There is also a steel mill near Hamilton, OH.

|

| Stelco Rod and Bar Hamilton posted Before 1907 - this is a photo of the FIRST Blast Furnace (built in 1895) at Huckleberry Point in Hamilton, Ontario, Canada. By 1910 it was taken over by the Steel Company of Canada (Stelco.) As new Furnaces were added, this one came to be known as "A" Furnace. Over its lifetime, this small Blast Furnace produced 5-3/4 MILLION Tons of Pig Iron. |

|

| Stelco Rod and Bar Hamilton posted 1951 Building Stelco's 4th Blast Furnace 'D' in Hamilton, Ontario, Canada. Operations started in 1952. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted This long shot was taken circa 1953. Compare it to my previous post to see the rapid development of the Stelco enterprise, otherwise known as the Steel Company of Canada, based in Hamilton, Ontario at the time. The bottom of the photo shows the Blast Furnaces / Coke Ovens / By-products areas. The foreground shows the expanded Ore Docks on the Western part of Stelco's property. Randal Reef was not much talked about at this time. You will notice that Stelco's NEW Main Offices are built but not fully completed. Almost the entire north part of the Brightside neighbourhood (North of Burlington Street) can be seen. Adjacent to the Manchester Gate can be seen Hamilton's Incinerator, which still operated into the 1960's, believe it or not. East of the Incinerator is one of the iconic Gas Holders, a perpetual symbol of the working class. Top left shows the property of HAMCO, a heavily polluted area eventually absorbed by Stelco. Hamco made Coke for domestic consumption and produced By-products as well. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted A closer look at the Stelco Lands in Hamilton, Ontario, Canada, circa 1987. The caster at the far back is so new that it shines in the bright sunlight. The first slab cast there was on August 25, 1987. To the left is the former International Harvester / J.I. Case property, and Dofasco is to the upper right of the photo. A small portion of Hamilton's Brightside neighbourhood is still visible in the bottom right. D Eric Davis shared |

|

| Hans Herres posted Stelco Hamilton 1952 ..picture from another site Stelco Rod and Bar Hamilton: Why aren't you saying what the other site is? What are you afraid of, Hans? |

|

| Stelco Rod and Bar Hamilton posted So, WHERE exactly is Max Aicher, North America? aka MANA ?? MANA is the former Stelco Bar Mill (aka #1 Bar Mill), in Hamilton, Ontario, which was sold to the German company by U.S. Steel 15 years ago. Max Aicher received substantial financial support from the Canadian Government and then subsequently shafted the employees that came with the sale by imposing a MULTI-YEAR LOCKOUT. The end result: lower benefits, lower pension, lower wages, and very low morale. Not surprisingly, a high worker turnover continues to this day. Broken promises with no net benefit to Canada. I've highlighted the MANA complex in green as it stands today. This company divested #3 Bloom Mill, which originally came with the sale. (Original photo by Hans Herres) Lido Cognigni: They hired "SCABS" to take over plant, something that could of been prevented, but thanks to MIKE HARRIS elimating the laws the company had a free hand , coupled with TONY "GAZEBO" CLEMENTS' s handy work the two decimated the top bar rolling mill in the world, it beat out every mill on this planet till 09, then it was destroyed, unforgiveable, i saw DOUG FORD there yesterday, he did not notice what happened to it, because no one would tell him the truth, i don't like saying this, but what harris and clements did the tarriffs might finish it off totally, and we will be losing another mill, in the city, i just hope it can be stopped, and it can be rebuilt and run with proper people in it , and it can be what it once was, only hope, but im not holding my breath. Raymond Mercuri: Remember which government at the time approved the sale to US Steel with a list of conditions that were never met or enforced. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted CORRECTION - the date of this photo is 1953 - not 1948 as previously posted (Thanks Mike) >> Stelco Blast Furnaces, Central Boiler Shop (CBS), #2 Ore Docks Bridge Crane in background and TWO houses (yes, houses!) inside the plant. This has to be one of my favourite archival photos of the Steel Company of Canada in Hamilton, Ontario. Source: Steel Company of Canada. [I guess I missed the previous post.] D Eric Davis shared Anthony Grandovic: At one time there were more than 200 blast furnaces operating in the states. Now there are about 20 Stelco Rod and Bar Hamilton posted again, unfortunately, he still has the wrong date. 1948 Stelco Hamilton, General View, Blast Furnaces and CBS - Central Boiler Shop with both full-size homes on Company Property, looking somewhat incongruous in an Industrial Environment. D Eric Davis shared Joe Borthwick: I love seeing the old photos. I poured over all the ones at the Hilton Works building. It’s hard to believe that the works manager and his family once lived just outside this photo. Sharlene Boehmfeld-Allaer: The best was when when I found the 4 foot bay water breach that they could not isolate during CCAA.. That was a long weekend. Tell Phil I’m waiting. |

|

| Stelco Rod and Bar Hamilton posted 1990's from Mike Woudstra. This view of Stelco's Coke Ovens / By-Products was taken from the top of D Blast Furnace in Hamilton, Ontario, Canada. D Eric Davis shared Allen Seth Johnson: Over 75% of that has been torn down |

