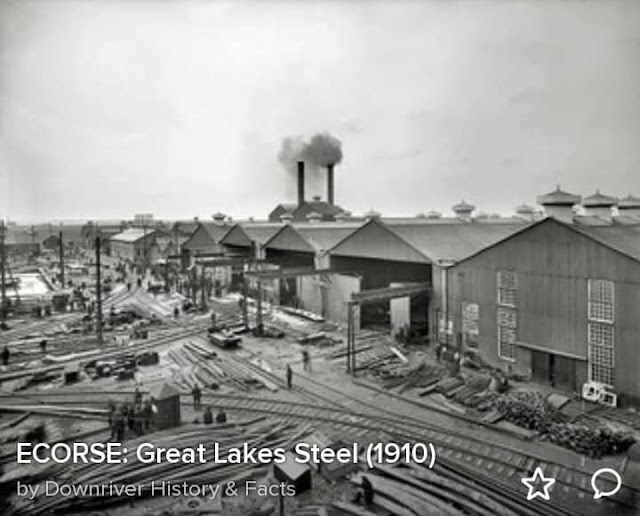

"George Fink, a steel man from the East founded Michigan Steel Corporation in Ecorse, Michigan in 1928 and expanded it to Great Lakes Steel in 1929." [MeanderingMichiganHistory]

Mark Jobin posted three photos with the comment: "Great Lakes Steel in 2003 from Main Plant to Zug Island."

Steve Litwin: I remember this time well, the trucks going in and off the island never stopped. It was constant from 7 am until about 4 in the afternoon.. The smell of the Levy slag haulers , with steam rising out of trucks going down Jefferson to Dearborn, on to the Levy yards on Dix.. The Delray Cafe bustling at lunchtime. Good times...

|

| 1 |

|

| 2 |

|

| 3 |

|

| Kevin Nelson posted Early days of Great Lakes Steel. |

.jpg) |

| Anonymous participant posted Zug Island [According to some comments: "the dirtiest square mile in the US." This photo must have been taken from the Gordie Howe Bridge.] Michael Maitland: From the blasts to the finishing in the distance, what is still operating, or planned on operating if market warrants? Robert Borg: On Island only thing left running is Coke ovens which are owned by DTE Energy. At main mill i know a pickling line, Galvanizing line and I think annealing are what's left running. Sad. Detroit has gone from 9 blast furnaces to just 1 at Cliffs Dearborn works. Josh Roach: Cold rolling and finishing is what’s left operating. Spent 6 years on zug before being laid off then called back to cold rolling. |

|

| Craig Hensley Photography posted A high and wide angle view of the DCRR yard on Zug Island. This was shot this earlier in the year as an NS interchange job was shoving their train into a yard track. Detroit, MI - March 2025 Veronica N Matt Bentley: A Ghost town of what it used to be! 🤔. Did you hear about the talks of selling Zug island? The EPA stated that they would have to dig 80 to 100 feet down to remove the contaminated soil. (and there were no guarantee's!) No more island, I guess! Peter Bassett: What type of operation was and is presently running on Zug Island? Lots of tank cars. Kevin Nelson: Peter Bassett Blast furnace facility for Hanna Furnace then National Steel and eventually US Steel. Currently the coke plant operated by EES, a division of DTE Energy, is the only manufacturing taking place on Zug. Craig Hensley Photography: Kevin Nelson there is some new life for the Coking facility. CSX has started taking unit Coke trains from Zug to Gary IN. From my understanding, it’s a new daily run for them, one empty and one load per day. |

|

| Dan Beneteau posted People look at me strange when I say I miss the island Branden Michael: Coke Plant Still Going Strong. James Torgeson: Branden Michael But owned by DTE/Detroit Edison. Richard Travis: Uss was the worst thing that happened to zug and gls as a whole ran the place into the ground. Bradlee Gregory: They wanted all the blast furnaces to run the same. They took info from the guys at Gary works and trued to adapt the furnaces at Zug to run the same way. They made so much terrible iron. I worked in the BOP and at time we had surfers so high it should’ve been dumped on the ground and disposed of. But they made us process it and use it. Our area manager was in charge of the blast furnaces and he started pulling paperwork from years past showing how they made more and better iron in years past. They transferred him to the main plant. They didn’t wanna hear any of that. Just conform to our new ways or get out of our way. Chris Heintz: Richard Travis they are doing it at GCW [Granite City Works] also. Alex Potichnyj: If I remember correctly it’s one of the most polluted places in North America. |

|

| Phil Jadlowiec posted US Steel Zug Island |

|

| Craig Hensley Photography posted NS BD27 shoves their train of coils into the yard on Zug Island as the sun begins to set over Detroit. NS BD27 - Detroit, MI - March 2025 Nick Breznai shared |

|

| Mike Dropiewski posted Ore Docks and D-4 Furnace on Zug island... Mike Dropiewski: There was a C furnace but that blew up that was in-between A-B furnaces and D-4 was South of them. Not quite sure why they were separated. Ova Fletcher: Mike Dropiewski The furnaces' designed by Moore, were built in the early 50's. D4 was added when the market for steel increased. There was no room for a furnace, stoves, dust catcher, and gas cleaning equipment. I worked a shutdown on A furnace in 1969. C Furnace was also down. There was a water cooled ring, looked like a wagon wheel in the horizontal position, under the carbon blocks at the bottom of the hearth. I asked the boss if that wasn't a stupid idea? Well, it blew up years later, knocking the cast house crane down and killing 2 people. About 1998, I was the boss taking down the Downcommer, gas cleaning equipment, the uptakes, the crossover, and the furnace proper to the gas seal platform. IW'ers removed the structural steel and the bull wheel platform. The mill personnel were great to work with. I spent many years working the furnaces on Zug. Our government, representatives did not understand how vital the steel making industry was to our nation. Jobs and technology were exported to other nations. Now we have an idiot for a president that has no understanding of what it will take for our democracy to survive. Steel is one crucial part of that equation. If this nation ever gets into modern technology of iron refinement to make quality steer, it will take an enormous effort to rise to a world leader. |

