1984, the first Two were 5872WX Concept Drawings I made! The last one is the Final Range Drawing Bucyrus Used to Make the Cross Pit Wheel Excavator, The largest Ever!"

Matthew Wilson: These are great WEO. When did the 5872 officially start work?

William Oldani: Matthew Wilson I'm thinking May/June of 85.

Steve Pifer: I think the 5872WXwas built on the lowers works of a parked Marion shovel.

Evin Fritsche: So was the wheel excavator way ahead of the shovel?

|

| 1 |

|

| 2 |

|

| 3 |

|

William commented on Steve's comment

That's Correct, Consols 5860 Shovel was purchase by Arch Mineral and Moved to Captain where it was Transformed into the Wheel!

Alex Taylor: William Oldani did the 5860 work at all as a shovel for Arch or was it changed as soon as it arrived?

William Oldani: Alex Taylor it was bought for the Wheel Base.

Alex Taylor: William Oldani was any of the shovel front end transported to Arch or left behind?

William Oldani: Alex Taylor it was scrapped.

|

|

William answered Evin's question

The Wheel followed the Shovel! |

Rex Ferrero

posted 8 diagrams for the "Marion 5900 crowd stick wreck in the mid-1990s when the 5900 was working at Captain Mine."

%20HISTORICAL%20STRIPPING%20SHOVEL%20&%20DRAGLINE%20ARCHIVE%20_%205872%20wheel%20excavator%20Capta.png)

%20Illinois%20Coal%20Mines,%20Miners%20&%20Railroads%20_%20I%20wanted%20to%20share%20this%20picture%20o.png)

No comments:

Post a Comment