|

| Stelco Rod and Bar Hamilton posted This circa 1953 photo was taken at the same time as my previous photo but is framed much closer than the previous long shot. It highlights the Blast Furnaces area of Stelco Hamilton as well as the Central Boiler Shop along with both of Stelco's main Offices on Wilcox Street, east side and west side. Another Gas Holder is featured on the far left, one of many that Stelco employed. Please add your comments, they are most welcome ... Earl Brown: That was my area, I worked electrical at all those furnaces, the coke ovens and boiler house. 'A' furnace had just been shut down 6 months before I got hired. I worked on the furnace relines of 'C' furnace, the converting of 'B' furnace from steam to electric and the reline converting 'D' furnace form a bell top furnace to a high pressure Paul Wurth top. The Marion shovel in the pit was electric at 600 volts 400 amp AC driving generators to run the equipment on it. Spent many nights repairing the cables required to run it. Mark Harvey: That would be B furnace on the north side of the boiler house. A furnace is West of B furnace. The salamander (iron nugget) for B furnace still sits in an open field where the furnace sat to this day. D furnace was built to the North of the old A furnace lot and E furnace was built waay North of the A furnace lot many years later. Coke ovens were built to the south of E furnace and those are the only one's that still operate today. |

|

| Stelco Rod and Bar Hamilton posted This must be "B" Blast Furnace at the Steel Company of Canada in Hamilton, Ontario. This photo was published in 1935 - the 25th Anniversary of the creation of the Steel Company of Canada. The Furnace looks too 'NEW' to be a contemporary photo - so they must have dug up an older photo to print in 'Stelco Flashes.' D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted March, 1944 - Steel Company of Canada Blast Furnace in Hamilton, Ontario sourced from the Archives of Canada. Glenn Gillis: Interesting transition point: that looks like the "modern" high dock that the loco is on, but in front is an old trestle, and the ore piles that disappeared when the "new dock" was built on the west side. Late 1940s? [The "March, 1944" date was added to the description after it was provided in a comment.] D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted I don't have a year for this Stelco Hamilton "C" Blast Furnace photo - but it looks brand new! (possibly 1941) If you walked into the plant from Wilcox Street, then you would definitely remember the "Safety Pays" underpass. Also notice the gas collector on the right. This scan came from one of Stelco's Merchant Products brochures. John DiFilippo: That furnace was a pleasure to operate. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1951 - Advertisement for a NEW Steel Company of Canada (Hamilton, Ontario) Blast Furnace "D " This Furnace started operating in 1952. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1956 - From a Steel Company of Canada (Hamilton, Ontario) promotional booklet. Stelco's "D" Blast Furnace. D Eric Davis shared |

Stelco Rod and Bar Hamilton posted four photos with the comment: "2001 - First of two sets from my good friend Russ Marini - the photographer who took these remarkable photos while aboard a Laker in Hamilton Bay (aka Burlington Bay.) Steel Company of Canada AND ArcelorMittal (previously Dofasco) Blast Furnaces in Hamilton, Ontario."

D Eric Davis shared

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Stelco Rod and Bar Hamilton posted Steel Company of Canada in Hamilton, Ontario. Stelco "D" Blast Furnace © Uwe Niggemeier. I think most will agree that Uwe Niggemeier has some of the BEST Stelco Hamilton photos, ever published ... D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted Steel Company of Canada in Hamilton, Ontario. Stelco "E" Blast Furnace © Uwe Niggemeier. I think most will agree that Uwe Niggemeier has some of the BEST Stelco Hamilton photos, ever published ... D Eric Davis shared |

#2 #2 |

| Stelco Rod and Bar Hamilton posted Stelco Bast Furnace > pre-1960. I scanned (and edited) this photo that appeared in one of the many Visitor Booklets that Stelco produced over the years ... Robbie Thompson: C Furnace D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1948 > Looking West over Stelco Blast Furnaces A and B to the Bay from the top of Blast Furnace C, more than a hundred and fifteen feet above the ground. Steel Company of Canada, Hamilton, Ontario. Source: Stelco Flashes. |

|

| Martel Gause posted 1990s Stelco E Blast Furnace in Hamilton, Ontario, Canada, from Mike Woudstra. |

|

| Stelco Rod and Bar Hamilton posted 1948 June > Stelco Blast Furnaces - photo taken from the roof of the New Main Office Building. Hamilton, Ontario, Canada. Source: Stelco Flashes. Brian Forsyth: Looks like before D furnace was built. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted Max Aicher, Stelco, ArcelorMittal. Photo from Hans Herres. D Eric Davis shared |

|

| Stelco Hamilton Works |

The mill is a lot bigger than the town of Nanticoke, ON. It looks like this mill is a relatively recent greenfield mill built further south of Hamilton so that the ore carriers did not have to waste time going through the locks of the Welland Canal.

|

| Stelco Lake Erie Works, the 3D view was not available |

Bubba Dubs posted five photos with the comment: "STELCO Lake Erie Works."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| Ricsan Kom posted |

|

| Stelco Rod and Bar Hamilton posted 1989 - as promised - here is Page 2 from the Mechanical Shops booklet. D Eric Davis shared ite plane for Stelco Hilton works in Hamilton ont. Sadly it's rapidly disappearing. |

|

| William Almas posted Hamilton Stelco bar mill and coil |

|

| Rick Guy Evans posted A couple of blast furnaces at Dofasco, with the Center mall barely visible in the foreground. Johny Cool: Actually more than a couple blast furnaces. Startling in the foreground that #2, 3 & #4 Furnaces all running. #1 was takin down a while ago. Jesse Linklater: I was running boiler #9 that crane is replacing the stack on in the background. Great place to work. |