|

| Neil Schultheiss commented on Mike's post Sykes was loading Coke on the face of Zug, we were delivering mail to them. |

|

| Neil Schultheiss commented on Mike's post |

|

| Neil Schultheiss commented on Mike's post |

|

| Ray Belcher commented on Mike's post, cropped D4 Blast furnace in February of 2020 |

|

| Branden Burtcho posted, cropped "Retired" USS A blast furnace on zug Island in Detroit MI. Photo was taken while doing my fire/explosion system inspection on a pulverized coal tower/silo (tallest point on zug island) . With the city of Detroit in the background. Tis was shut down years prior. D4 furnace was the last standing but is now shut down . No more blasting on zug island... |

|

| Wade Klaffer commented on Branden's post, cropped Here is B&C |

|

| Jessica Van Giana posted 5 years ago today [or Mar 31, 2020] the final blowdown began. Ending iron making on Zug Island. |

|

| Brenda Padgett posted Zug Island Detroit Michigan Took this picture from our boat Phil Jadlowiec shared Sharing from another group Donald Hill: Looks to me like the D4 furnace. Kevin Nelson: B2 furnace. You can see the top of A1 to the left. |

Mark Jobin posted two photos with the comment: "Great Lakes Steel Main Plant Past and 1989."

Roger Etch: Getting rid of open hearths and ingot pouring/stripping/soaking operations eliminated a lot of buildings.

Steve Haynes: Roger Etch True, but remember it was originally thought that continuous cast steel slabs would produce a substandard product. Some believed that skipping the process of running ingots through the primary mill would result in less than the best slabs. Of course, it wasn't true, but that had to be learned. USS Gary Works first continuous caster was protected as though the technology was a state secret.

Patrick N Johnston: Started in 76 there were 11,000+ workers

After the 95 "Force Reduction" 3000 or less.

|

| 1 |

|

| 2 |

Mark Jobin posted three photos with the comment: "National Steel Great Lake Steel Zug Island 1987."

|

| 1 |

|

| 2 |

|

| 3 |

|

| Mike Delaney posted First iron ore load into Detroit Iron & Steel Zug island saying 1903-04ish. Detroit Public Library photo. |

|

| Mike commented on his post |

|

| Mike commented on his post |

|

| Mike Theisler commented on Mike's post |

|

| Dale Groh posted US Steel - Great Lakes Works - Blast Furnace Configuration Ron Wechsler: Counter Current Pressure Vessel... Kevin Nelson: Showing a 2 bell top and a representation of the compact bell-less top that was on A1 furnace. |

|

| Kevin Nelson posted Detroit Free Press 09-May-1926 The caption reads: Zug Island, home of the Hanna Furnace company, where 750 tons of pig iron are produced each day of the year by two huge blast furnaces. All production of the plant is marketed in Detroit among automobile, stove and radiator factories. The location of the furnaces is ideal in that water advantages, market and raw products are close at hand. |

|

| Dale Groh posted John Groves: I think this picture is no later than mid-1940s, not 1954. In 1947 or 1948 a 5th open hearth furnace was added to No. 2 shop, as well as 2 x 25t Bessemer converters for duplexing. |

.jpg) |

| Mel posted |

|

| Chris Leigh commented on Mel's post |

Mark Jobin posted four photos with the comment: "Pictures from National Steel Great Lakes Steel 1944."

Chris Pinkney: Are those the buildings near the Ecorse creek, On the west side of Jefferson?

Kevin Nelson: Chris Pinkney Yes, Chris. That's where these were located. On the south side of Mill St. between Jefferson Ave and the creek, in Ecorse.

|

| 1 |

|

| 2 [Armor plate would be a big deal in 1944.] |

|

| 3 |

|

| 4 |

|

| Dale Groh posted This is a 1957 view of Great Lakes Steel, a division of National Steel. This is a view from the river looking North-west. [This shows the fifth stack.] Phil Little: Cool, no No.1 BOP, no No.2 BOP, no EAF, no Casters, no EGL, and it looks like no 80" |

Mark Jobin posted four photos with the comment: "National Steel Great Lakes Steel 1977 1 Caster drawings and Actual Turret."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

Charles Geletzke Jr. posted six photos with the comment: "Here is a collection of photos of the Great Lakes Steel Corporation's Michigan Division plant located in Ecorse, Michigan, which was served by both the D&TSL and the New York Central. The D&TSL serviced the plant from its opening on July 23, 1923; however, during 1931 the Shore Line entered into a contract with the NYC giving them authority to construct a crossover of D&TSL main tracks at Ecorse (Mill St.), with the required interlocking protection, to make a connection with the Shore Line's Lead into Michigan Steel giving the NYC access to the plant. From August 16, 1931 forward, the NYC would perform all switching within the mill. I believe the plant was last serviced by rail in 1969. All details may be found in the book: THE DETROIT & TOLEDO SHORE LINE RAILROAD-EXPRESSWAY FOR INDUSTRY. (All photos are from the Dale Groh collection)"

James Anders: Rumor had it this was the last plant in the US that could roll 16 inch plate steel and the US government paid to keep the plant serviceable in case of war.

|

| 1 |

|

| 2 |

|

| 3 |

|

|

| 5 |

|

| 6 |

|

| 0:15 video B2 Furnace “burp”. Zug Island. Roger Norton: This is why the new bridge and Zug Island iron making could never coexist. When they finalized that location for the bridge it was game over. [Some comments talk about the burden slipping. I think this means that it got stuck and then all of a sudden falls down.] |

%20Steel%20Mill%20Pictorial%20_%20B2%20Furnace%20%E2%80%9Cburp%E2%80%9D%20_%20Facebook.png) |

| Comments on the above video |

"Great Lakes Works has an annual raw steelmaking capability of approximately 3.8 million net tons." [USS-great-lakes-works]

