While looking at photos of the Bong Bridge, I noticed a smokestack the background. Any tall smokestack still standing in the 21st Century is Industrial History of some sort.

The power plant became operational in 1931 and burned residual fuel oil. [EnergyJustice]

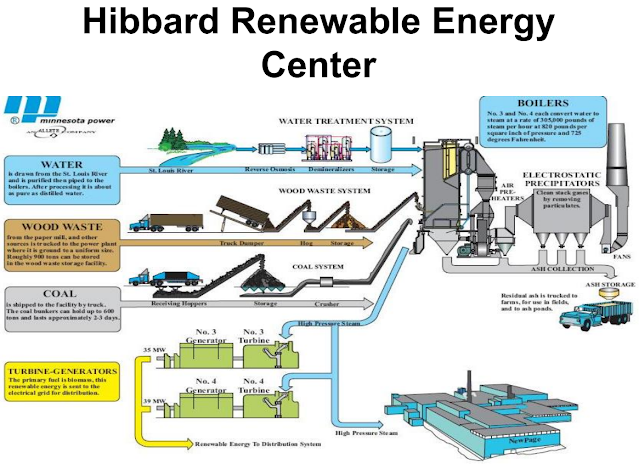

Units #3 and #4 were added in 1947 and 1951, respectively. Unit #3 now has a capacity of 35 MW, and #4 is capable of 39 MW; so this is a small plant of only 74 MW. It was closed in 1982 "due to economic downturn and rising production costs." It was started up again in 1987 to burn wood with coal to provide process steam to the nearby paper mill. (You can tell that the paper industry is struggling because I've seen three names for the mill: Lake Superior Paper Industries, New Page and Verso Duluth Paper Mill.) In 2009, Minnesota Power bought units #3 and #4 from the City of Duluth for $2.5m with the intention of investing 20m to increase the plants capacity so that the percentage of electricity generated from renewable energy would be higher. It is not clear why the city owned the plant until 2009. This expansion was expected to produce 210 GWH annually from mostly wood waste. [HeatingTheMidwest, DuluthNewsTribune]

|

| Kris Spenningsby of Minnesota Power [HeatingTheMidwest, p1] |

The two upgraded boilers can burn wood, coal and/or gas. But this satellite image indicates that they really do burn wood waste. In fact, the mix is a 10/90 coal to biomass ratio. The narrow beige building on the right stores the biomass. We can see that the plant is operational because there is a truck being dumped at the bottom of the image. (Typically, satellite images are just a few years old. [EnergyJustice]

|

| 3D Satellite |

The stack is 331' tall. [pca, p5]

|

| MNpower |

Most of the waste comes from forestry operations within 100 miles of Duluth. But in 2016 the plant burned about 9,000 tons of storm debris created by a July 21 storm. And they anticipated burning storm debris from an extended area for another 6-12 months. [MNpower] Hibbard also burns the bark from the adjacent paper mill saving them the cost of disposing of waste. The bark and storm debris is cheap. But in general, biomass has become expensive because of increased competition for the waste. The building stores 900 tons, but the plant burns over 1,000 tons a day. (Unlike coal, biomass must be kept dry.) So a continuous 7-day/week parade of trucks is needed to supply the wood waste. But they can switch to burning just coal if their biomass supply is interrupted. One advantage of consuming incoming waste within 24 hours is that they don't have to worry about it growing some mold. Mold causes the waste to cake which can reduce the flow of the fuel to the boiler. The quick consumption also reduces the risk of spontaneous combustion. In contrast to moist conditions creating mold, dust is also an issue. All of the wood handling is done inside negative pressure enclosures and the air sucked out of the enclosures is run through a filter in a baghouse. And they grind the waste on site so that the trucks are hauling material with a larger size. Furthermore, there are problems burning wood in a boiler that was designed to burn coal. One is "sparklers." It sounds like these are glowing embers that didn't get totally consumed in the combustion chamber and that can cause fires in the particulate removal equipment. (Boilers that are installed in paper mills to burn their wood waste have a different design and can burn waste that has been stored in the rain and snow.) [BiomassMagazine via EnergyJustice (The City of Duluth still owns 50% of the plant.); pca]

|

| HeatingTheMidwest, p5 [Remember, you can click the image, then right-click it to save it disk, then zoom and pan it with your favorite photo viewer.] |

Hibbard produces steam for the paper mill 24 hours a day. This keeps the boilers hot so that Hibbard can be used as a peaking plant. Other renewable sources such as solar and wind can't control when they generate power, but wood can generate power when it is needed, and when the wholesale rates are highest. [MNpower]

I read this article before I read some of the others referenced above. I was left with the impression that the $100m upgrade was effectively a public relations stunt to increase the renewable energy percentage that Minnesota Power could claim. But that, in practice, the plant is generating very little electricity. So the ratepayers are having to suffer the burden of the $100m capital cost.

But the article seems to assume that the electricity generated by a power plant would go to the grid. Specifically, it assumes that "rarely dispatched by MISO" means "rarely generating power." But "The Duluth facility typically generates about 50 MW from a 10-90 coal to biomass ratio." [BiomassMagazine] And:

|

| EnergyJustice, unfortunately, the "red text link" is broken. |

So Minnesota Power does not want to provide electricity to the grid with this plant because it has already sold the power, not because they don't want to run it! Not only that, it is selling steam. So it has two streams of revenue, and it is helping the ratepayer by paying off the capital cost itself. What is even more disconcerting is the mistake of not distinguishing between generating power and suplying the grid by the Public Utilities Commission, not the author. It is the job of the PUC to understand that contracted electricity and steam helps the ratepayer! (I seldom use exclamation marks. But I see this is a two "bang" paragraph.)

No comments:

Post a Comment