|

| David Sanderson posted Dofasco Hamilton, Ontario |

|

| Stelco Rod and Bar Hamilton posted 1943 Electric Furnace Charge Side - Open Hearth - Stelco Hamilton. Source: Steel Company of Canada. Russ Marini: A very innovative forward thinking company of its day! [note the 1943 date] To bad the suits got a hold of it! Ted Lister: As I was told, Senior Steelmaking Supervisors didn’t buy in and undermined the project. D Eric Davis shared Found on another page. |

|

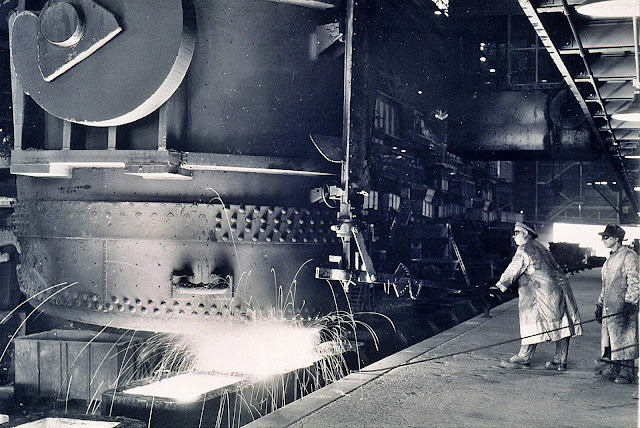

| Stelco Rod and Bar Hamilton posted From my friend Todd ... there are actually 3 men in this photo ... can someone explain what is going on in this photo - I think this is Stelco Hamilton? Comments please ... Geoff Palfrey: Manual tilt, 3 phase heroult type EAF, hoist driven electrode masts. Russ Marini: Tapping an electric arc furnace Could be the one installed by no.2 openhearth? If this is a stelco picture Any body else? George Hastings: In 1968 when I started Stelco had a Concast at the east end of 2OH….maybe #16 fce? D Eric Davis sharedFound on another page. |

|

| David Sanderson posted #4 Blast Furnace Dofasco Hamilton, Ontario |

|

| Hans Herres posted Picture of what is left of steel mills in Hamilton Ontario (unknown date and photographer) Tyler Hampson: Upper right is Dofasco and the picture barely shows half of what’s still there. |

Bob Bratina posted three photos with the comment: "Stelco D demolished-2004 but Lake Erie Works is getting an upgrade and reline to 'Smart' category."

Jason Spears Was this furnace in Hamilton or Nanticoke?

Bob BratinaAuthor Jason Spears this was in Hamilton. The Nanticoke furnace is getting a major overhaul right now. We have 3 more blast furnaces going in Hamilton at ArcelorMittal Dofasco. And another in Hamilton mothballed. That’s a lot of furnaces in our area. I love them.

Brad Maybee Bob Bratina only 2 running right now at Dofasco Hamilton one is idled.

Bob BratinaAuthor You’re right

|

| 1 |

|

| 2 Dennis DeBruler A rare view of the "guts" of a blast furnace. |

|

| 3 Glenn Gillis Stelco Furnace D - around 2004, Bob Bratina? Bob Bratina Glenn Gillis yes. I took the picture the day before they demolished it. Came down Sept 5/04. The demo guy told me the contract was for $1 dollar. They got the salvage. |

|

| Riscan Kom posted, cropped E furnace USSC (STELCO) dormant 2015 Bob Featherstone: Is there an operating blast furnace at Lake Erie Works? Brayden Rhora: Bob Featherstone yes the furnace at LEW is running. Relined the fall of 2020. Bob Featherstone: Do ore ships dock right there including 1,000 footers? Ryan Gowland: Bob Featherstone yup dock probably goes a km out into Lake Erie. |

|

| Tobyn Pearson commented on Riscan's post |

|

| Keith Ruitlidge posted Czarek Miłowski: Very short coke oven battery on the left side. Keith Rutlidge: Czarek Miłowski that is our #3 Coke plant. #1 is decommissioned and #2 still operating. Ryan Gowland: Czarek Miłowski 1 battery but 9m coke ovens so it pushes a lot of coke. Greg Bouchard: STELCO. My father worked there after WWII. He was a 2HI roller. Keith Rutlidge: Greg Bouchard not Stelco |

|

| Stelco Rod and Bar Hamilton posted 1948 Stelco Coke Ovens #4 Battery Coke Side (thanks Ron) > Hamilton, Ontario, Canada. D Eric Davis shared Bill 'Jules' Jula: having worked on the coke ovens at J & L in Aliquippa, PA, in the 60's, I NEVER remember them being THAT CLEAN!!!!! Ed DeLeeuw: You wanna see clean go to Dofasco. The regularly have men power washing the mill floors plus the oil cellars too! |

|

| Stelco Rod and Bar Hamilton posted 1952 - Steel Company of Canada, Hamilton, Ontario. NEW #4 Coke Oven Battery comes online. Source: Stelco Flashes. D Eric Davis shared Torn Ray shared |