(Update: CrainsDetroit says US Steel may close much more than just one blast furnace causing 1,545 instead of 200 employees to be laid off indefinitely. It plans to shift production to its Gary Works. The hot strip mill is also now part of the shutdown plans. "President Donald Trump's tariffs on imported Chinese steel two years ago may have contributed to the pinch by boosting U.S. output just as the global economy was cooling, undercutting demand and dropping prices, according to Bloomberg. Back then, CEO David Burritt hailed the tariffs and the company responded by restarting two blast furnaces and rehiring steel workers. Now, U.S. Steel is facing harsh scrutiny." The first blast furnace was built on Zug Island in 1902, but US Steel has owned the operation only from 2003. (It bought the plant from National Steel. [PressReader]) It has consistently violated EPA regulations the past three years.)

|

| Kevin Nelson posted Zug Island Aerial Map with identifiers. Ted Fortier: I think thats a pretty old image. Most of the conveyors on the detroit river are gone now. Hard to tell without zooming in better. B2 should have a shiny new scrubber next to the cast house if its recent. If I recall the foundation for A1 has been removed to. Josh Roach: Ted Fortier that’s a fairly recent picture. A1 is still standing and the foundation for c furnace is still there. |

Mike Delaney posted three images with the comment: "National Steel, Great Lakes Division."

Ron Cooper: Anything still open there?

Ray Belcher: Ron Cooper Cold mill finishing.

I had almost 28 years when USS Steel bought National in 2003 . Retired in 2020 with 44 years total.

Robert Barry: Did GLW ever have open hearth furnaces? I know a good bit of the history of Zug but not much of the main mill

John Groves

Robert Barry asked above if Great Lakes ever had open hearth furnaces. Not only had OHs, but were actually a world leader (along with its National Steel sister plant at Weirton) in the operation of huge OHs, up to 550 ton heat size.

No.1 OH shop was built with 12 x 150t furnaces between 1930 and 1936. No.2 shop with 4 similar OHs was operating by 1938, lifting total steel capacity to almost 2 Mtpa.

Around 1947 or 48, all the OHs had been enlarged to 225t each and two x 25t Bessemer converters plus one more OH added to No.2 shop to boost output by duplexing (blowing the molten pig iron first in the converter then finishing the steelmaking process in the OHs).

From 1951 to 1960, fifteen of the 17 OHs were enlarged to 500t or 550t, and the Bessemer converters enlarged to 40t heats, boosting steel capacity to 3.7Mtpa.

The world's first very large BOF shop with 2 x 300t converters was built in the No.2 OH shop in 1962. The No.1 OH shop was replaced in 1970 by a second BOF shop (2 x 200t), and by a 1968- vintage 2 x 150/185t EAF shop.

In 1981 Great Lakes was downsided from 4 BF to 2 BF operation and the No.1 BOF shop was permanently closed, cutting steel capacity from 6Mtpa to around 3Mtpa. The EAF shop was closed about 1989, but the No.2 BOF continued to make steel until 2020.

|

| 1 |

|

| 2 |

|

| 3 |

Mike Delaney posted four images:

Toby Salisbury: Another plant that was the victim of USS mismanagement. USS should have the corporate statement of " we make steel at the highest cost per ton while demoralizing our workers and once we ruin a plant we walk away to concentrate on our next victim". Big river will be turned into the most unproductive electric furnace operation in the world, just wait and see.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Willy Garces, Jul 2019, cropped [This is just the northern part of the BOP.] |

|

| safe_image for NewsHerald link [This photo was taken at the end of 1 Quality Drive. So we are seeing some of the mill buildings in the BOP.] |

(source)

Lukas Irons I am reading on the western board that Zug Island will get the same treatment as Granite City....shut down for huge makeover and reopen a long time from now.

B2 appears to be one of three blast furnaces on Zug Island. There are two at the north end.

|

| 3D Satellite |

|

| 3D Satellite |

|

| The dirtiest square mile in Michigan Peter Dudley shared Most industrial operations on Zug Island are expected to shut down soon. In German, "zug" means train. Detroit & Lima Northern Railway (D&LN, a predecessor of Detroit, Toledo & Ironton Railroad) completed its mainline across Zug Island (along with two swing bridges) in 1898. Curt Vote Anything to do with the planned Gordie Howe bridge nearby? Bob Daykin No, just the administration's steel tariffs backfiring. USS had record profit at first... then demand started to pull back. Overseas customers found other suppliers, domestic buyers either cut back, cancelled big projects or found substitutes. Exemptions from the tariffs were only going to palsy-walsy friends of the White House. In the end, the American workers pay the price. Again. Ken Hissong Bob Daykin You forget about EPA fuel standards and auto makers using more and more aluminum. |

|

| safe_image for Zug Island steel operations to be silenced within weeks The company starting on April 1 will begin to lay off up to 1,500 employees — most of its 1,644 workforce — as it idles blast furnaces and stops all iron and steelmaking at the facility which has been involved in producing steel for over a century. The company has not said whether the closure of operations is permanent, only that there is no time frame attached. Robert Borg Lukas Irons have been told they are shutting furnaces down completely. So if the dont re-start them by November or winterize them. Great lakes will be done for good. At least the hot side. |

|

| Dale Groh commented on a post A1 to the left, C3 in the middle and B2 to the right. |

|

| Kevin Nelson posted National Steel Corp. Zug Island Blast Furnaces: A1 on the left. C3 in the center. B2 on the right. 1980's. B2 furnace never restarted after an upgrade in 2019, new drives and pre-con tower. D4 ran until March 31, 2020. This photo was taken shortly after a major furnace rebuild [of A1]. |

|

| Comments on Kevin's post |

|

| INDUSTRIAL CULTURE & PHOTOGRAPHY posted

The Zug Island works in Detroit were shutdown for good today. The end of era after 119 years of steel making.