%201952%20-%20Steel%20Company%20of%20Canada,...%20-%20Stelco%20Rod%20and%20Bar%20Hamilton%20_%20Facebook.png) |

| Comments on the above post |

|

| Stelco Rod and Bar Hamilton posted 1952 - Steel Company of Canada, Hamilton, Ontario. NEW #4 Coke Oven Battery comes online. Source: Stelco Flashes D Eric Davis shared Frank Kalasky: Are those Koppers ovens? Alan Telford: Wilputte Torn Ray shared |

|

| Stelco Rod and Bar Hamilton posted 1948 Stelco Coke Ovens #4 Battery Coke Side (thanks Ron) > Hamilton, Ontario, Canada. Glenn Gillis: The fellow at the very top of the stairway gives a pretty good indication of the size of these structures... Chris Tymchuk: My father started to work in the Coke Ovens in 1944. They gave him a pair of Wooden shoes to walk on top of the ovens. He looked at them , immediately quit and got a job at Harvester the same day. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1948 - Stelco Coke Ovens > Larry Car on #3 Battery > Hamilton, Ontario, Canada. (There's actually 3 men in this photo - can you find the 3rd??) Peggie Popowich: The 3rd Man on the right side, where clothes are. D Eric Davis shared Larry Haynes: Standing facing the Sandpipe, been there done that years ago ... |

|

| Stelco Rod and Bar Hamilton posted 1930's Steel Company of Canada, Hamilton, Ontario > Larry Car on Stelco's #2 Coke Oven Battery. Of the seven Coke Oven Batteries that Stelco had in operation over the years, only one is left today (#7 Battery.) D Eric Davis shared Tom Ray shared Daniel Lajambe: First battery I’ve seen with 4 charge holes!! |

|

| Stelco Rod and Bar Hamilton posted 1948 Steel Company of Canada, Hamilton, Ontario - Coke Ovens Top of #3 Battery. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1955 - Steel Company of Canada, Hamilton, Ontario > Coke Ovens with Anton Passchier displaying safety equipment that was prevalent at that time - including wooden clogs over his safety shoes. Source: Stelco Flashes. D Eric Davis shared Terry Gooch: That was a crazy job. First time on top the coke battery, smoke was everywhere and so thick I couldn’t see through it, and all I can hear is the charging car’s warning bell sounding as it was quickly approaching. Thankfully someone told me to hide between the stand pipes to keep from getting run over! 😳 Donald Datchuk: Terry Gooch i caught the pant leg of my "fire retardant" greens on fire when I stepped between the stand pipes for the Larry car to unload the charge. Someone left an inspection cap off&I was standing almost over the hole. I was also stuck there until the Larry car finished. As soon as the car cleared, I ran downstairs into the locker room&stuck my foot&leg into the trough sink&turned on the water. My 'greens', my blue jeans,my long underwear&2 pairs of socks kept me from serous injury. |

|

| Stelco Rod and Bar Hamilton posted 1948 Steel Company of Canada, Hamilton, Ontario - Coke Ovens Push side of #3 Battery. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1948 Steel Company of Canada, Hamilton, Ontario - Coke Ovens Pushing Coke on #3 Battery. D Eric Davis shared Michael Connors: That’s #1 Coke plant at Dofasco. I worked there in the early 2000s before it closed a few years later. Tom Ray shared |

%20Coking%20plants%20_%20Facebook.png) |

| Comments on Tom's share |

|

| Stelco Rod and Bar Hamilton posted 1948 > Steel Company of Canada Coke Ovens in Hamilton, Ontario. This photo shows a recently constructed Coke Ovens Battery at Hilton Works. Source: Stelco Flashes. |

|

| The Beauty of Steel Project posted The last weeks/days of Stelco Hamilton blast furnace, once the most efficient lady in Canada. The mill was cold since 2010, now under demolition. The slow end of blast furnace era. Thanks to my friend Michael Hrysko for this great archive shot. |

|

| Comments on the The Beauty of Steel Project post |

Stelco was founded in 1910 and was bought by US Steel in 2010 and is renamed US Steel Canada. Dofasco was founded in 1920 as a steel casting company and bought by Arcelor in 2006. "1945: With the end of the Second World War, Hamilton's mills produce about half of Canada's steel. 1954: Dofasco becomes the first steel company in North America to begin using a basic oxygen furnace, a more efficient way of making steel than the traditional open hearth method. Stelco remains committed to open hearth technology until the late 1960s. The same holds for the adoption of continuous casting technology. 1981: Stelco opens its new $800-million Lake Erie Works in Nanticoke, just as domestic demand for steel falls sharply." In general, it appears that Dofasco was quick to modernize and Stelco was slow. And the two companies also had different relations with unions. [TheSpec]

The fifties represented a time of rapid expansion for Dofasco. In 1950, engineers reclaimed land from Hamilton’s Bay, and in 1951 the site welcomed its first blast furnace and coke plant. In 1954, Dofasco was the first company in North America to adopt a basic oxygen furnace, and just a year later management established the Research and Development department to continue inventing new steels and technologies. [Dafasco]Stelco is the current name for The Steel Company of Canada, which was formed "in 1910 via the merger of Montreal Rolling Mills, the Hamilton Steel and Iron Company, and a handful of secondary companies located from Gananoque to Brantford." [stelco]

|

| Leonardo Labarbera posted Original picture of dofasco hamilton Wow! Just one battery! Later called #2 battery after additional battery’s added on either side of it. I cant remember exact year but the first coke battery and #1 byproducts was built in early 1950’s... i want to say 1953. |

|

| Charging the BOF at Lake Erie Works |

|

| David Walker posted Stelco, Lake Erie Works, months after star-up 1980/81. Still producing today. The Blast Furnace was relined in 2020. Coke Ovens Overhaul still in progress. Makes fantastic view at night. Philip Pickles: That coke oven rebuild is way over the original estimated cost.. it has resulted in a squeeze on the Hamilton maintenance budget. |

|

| Micahael Hrysko posted Looking eastwards .... Dofasco ., Bayfront area complex |