Thanks US Steel for never lettting me in.

*Rust in Peace*

(photographer unknown)

Steven McKay Michael R Valentine having worked for USS the security were even worse to their employees than the public. Michael R Valentine Steven McKay As an employee?? Steven McKay Michael R Valentine pretty much do everything they could to you besides a strip search. Michael R Valentine Steven McKay Dam. While I am sad the plant shut, US Stell as a company has been rotten for decades. an Hapsias Steven McKay they aren’t as bad as they used to be these days, go figure. Still subject to random bag searches and car searches though. A.j. Kinney The facility isn’t “shut down” entirely. Iron ore production is done, and the hot strip mill will be permanently idled later this year. All but one blast have been idled for over a year (at least), with the last blast being idled today. It’s worth noting that parts of the island will still be in use for some time (specialty processes), along with the BOP down the street... Eric Youngs A.j. Kinney yeah the coke battery isn’t shutting down anytime soon. [the coke plant is probably the worse polluter.] Kurt Weber ["last case" logo shirt] https://www.mohawk-design.com/.../zug-island-blast... |

|

| John Fry posted The torpedo cars and locomotives that once served US Steel on Detroit's Zug island rust away in the weeds. Having been here when the mills were booming I never would have imagined this massive cog in America's industrial wheel being shuttered, but since 2020, here we are. |

|

| Sgteve McCormick commented on a post Kevin Nelson posted That's all y'all...... Gela Marie Maybe some of the smog will subside. Kevin Nelson Gela Marie Probably not as much as you think. The DTE Coke making facility will still be running. Eric Banta Coke plant will be idled indefinitely 2022. Eric Banta River Rouge is also bracing for the 2022 closure of the DTE Energy Co. coal-fired plant. Kevin Nelson Ronald Martin Finishing steel only from this point on. Don't know for how long that will last. Kevin Nelson Richard Bryce US Steel announced more blast furnaces will be going off line. In Indiana and Illinois. Plants in Lorain Ohio and Texas are being shutdown in May. Richard Kulpa I just hope they’re held responsible to get the Island cleanup ASAP unlike McLouth steel and so many others who closed themselves then left their properties for the Cities to clean up . Then went onwards opening up somewhere else, make these companies responsible for clean up. Bill Robinson United States Steel Corp is and has been part of our industrial manufacturing downfall for some time now. The union played right into managements future plans for flushing all the legacy costs associated with present and future retiree's down the sewer. Most retiree's were downgraded as much as 40% of their pensions when USS bought National Steel. I believe a high managment/CEO type named SURMA came along and negotiated on behalf of UnitedStatesSteel to allow National Steel employees to continue on as USS or take the flush/early buy out. The original named Hanna Furnace evolved into what was named Great Lakes Steel Corp. Management once again got too greedy and thought they could co-habitat with the Japanese Industry in the late 70's. This resulted in the Japanese owning 51% of Great Lakes Steel. The Japanese could not make a profit on their 51% during the 78-79 recession period. They sold out to what became known as Nation Steel Corp. Now here is where the Senior Management completely failed all employees of National Steel during the following years after 1980. They bought a Drug Manufacturing Business out in California in hopes of expanding and writing off business losses as a consequence of the Japanese leaving a back up void on the books. Well, now along came the lurking United States Steel Corp. History shows clearly that integrated steel mills were not technologically capable of supporting the logistical waste of labor and material. Mini mills cut into the market immediately after 1980 and thus an integrated steel mill era was crumbling before our eyes. Foreign By-products used in the making of steel were imported from all over the world. A great amount of these products were garbage material that was eventually sold as 2nd & 3rd rate mkt mtl. Bill Robinson 1st job before I went to Vietnam was a 2.35 cents/hr job class-1 laborer on Zug Island in 1967. Dirtiest job was cleaning out the flumes under the 80" mill slab casters. Still remember the smell of the cement bins loaded with sulphuric Acid. |

|

| Kevin Nelson posted 5 years ago today [Mar 29, 2025] the final blowdown began. Ending iron making on Zug Island. Danny Salisbury: When the Grim Reaper (USS) bought National Steel D-4 furnace became the most productive furnace in all of U.S. Steel and B-2 Furnace was #3. My guess is one of the Granite City Furnaces became #2. It didn’t take long for the crazies USS brought in to manage the operation to throw the USS monkey wrench into the works. One of the wackos they brought in was quoted as saying “These people don’t know how to make iron” 😂😂🤡🤡. What a bunch of clowns, they took a smooth productive operation and turned it into a crisis everyday type of clown show. Furnace crashes, freeze ups, cutting tuyeres, high thermocouple temps around the taphole, water going into furnace. You name the problem, they had it, they created it. It was unreal and really sad to watch what was once such a smooth operation turn into total mayhem. Bradlee Gregory: Danny Salisbury when management wanted all blast furnaces to run alike, things went terribly wrong. These people couldn’t understand how the blast furnace worked and iron output went way down. Danny Salisbury: Bradlee Gregory…you are exactly right. One of the worst things for USS was to have that Blast Furnace Engineering and Technology Group. The saddest story of them all was the Blast Furnace at Fairfield which was considered by REAL blast furnace people to be the best designed furnace in North America and those clowns 🤡 could not even run that one efficiently. They actually hired the best blast furnace man in the country to run that furnace at one time and he quit after only 3 months due to constant interference from the BFET Group. What a shame that the combination of arrogance, stupidity, and ignorance destroyed so many opportunities U.S. Steel had. Thousands of people and cities and towns have suffered all over America because of their warped irrational management style that led to plant closings. |