Mercedez Andrade posted three photos with the comment:

dafasco HamiltonEdit to addUPDATE: Many people shared pics of horrible emissions coming from ArcelorMittal Dofasco on afternoon of Nov. 14. The company sent an email out to Community Liaison Committee members with some details about what happened. Here is the text of that message:Dear CLC Members,There was an incident at the company’s No.2 Caster this afternoon at 1:22 p.m. The caster is where liquid steel is cast into slabs. There was a malfunction in the transfer of the liquid steel into the caster, causing a spill. The area is controlled and secure as of approximately 2:25 p.m.Fortunately, there are no injuries as employees are not allowed in the area for safety reasons.However, the incident resulted in a significant visible emission, likely due to both fire and contact between the liquid steel and water. The company’s Fire Department responded and managed the incident. Hamilton fire also attended for support.The Ontario Ministry of Environment, Parks and Conservation’s Spills Action Centre has been alerted as required.Our teams are on site investigating and further information will be provided if and when available.Best regards,John Lundrigan | General Manager / Director, EnvironmentArcelorMittal DofascoEnvironment Department | Box 2460, 1330 Burlington St. E.Hamilton, Ontario L8N 3J5T 905-548-7200 x6100 | F 905-548-7000 | www.arcelormittal.com | http://dofasco.arcelormittal.comClose your windows, stay inside. Dofasco fire smoke coming your way.

Mike Stamant shared

Mike McTigue: Looks like they did the right thing and got the ladle rotated out and limited damage to the caster.

Rob Kirton: Are they Mittal’s only remaining North American property?

Michael Green: I work about 2 miles down from Dofasco, and its an Arcelor Mittal Long Carbon. We do wire.

Dennis DeBruler: They kept the joint venture in Calvert, AL. And the R&D office in West Chicago.

[The comments indicate the floors are sand to simplify cleanup of the solidified iron. There is a consensus that it was a ladle gate failure.]

|

| 1 |

|

| 2 |

|

| 3 |

|

| Debbie Matthews posted Dofasco Steel - Hamilton, ON. In the summer of 2007, Dofasco 416 locomotive pulls 2 loaded hot metal cars from the east side of Number 2 Blast Furnace. Note locomotive is operated by remote control. Jason Spears: Walked down that road many times going between #1 Byproducts and 2/3 BP. Debbie Matthews: Long walk from Gate 10 to #4 BF! |

|

| Debbie Matthews posted Dofasco Steel, Hamilton, ON - Ore dock in the summer of 2000 Alistair LaForme: That clam is hauling. John W. Bousfield: Memories of changing buckets from ore to coal. |

Rick Guy Evans posted three photos with the comment: "In Hamilton, two steel companies dominate the harbour...this is the other, with Dofasco's iron ore dock with maintenance being done on the ore bridge."

John Keane: But only one produces any more . Stelco just does galvanizing now of outside sourced.

Mike Chechalk: John Keane all the steel that goes through our Z-line comes from LEW.

James Torgeson: Dofasco is one of the few places remaining where a straight-decker can be unloaded.

|

| 1 |

|

| 2 |

|

| 3 |

|

| Rick Guy Evans posted "E" blast furnace sits idle; the last campaign was in '97. Its fate is still unknown. In its day, it produced 400+tons of molten iron in a cast. Mike Chechalk: She set a lot of company records. She had a great life. She gave us a lot of good times and many a bad nights. She made us do things to make sure she lived for another day. Rick Guy Evans: Mike Chechalk in the late '90s, I applied to the "Blower" position on "D" fce(now gone:( )...I spent time there and found that these fce were truly "alive", especially when one "slipped" (scared the beans out of me!) Everyone had to work together, as you were working on a bomb! Eventually, my boss would not release me to change departments. Philip Pickles: US Steal tried unsuccessfully to take our pension money but they did succeed in taking our orders and shutting down the blast furnace .. Larry Hildreth: Not 97, shut down for second (final) time in 2010. Mike Chechalk: Rick Guy Evans During the ‘91 reline stave cooling was installed and the plate cooling was removed. The bricking you refer to is a blow in lining so the stave don’t get damaged during the start up. The ‘97 reline was upgraded to many of the external components of the stoves, stave cooling system, gas cleaning and stock shed. There were also up grades to computer soft and hard ware. The system was also updated so operators could view the operations from other locations in Hilton Works. John Gregory Pittman: It’s being demolished it was the most advanced blast furnace in North America. PCI ( pulverized coke injection with oxygen injection ) Paul Worth top / automated shed / Radarokie Technology from Belgium to monitor the amount of material in furnace to estimate yield / slag popcorn maker a aggregate for cement . Very sad nation wrecking |

|

| Rick Guy Evans posted Yet another view of Hilton Works "E" fce from the water. |

|

| Comments on Rick's post |

|

| Rick Guy Evans posted The ironmaking side of Hilton works, with E furnace down and the coke ovens still operating. A crisp day in November, with Aldershot/Burlington in the background just across Hamilton Harbour. Taken from atop the Escarpment (what Hamiltonians refer to as "the mountain"!) John Keane: Soon to be demolished. Except for galvanize. And coke |