|

| Bruce Raymond posted, cropped A, and B furnaces from Zug Island. Snapped this from the Zippo ran off of D furnace. Adam Enea What is the water treatment facility for? (Assuming that’s what’s going on in the center of the photo.) Mike Maddog Madigan Yep I had 2 1 million two hunderd thou gallons in my scrubber. ODS style pumps to discharge the sludge to a drum filter system.. it pulled a vaccume to pull the water through a cloth mesh and the [cake] fell into a dump truck..BTW it was in Weirton Steel. Timothy James Adam Enea I’ve never been to Zug Island but any blast furnace will have a gas cleaning and cooling system that processes the byproduct Blast Furnace Gas so that it can be used as a fuel in stoves, boilers, etc. This is done by water sprays into the gas stream, and then the water needs a recycle treatment plant to remove sludge and heat. Plants with multiple blast furnaces typically will have a common recycle water facility. |

|

| Jessica Van Gian posted The three blast furnaces of US Steel Great Lakes Works on Zug Island, Detroit, Michigan. Pig iron production ceased here in 2020, and the furnaces are now most likely awaiting demolition. |

|

| safe_image for Flickr Photo Second to last day of hot metal movements off of Zug island. |

Mark Jobin posted three photos with the comment: "National Steel Great Lakes Steel rebuilt Coke battery. 1st Push 1992."

|

| 1 |

|

| 2 |

|

| 3 |

James Vanderbeke posted 22 photos taken Oct 30, 2020. (Unfortunately, they are profile format. Laura described what is some of the photos. Some of the buildings are rather modern looking.)

US Steel bought this mill from National Steel.

Laura Mallory: On Zug Island - ironmaking - the Blast furnaces are shut down but the coke battery was purchased a few years ago by DTE and operates as ESS Coke. Boilerhouse and water treatment utilities operate to support the coke plant. The hot strip mill shut down this past summer, and probably will never run again. At the main plant, the pickle line, tandem mill(?), and continuous galvanizing line are still in operation.

Darrell Eaton: Where are the coils coming from? Gary or Mon Valley?

Laura Mallory: I'm not positive, but I believe they come from Gary. I think the only reason anything in the Great Lakes main plant is running is because they don't have galvanizing line capacity elsewhere that can produce the quality of Great Lake's CGL, which is now just 20 years old. When USS has galvanizing capacity (with product acceptable to automotive companies) they'll close it all down.

|

| safe_image for Steel mill at Zug Island still operating with a fraction of the workforce it once had Still operating, Pickler, Tandem mill, Skin Pass mill, Continuous Galvanizing Line and needed utilities. On Zug Island, the coke plant is running, but is operated by EES Coke. (DTE) |

|

| safe_image for Infamous 'Windsor Hum' finally dies down after U.S. Steel idles Zug Island plant The hum was below 30hz. It was felt rather than heard. It was caused by running the blast furnaces at a higher-than-normal capacity. "But recently, U.S. Steel was reprimanded by Michigan's Department of Environment after reportedly violating numerous emissions and pollution regulations between August 2017 and June 2019. The citations included exceeding visible emission limits, exceeding emissions of hydrochloric acid, degradation of local air quality, and failure to maintain and replace the facility's air filters, also known as 'scrubbers.' In May, the company was ordered to pay $79,227 directly to the state, as well as another $300,000 for a supplemental environment project in which the company is required to demolish one of Detroit's crumbling ice rinks and completely clean the area of contaminants." |

|

| Dale Groh posted This is a view of the Main Plant and many of the Finishing Facilities. The Detroit River is at the bottom of the photo and Windsor, Ontario, Canada would be behind the photographer. |

|

| 3D Satellite |

|

| Dale Groh posted This was part of a brochure they passed out years ago. It describes some of the history of Great Lakes Steel, under National Steel's control. |

|

| Dale Groh posted Another view of the Main Plant, as seen from the River view. Notice the Hot Metal bottles waiting to be dumped at the BOP shop. John Sheridan: I have a question? How long can the hot metal stay in the metal cars? Jonathan Carlson: John Sheridan , 16 to 24 hours before the iron would cool and harden. We use to throw Ferrum into the bottle cars once the bottles were filled. The Ferrum would crust up to keep the heat inside the bottles in case of any delays at the main plant. |

|

| Dale Groh posted Another view of the casters and several other building that are no longer in use. |

|

| Billy Bentley posted Zug Island Mi |

|

| Comments on a post |

Trent Pullou posted five photos with the comment: "A couple pictures from where i used to work. Great lakes works in detroit, the first is removing the top of 1 stove in 2018 second is a picture from the top of d4 the third is d4 popping a bleeder and the last 2 are from the top of B2. There was nothing quite like working on a blast furnace to say the least."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| See below |

|

| Comments on a post |

|

| safe_image for Mill workers steel themselves with large part of complex set to become history Ap4 20, 2020 [Why do corporations announce closures just before Christmas? Why can't they wait a month?] |

US Steel bought this mill from National Steel.

|

| INDUSTRIAL CULTURE & PHOTOGRAPHY posted Back in the glory days when Detroit was forging the United States. Great Lakes Steel Corporation, photo by Arthur Siegel, 1942 |

|

| Jeffery Todd posted DTE Energy's outbound coke field on Zug Island with USS-GLW's inoperable Blast Furnaces A & B in the background. John Travers: Why is the coke plant on Zug Island still in operation? Where is the finished coke being shipped to? Jeffery Todd: I'm not at liberty to say. EES has several customers. Guy Reph: DTE uses it to fuel their boilers. |

|

| Eric J Brown commented on Jeffery's post B Furnace, picture taken from the top of D Furnace at Zug Island! The Dirtiest square mile in the world!! |