|

| Rick Guy Evans posted The blue buildings comprise the Cold Rolling & Coating mills in Hilton Works. The tall green box-like tower is #3 Pickle line: 7 stories of vertical acid tower. The temper mill, 4-stand and galv line are one of a few of the mills that still operate in the Cold mill. In the background, is #3 Bloom mill. Mike Chechalk: Is that Acid Regen (Red Hill) in front of the mill. We on the west side of the plant called it Red HILL. Rick Guy Evans: Mike Chechalk to the extreme left(barely noticable)...we in the Pickle lines called it the red barn...horrible place to work, but boy did it make money! Adam Pereira: 3 b&b is owned by mana, they are currently tearing out the mill. Can’t forget Stelco just installed a new batch anneal line at the south end of their cold rolling 4 stand about 2 years ago. All decommissioned mills are being torn down. Joe Grazulis: Vertical acid tower? I wonder how that works. Rick Guy Evans: Joe Grazulis it works well as long as it is maintained with great care...acid is very unforgiving to steel! |

|

| Stelco Rod and Bar Hamilton posted 1949 Stelco Hamilton, Continuous Pickle Line, Entry End, Cold Reduction Mill Tom Downton: I worked on that line in 1958 and 59 I did the looping pit observer and the job called feeder b. also worked on exit end as the upcoiler operator, I banded up the coil and marked the information in the eye of the coil. D Eric Davis shared Joe Borthwick: I worked on building repairs there while both lines were running. Everything was corroded. The acid destroys everything. Acid Regen next door was worse. Everything was covered with red. Graham Whitfield: Joe Borthwick: You are totally correct about acid corrosion Joe. A friend of mine worked in the Pickle Line in the early 70’s at British Steel Llanwern Works. I worked in the Slabbing Mill and went down to see him one night shift when we had a breakdown. My eyes were stinging from the acid fumes and you could almost taste the corrosive atmosphere. Many of the Operators had black teeth, evidently the acid fumes are away the tooth enamel. I was glad to retreat back to my place of work. |

|

| Comments on the above post |

|

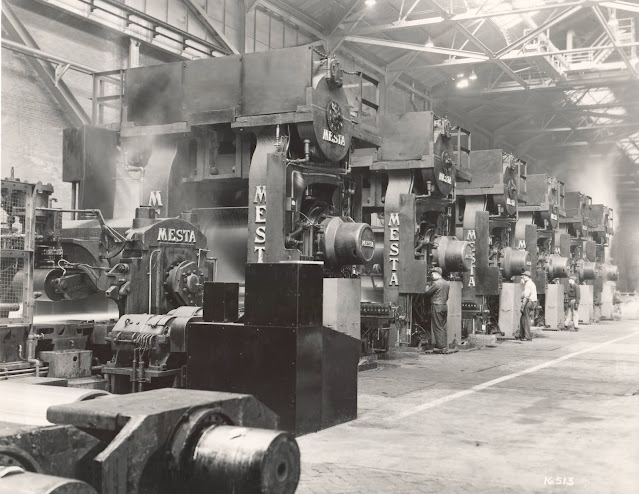

| Rick Guy Evans posted Speaking of Mesta: 56" hot strip 1946 6-stand Hilton Works...this is my best pic of this moth-balled relic! Pat McCon: Back when there was an operator at every stand! Jeff Sherrill: This is a great picture. Now. In layman’s terms, please explain what goes on. Simple is better… Rick Guy Evans: Jeff Sherrill Oh boy...the short version: 1 1/4" thick steel strip enters 1st stand; is compressed and fed into #2 stand where is compressed more and pulled into #3 stand &is compressed again and pulled through faster until the 6th stand...strip can be about .075" to .057" (thereabouts) and comes out flying to the upcoiler to make a coil of strip. That's the simple explanation...but a lot of things are going on all at the same time. When I left this mill in 2000, it had already been upgraded to have only a couple of operators up in a pulpit, instead of a roller at each roll stand when it was new. Rick Guy Evans: Jeff Sherrill oh yeah: this pic shows #6 stand, which is the exit side of the travel of steel strip, so moving right to left. This is vintage 1933 mill stands: nuclear-proof! Jerry Lacy: Michael Ray Watkins is the slab still 8+inches thick when it goes into these stands or is there an intermediate process? Rick Guy Evans: Jerry Lacy yeah...the rougher, the 110" mill and an edger takes the slab down from about 8-9" to 1 1/4"...then into the coilbox , crop shear and then the 1st mill stand. Phil Jadlowiec: Hamilton Ontario Stelco ? Rick Guy Evans: Phil Jadlowiec yes sir! Dave Demharter: This is the exactly same rolling mill at our plant. (Allegheny Ludlum). Then they built a new mill and dismantled this one. Michael Watchorn: We had a 6 stand in Lorain rolled rounds and squares our stands were all made by united. Rick Guy Evans: Michael Watchorn yeah...United and Dominion were other mill-stand producers. |

|

| Stelco Rod and Bar Hamilton posted 1965 Stelco's NEW 4-high heavy Plate Mill in Hamilton, Ontario, Canada. Source: Stelco Flashes. Mark Cia: My observation only; One of Stelco’s biggest blunders at the time. It was a huge money pit that kept draining the company. The sad part of it all was Stelco ended up losing an entire Plate Mill. Stelco was then forced to finish the project using their own finances after Tippins went belly-up. That fiasco was to me a testament to keeping things simple. The way I understood it at the time was to develop a mill that could remove the Camber shape of the plate. Unfortunately it was too complicated because of the close proximity to the Rolls. ( cobbles, fires ) .. The Steckel mill process is a method for hot-rolling steel that involves heating a steel slab and passing it back and forth through a reversing mill. After each pass, the strip is coiled into a heated furnace-coiler on either side of the mill for temperature control before being sent back through the rollers..I recalled a degree of heartfelt sadness when the mill was dismantled and sent to India. I'm sure those that worked there in the Plate Mill and experienced that era have many stories to tell. Overall Stelco managed to survive thank goodness 👍😊 *Note that the picture shows the 2 hi mill and the 4 hi mill is downstream. Fred Mancini: Was that the 148 inch Stelco Rod and Bar Hamilton: Fred Mancini Yes D Eric Davis shared |