|

| Kevin Nelson posted EDMUND FITZGERALD steel bulk freighter (U.S. 277437) built in 1958 at River Rouge, Michigan by the Great Lakes Engineering Works (Hull #301)for the Northwestern Mutual Insurance Co., Milwaukee, WI. and chartered by Columbia Transportation Division, Oglebay Norton Co. for 25 years: 711.2' x 75.1' x 33.4'; 13,632 GRT. She was the largest bulk carrier on the Lakes when launched. Bow thruster added in 1969 and converted to oil fuel and fitted with automated boiler controls Winter of 1971-72. Foundered in heavy weather with all 29 hands on November 10, 1975 in Lake Superior; 17 1/2 miles from Whitefish Point. She is shown here unloading at Great Lakes Steel on Zug Island October 26, 1975 - in a photograph which has been documented as the last photograph ever taken of "The Fitz" before her untimely loss on Lake Superior. She was bound again for Zug Island with another load of iron ore when she was lost. Photograph by Paul C. LaMarre, Jr. |

|

| Kevin Nelson posted Michigan Steel Works Great Lakes Steel National Steel Corp. These buildings are gone. Michigan Steel Works had an armor plate line. My father worked here for 2 or 3 years before returning to the main Great Lakes Steel location in Ecorse, Michigan. My first round of employment at Great Lakes Steel I was assigned there to tear out the old armor lines (1977-1978) Michigan Steel Works was located on Mill Street, in Ecorse, between W. Jefferson Avenue and the Ecorse River (Creek) |

|

| William Borg posted The now cold. Hot side of Uss Great Lakes works on Zug Island The coke ovens on the other end of the island are still going as DTE /operates them Very sad to see this place like this. [Per the comments, at least they are making some money because they are storing hopper cars on the high line.] |

|

| Kevin Nelson posted The now cold and silent blast furnaces of Great Lakes Works - Zug Island, as seen from the Gordie Howe International Crossing Bridge construction site in Windsor, Canada. #UnitedStatesSteel James Torgeson: Neat graphics. I never realized the new bridge was going to be so close to Zug Island. Dirk Graham: James Torgeson probably one of the reasons zug got shut down. It wouldn’t do to launch burning debris into vehicles on the bridge when the bleeders open. |

|

| This photo has been moved to "1914 DCAX+vehicles Zug Island Road Bridge (#141) over Rouge River at Detroit, MI." |

|

| Wade Klaffer commented on James comment Imagine crossing the bridge to this sight lol. This is B-2 furnace that the bridge is going to be very close to. |

|

| One of three added by Craig Hensley Photography to the album Boats of the Great Lakes M/V Sam Laud Tech: DJI Mavic Air 2s Date: 6/29/21 Location: Detroit, Michigan |

|

| Mike Delaney Consumers Power unloading at the Zug coal hopper at Great Lakes steel.. Hennepin was a regular here and so were a lot of B&C vessels. Whats kind of historic here is not just the boat but the hopper. Very few shots of the hopper. GLS historian wanted this shot for the hopper view. Mike Delaney posted The real Great lakes Steel Zug island Detroit 1976. Consumers power unloading into the coal hopper on the Detroit River face of the island. All long gone including the Great Lakes Steel tower on the right. D-4 furnace in the background. |

|

| David Bussell posted Zug Island, National Steel Corporation- Great Lakes at the confluence of the Detroit and Rouge Rivers. Aerial photo prior to 1936 (C3 Blast Furnace, not yet built). Bob Doherty: Look at the coal stain in the river. David Bussell: Bob Doherty no sea wall. |

|

| Josh Roach posted, cropped |

|

| Andrew Dean Aerial Photography posted Love this shot of the Alpena from 2023 - the flame from zug island makes it appear like she’s shooting flames from her stack! 😂 |

|

| Wade Klaffer posted, cropped New BOP vessel installed at USS Great Lakes Works to only be used for less than a year. Bradlee Gregory: It was a nice upgrade considering the suspension on the old vessel was broken. As we would rotate the vessel it would shift in the suspension and the whole second floor would jump. It was crazy. We shut it down numerous times. Then they replaced it and we ran it less then 500 heats. The other vessel barely had any brick left inside and they insisted we keep running the old vessel. While potentially having to spray the furnace numerous times a day. This vessel sat with a gas pipe waiting to be used. I never understood why we didn’t use it our last few weeks making steel. They wouldn’t allow anyone enough time to repair it properly. The last reline was also suppose to be a suspension upgrade to the plates. When they were told approximately how long it was gonna take to weld it on it was cancelled. We were surprised the brick never fell out after the reline. It wasn’t anyone’s fault but the company’s. Even BOP management wanted it fixed so we wouldn’t shut it down anymore. They also overhauled the Precip, which captures emissions from the vessels. It was done about the same time the vessel was swapped. Crazy amounts of money spent to just let it sit and do nothing. |

Bradlee provided the following three images as comments on his comment.

|

| 1 |

|

| 2 They drove it in on this. |

|

| 3 |

Charles Abar posted four images with the comment: "Michigan steel in Ecorse mi. And some pictures of National Steels Great lakes Div. In Ecorse mi."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

Charles Abar posted three images with the comment: "National Steel , Great Lakes Steel Ecorse, Mi."

|

| 1 |

|

| 2 Gary Yazel: Where's the safety equipment? |

|

| 3 |

|

| Screenshot (source) 80" Hot Strip Mill Richard Allison: I am from the hot end and no little at the HSM. I see your mill is continuous with no reversing. How many roughers do you have before the finishing stands? Dennis Smith: Richard Allison five roughers , seven finishing mills and three coilers. |

Boaz Price posted five photos with the comment: "Lifted and transported old BOP out and transported, lifted and set new one in on SPMTs transporter and gantries. US Steel Great Lakes probably 4 years ago."

|

| 1, cropped |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

| HSM. Just what I see from a quick look. |

|

| Fred Bultman posted The J R Sensibar unloading bug dust at the hopper at Great Lakes Steel, probably the summer of 1976. This run, bug dust from Toledo to Zug Island, was dreaded by everybody who worked on the self-unloaders in those days. I was on this run in the summer of 1977 on the John T Hutchinson, and I never wanted to see powdered coal again. Fred Bultman shared |

%20Fred%20Bultman%20-%20The%20J%20R%20Sensibar%20unloading%20bug%20dust%20at%20the%20hopper...%20_%20Faceb.png) |

| Comments on Fred's post |

%20Lake%20Boats%20No%20Longer%20With%20Us%20_%20Facebook%20-%20Personal%20-%20Microsoft%E2%80%8B%20Edge.png) | |

|

William Borg posted three photos with the comment: ""

|

| 1 |

|

| 2 |

|

| 3 |

|

| Mike Delaney posted Some questions for ex-Great Lakes Steel(Zug) guys. When was the last time the "A" furnace operated(the one to the left on furnace row [comments corrected: A on the right, B on the left and C would have been in the middle of the photo. D was by itself in the middle of the island.]). Second When did the "B" furnace last operate and when did the top get chopped off. I know the furnace stack sat there for years and then was removed not too long ago. Seeing snow on blast furnaces is a sad sight to say the least. One more. When was the drawbridge removed on the north side of the island. [Summarizing some answers: "A Furnace shut down in October 2001. Nothing to do with 9/11. The economy was already slow. Then, about 10 million was spent for repairs and #1 Stove rebuild. The furnace was never started back up. "; B2 shutdown summer of 2019 for an outage to put in a new dust catcher and a mini reline, but never started up; and D4 shutdown summer of 2020.] Tom Harvey: I didn't know that the north bridge was gone. That was the primary way onto and off the island for both cars and coke deliveries. [USS never operated the A furnace, they took off the top and put it on #4 at Gary.] Casey Whitson: A furnace got a reline in 1999 then A furnace was brought up to temp then sat idel for a few month eventually shutting down... Michael Dodson: I worked the A furnace rebuild in late 1997 and early 1998 and also did the stove rebuild in 2001 on A furnace. Boilermakers Local 169. [The 1997-98 rebuild must not have been very good if it lasted for only 3 years.] Ray Schloss: Mike Delaney was your picture recent? Wondering what the string of newer covered hoppers is for. |

Francesca Scott made four comments on Mike's post

|

| A-1 |

|

| C-3 |

|

| D-4 |

Kaye E. Barker unloads coal at Zug Island as tugs Wyoming and Wisconsin assist the Algoma Compass into the Rouge River.

Detroit, Michigan 10/28/2021

Danny Salisbury: In 2003 when U.S. Steel bought National Steel D-4 instantly became U.S. Steel’s most productive blast furnace per cubic foot of working hearth volume and B-2 Furnace was Number three so the question begs….what the hell happened???????? I might add that in 2003 at the time of the purchase the BOF or some call BOP (steelmaking) was the most productive in North America. Also in 2003 Great Lakes had the #1 slab quality of all of U.S. Steel when it was purchased from National. It doesn’t take a rocket scientist to figure out what the problem was and how Great Lakes became a shell of it’s former self. [This confirms that this plant used to be National.]

Tim Carden: Danny Salisbury Fred Harnac...thats what happened..

Matthew Peters: Whiz kid, bean counter management happened.

[Some more comments about other blast furnaces being killed by management.]

Scott Wilkins: What exactly is happening here? Fascinated with the furnaces and still learning how they work.

Kyle Orris: Scott Wilkins basically they are trying to get a final burn out the of the blast furnace. Trying to push as much iron as they can out before they shut the furnace down to be repaired or idled.

|

| Dennis DeBruler commented on Dawson's post Is this the "there" that I keep seeing in the comments? Dawson Parfrey: yessir |

|

| Zhee Fawzheea posted "Coal feeders on tip of coke ovens, Hanna furnaces of the Great Lakes Steel Corporation, Detroit, Michigan". Photographer: Arthur S. Siegel Date Created/Published: November 1942 Medium: 1 transparency: color. Reproduction Number: LC-DIG-fsac-1a35412 (digital file from original transparency) LC-USW361-808 (color film copy slide) Call Number: LC-USW36-808 [P&P] Repository: Library of Congress Prints and Photographs Division Washington, D.C. 20540 USA Tom Pickerill: The Larry ran on rails on top of ovens. Lidmen wore wooden shoes strapped to their boots. |

|

| Michael Kravochuck posted This was a GHH top at D4 furnace great lakes works US Steel. we rebuilt in the shop test ran it disassemed it then built it on the furnace top. |

|

| Craig Hensley Photography posted Shoving their cut into the yard on Zug Island. Notice the old Great Lakes Steel plant switcher at the bottom of the frame. https://www.craighensleyphotography.com/Railroad-Photography/i-ZjfD2bV/buy |

|

| Dennis DeBruler commented on Craig's post https://www.google.com/maps/@42.2870958,-83.1064488,213a,35y,260.53h,60.4t/data=!3m1!1e3 |

Christian Yops posted two photos with the comment: "#2 BOP vessel bull gear replacement USS Great Lakes Works."

|

| 1 |

|

| 2 |

|

| Steve Hermann commented on the above post That’s a 8’ ladder! |

Mark Jobin posted two photos with the comment: "1 Caster at Great Lakes Steel."

|

| 1 |

|

| 2 |

|

| Tim Bemis commented on Mark's post, cropped Back in the day - 1978 Bob Doherty: It was started in November 1977. |

Mark Jobin posted four photos with the comment: "National Steel Great Lakes Steel Start up of Billet Caster 1969."

Christian Yops: Mark Jobin what building was this in?

Verlin-Johnnie Bibee: Christian Yops Number 2 open hearth. By#1 bop.