Stelco Rod and Bar Hamilton posted four photos with the comment: "April 2003 - Stelco's 148 Inch Plate Mill in Hamilton, Ontario, Canada. Thanks to Terry Chewka, I think these photos were taken when the last slab was rolled before they shut it down for good. Everything has been bulldozed, now. Photos courtesy of my friend Steve Bradshaw. (Part 1)"

D Eric Davis shared

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Rick Guy Evans posted, cropped One of the trinkets (coaster) that Hilton Works handed out to all the plant workers when the Continuous Caster's first successful pour of first slab on Aug25,'87.(my 21st birthday and 10 yrs in Stelco!) Today [Nov 15, 2021], they are razing the caster to the ground: 34 years later. |

|

| Rick Guy Evans posted Sadly, I have only one pic of Stelco's last two blast fces together: "E" on the left and "D" on the right. They are both gone now. |

|

| Ryan Cranston commented on Rick's post [According to the comments, E was scheduled to come down Dec 8, 2021] Rick Guy Evans: Ryan Cranston Wow! Do you know the date D came down? Terry MacDougall: Rick Guy Evans "D" came down just after Stelco first went into bankruptcy protection. The market had turned around and there was a shortage of steel supply. I heard that Dofasco (not sure if it was still called Dofasco) wanted to rent and run "D". Stelco said no that we are tearing it down - this in bankruptcy protection and our wonderful government allowed the demolition to still happen."D" Furnace was in excellent condition, many, many years away from a reline. It was just banked and could have very easily been put ahead. "D" was the better furnace. "E" only out-produced it, due to having the ability to continuously cast, as "E" had two cast houses. "D" was designed with two cast houses in mind. It already possessed the second cast hole; if they'd have built the second cast house, "D" Furnace would have out-produced "E" Furnace again. BTW, just as an interesting point, and proof of God... I fell off of the top of "D" Furnace when I was much younger. We were packing the bleeders - Jay Joseph and myself. Jay was tapping a chisel, under the baked asbestos packing, while I was pulling on the packing. Jay had the chisel on a bad angle and cut through the packing that I was pulling on. I fell straight back over the side of the furnace - no safety harnesses used in those days. I was standing straight up when I went over. This is one of the things that saved me. Three levels down, the furnace widened out a bit, and my boot heal hit the handrail for the walkway. I slid down legs rubbing hard on the inside of the handrail onto the walkway. A sixteenth inch farther out, and the handrail would have slipped from the heal of my boot onto my boot sole, and I would have slipped to the outside of the handrail. The next stop would have been a smoldering red hot slag pit. This would not have been my preferred way of leaving this life! LOL When I climbed back up to the bleeder platform packing still in my hand, our Forman Gerry Boyd and Jay Joseph were still frozen and white in shock. I was the one, who fell and they were the ones, who were injured. It took me a while to get them to snap out of it. All they could see was me disappearing over the side of the furnace. Jay could not go back on top of the furnaces again. I don't think that he ever did. Me - no problem. LOL Harold L. Orr: What is the round tank? ShawnandDebby Arlow: Harold L. Orr I believe they are Grain storage for Bunge. [Parrish and Heimbecker, Limited] |

|

| Rick Guy Evans posted A view of the skip hoist and dust catcher on "D" blast fce, circa '94/''95 at Hilton Works. |

|

| Cody Lee commented on Rick's post For anybody not familiar with Stelco's furnace setup, a map. |

|

| Cody Lee commented on Rick's post From a fly over this summer, 2021. Taken by me. |

|

| Mike Schymkiw posted ALGOMARINE at Dofasco, Port of Hamilton, December 2010... |

|

| Eliya Radusin posted One of the old pictures at Dofasco of our Open Hearth. |

|

| Andy Puskas commented on a post My Dad as a Rougher at the 20" Mill at Stelco in Hamilton, Ontario. Did that job for 44 1/2 years. That picture of my Dad was taken in the '80's. No face protection, no hearing protection, no gloves. It was another world! |

|

| Stelco Rod and Bar Hamilton posted Memories of the 20 Inch Mill - Steel Company of Canada, Hamilton, Ontario. Lots of action going on in this wide photo, with the Hot bed behind the Rolling Mill. The photographer is facing West towards the end of the Mill. Bob Exley: These downside roughers amazed me! While gripping, turning and balancing on its edge they would walk backwards THEN forwards BETWEEN the spinning floor rolls!! D Eric Davis shared Tim Kilboy: Great pic, was this a steam driven mill? Looks like a 1900 era configuration. |

|

| Stelco Rod and Bar Hamilton posted Pouring Ingots at the Steel Company of Canada in Hamilton, Ontario, Canada. This is an actual photo - not a drawing. Source is a Stelco Sales Brochure, circa 1966, called "Merchant Products" featuring NAILS and other products. D Eric Davis shared |