Bob Doherty: Christian Yops, just east of the EAF in the pouring aisle.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Mark Jobin posted 80” Hot strip Mill at Great Lakes. Josephine Lily Brown posted 80” Hot strip Mill at Great Lakes Eric E. Peebles: Out of the three HSM's I've worked in, this one was my favorite. Great mill, and great people. Rex Raub: Eric E. Peebles most all HSMs are fantastic ! Did you retire yet ? Eric E. Peebles: Rex Raub I wish. Ten to fifteen for me (I'm 52).. I'm at Ford now. The 80" at USS was just a bigger version of the 56". Same machines, but five roughers vs two. United built. Everything I learned at the 56 (which you taught me a lot), I took to the 80. After a three-year stint in Alabama at a brand-new SMS HSM, I preferred the old United. Viktor Mácha: What a museum.. This beauty is still running? Shawn Greene: Viktor Mácha Shut down in 2020. Andrew Hastings: Viktor Mácha the 80” HSM in Granite City IL is still rolling for now… Danny Salisbury: Was #1 for slab quality for all of U.S. Steel when was purchased from National Steel. It didn’t take very long for U.S. Steel to wreck that along with everything else. If it ain’t broke don’t fix it, but nope, USS had to change it to THEIR way. 😬😢 Brian Olson: They only had 8,000 HP per mill stand which is on the low end for generation II hot mills. Still is is a better hot mill than the 80"mill at Irvin Works which is still running (for the time being). |

|

| Lane Anthony posted Great Lakes Steel D4 blast furnace |

|

| John LaMothe commented on Lake's post Very Last slab that will ever be ran at Great Lakes!!!! |

|

| Christian Mccreight commented on Lake's post |

|

| Ricky Renaldo Beasley commented on Lake's post |

|

| John LaMothe commented on Lake's post Last shut down!!!! |

|

| Ray Belcher commented on Lake's post I took this picture of the last sunrise that I would see over D4 on my last day February 22 , of 2020 when I retired with 44 years. |

|

| Lane Anthony posted Slab storage at Great Lakes Steel |

|

| 0:31 video #2BOP |

|

| Chuck Stephenson posted Steven Biars: I heard USS kept some of the old foundations from previous furnaces in place because of some crazy grandfathering thing if they ever wanted to build new units. I’ve never been to Zug, so it could just be a rumor. Jim Reynolds: Steel Mill in Cleveland did that , They dug up some old old concrete and welded new rebar to it and then built a $200 million Furnace and stoves on that old concrete and called it maintenance job - They had a track hoe digging around for three days in the dirt to find a chunk of concrete! Once it was found and welded to , they called it a "maintenance job" so all the union construction workers took a 25% cut in pay! |

|

| John LaMothe commented on Chuck's post Last slab to ever be casted!!! |

|

| Travis Irwin commented on Chuck's post, cropped Big modifications/upgrades, Aug 2019. Shortly before shutting down. |

|

| Brian Smith commented on Travis' comment, cropped |

|

| Matt J VanLuven commented on Chuck's post [A comment indicates Terex crawler. I don't know if this was previous work of if they are now dismantling something.] |

|

| Matt J VanLuven commented on Chuck's post |

|

| Eugene Martin posted |

|

| Andrew Severson posted Sole survivor, Cuyahoga(43) loads Coke at Zug Island 12/22/23. She is the last of the A1 Maritimers class, and oldest operating Canadian boat on the lakes. Robert Borg: Loading coke from DTE Coke batteries, going to Essar Algoma steel I Soo Ontario |

|

| Chris Bradley commented on Andrew's post |

|

| Phil Jad posted Zug Island Aerial view [According to some comments, finishing operations are still running in Ecorse.] Robert Borg: Steel comes in via rail from Gary Ind Works. They were also getting some steel from the Big River EAF mill in Arkansas however don’t know if that’s still happening or not. |

Michael Maitland posted 10 images with the comment: "Recent vacation to Detroit to see the sights past and present. Saved this map, that one of you posted, of the National Great Lake works and explored what I could. More questions then answers. Zug island 3 blast furnaces looked cold. The coke plant was active and quenching when I was there. A 20+ coil train came south from the hot mill area to the main complex. My question to the group- what is working here, could possibly increase production in the future. Where are they getting the raw steel if not Zug? (did not pass any no trespassing signs, so sorry for the poor photos.)"

Steve Treviño Sr.: We get our coils railed in from Gary Works and Pittsburgh. Only the finishing dept at the Main Plant is open. Pickler, Tandem, Box Anneal, Temper Mill, and the CGL. And shipping.

Dennis DeBruler: Thanks for labelling the photos.

Michael Maitland also posted with the same comment.

|

| 1 Thanks for whomever posted this map. |

|

| 2 Zug 3 blasts and coke |

|

| 3 Main complex |

|

| 4 Hot mill |

|

| 5 Ecorse plant. Couldn't find much on it other then it specialized in armor plating. Foundry and wire plant to the right. |

|

| 6 Zug |

|

| 7 Coke working, coil train headlight in the distance. |

|

| 8 Hot side |

|

| 9 Main complex |

|

| 10 Ecorse, Mill street, nothing left. |

Mark Jobin posted four photos with the comment: "Great Lakes Steel 2 Caster."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

I did not realize that it was a rather modern mill (the 1961 date). Or maybe that is the date for the 80" HSM and the works is a lot older than that.

|

| Jonell Pointer posted Last coil U.S. Steel . Great Lakes Works. 80” hot strip mill. "The mill of the future" Patrick N Johnston: At one time the hot mill held several World records |

|

| David Yanez posted Last few slabs going thru at the 80 hot mill. U.S STEEL in michigan. Was a great job. Miss being a roughing mill operator. loved that job. Now im praying cliffs dont do me dirty again like u.s steel did. Its turning a slab into a steel coil. Its called the finishing mill where it flattens and stretches it out to specific dimensions that is ordered. Its really hot coming into the rolling mill so yes its cooled down as it goes down the mill as its getting turned into a coil at the very end of the mill, where its rolled up into a coil. [Some comments point out that this mill is rolling from right to left.] |

0:26 video of "March 31, 2020 final blowdow D-4 furnace Zug Island" (Blast furnace is belching grey smoke.)

33 WWII era photos with some interesting comments

8 drone photos taken July 18, 2024.

No comments:

Post a Comment