|

| Mike Schreiber posted Are blooms same as ingots? [No. Ingots used to be rolled into blooms in a blooming mill before they invented how to continuous cast blooms. "A typical cross-section of a bloom as 'square or slightly oblong mostly in the range of 6" by 6" to 12" x 12".'" Before continuous casting, blooms where then rolled into billets. Now, if the smaller cross sections of a billet is needed, they cast that cross-section instead of a bloom cross-section. At USS, at least, the difference between a bloom and a billet was 36 square inches. An ingot could also be rolled into a slab which could proceed to heavy plate or coiled strips.] Carl Jacobson: This photo is of the ingot mould being stripped off a drag of steel ingots.These are relatively small ingots and not too wide, they are probably going to be rolled into bars. They would have been reheated in a Soaking Pit and then rolled by a Blooming Mill. If the finished bar was 36 square inches on the end, it would be a Bloom. At the USS plant where I worked, the Bloom could continue on down the roller table without reheating and be rolled into smaller bars by another rolling process called a Billet Mill. The smaller bars, under 36 square inches on the end are called Billets. Many mills had to reheat the Blooms to roll them into Billets.Wider ingots would usually rolled by the Blooming Mill into slabs. Those slabs are technically also Blooms, because they are over 36 square inches on the end. Usually the slabs would be reheated and rolled into coils on a Hot Strip Mill. Lee Bradshaw: "bloom" is a size: Wire - narrow strip Rod - coil Bar - sheet Billet - sheet Bloom - slab Ingot I think 🤔 |

|

| Stelco Rod and Bar Hamilton posted 1940's - Coke Ovens at the Steel Company of Canada in Hamilton, Ontario, Canada. I believe this photo shows a TOUR of visitors witnessing the process of making top-quality Metallurgical Coke required to make Iron in Stelco's Blast Furnaces ... Source: Steel Company of Canada. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1942 - Steel Company of Canada, Hamilton Ontario. Coke Ovens #2 Battery on the quench side. Over the years, Stelco had up to 7 Coke Batteries. #1 Battery was dismantled in 1953. #2 Battery was dismantled in 1951. Today, only #7 Battery remains. Source: Steel Company of Canada. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted Hamilton, Ontario, Canada > Stelco # 2 Rod Mill Coil Compactor / Upender. Photo courtesy of TF E Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1942 - This archival image highlights Stelco's 110 Inch Plate Mill, where hydraulic cylinders ensure secure steel plate positioning during shearing. (Thank you, Helmut) William Harris: Last stop before heading for the scales & then the shipping floor. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1920's Steel Company of Canada - charging molten iron D Eric Davis shared Brian Bojin: Looks like a number one OH because of the low sills |

|

| Stelco Rod and Bar Hamilton posted No. 2 Open Hearth - Pouring side of a 180 Ton OH Furnace - Steel Company of Canada, Hamilton Works. Steve McQuade: Never seen 2 stopper rods in any ladle in #2 open hearth . This has to be 35 furnace in # 3 open hearth. Remember picking up those ladies ladles with the 525 crane. Brian Paul: Steve McQuade You are correct. The only 2 stopper ladles were only for 35 Furnace, I believe. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted This Stelco No. 3 Open Hearth photo was published in 'Stelco Flashes' in the 1971 Jan-Feb Issue. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1953 Stelco's New #3 Open Hearth, Hamilton, Ontario, Canada. Wayne Huggins: Is that #31,#32 & #33 furnaces? John Goodale: That would have been nice see when everything was nice and square and level. Nice picture. D Eric Davis shared Brian Bojin: Hard to tell but that looks like 34 furnace. Awesome picture |

|

| Stelco Rod and Bar Hamilton posted Steve Catman worked in Stelco's BOF and # 3 Open Hearth / Mould Shop between 1977 and 1988. He sent us these previously unpublished photos ... D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1976 - Stelco Hamilton BOF south pouring deck and #27 crane. Photo courtesy of Wayne Huggins. D Eric Davis shared Kyle Olender: What year was the caster installed in hamilton Cody Lee: Kyle Olender late 80's. |

|

| Stelco Rod and Bar Hamilton posted 1954 - Stelco's # 3 Open Hearth BEFORE pollution control precipitators were installed. D Eric Davis shared Peter Hess: The OH was using a wet scrubber to abate the particulate matter. |

|

| Stelco Rod and Bar Hamilton posted Not sure where I got this photo ... is that a double stopper? is this Stelco' Glen Graham: I think maybe #2 open hearth 3OH ladle Slag runners were on other side of ladle also only 35FCE ladles had 2 stoppers in 3OH and that’s no 35FCEs No. 3 Open Hearth? Your comments are MOST welcome ... [Several comments say #35. One comment says #3 open hearth.] Russ Marini: Glen Graham what’s the purpose of two stoppers? Control, flow, safety????? Mike Stephenson: Russ Marini empty the ladle quickly. Use to use double stopper at Dofasco Foundry when casting Rail locomotive frames. |

|

Stelco Rod and Bar Hamilton posted 1955 - Stelco's #3 Open Hearth - teeming ingots - Compare this with the preceeding photo. D Eric Davis shared Bob Newman: It's so clean that must of been the first pour |

|

| Stelco Rod and Bar Hamilton posted 1920's - Steel Company of Canada - pouring ingots in No. 1 Open Hearth D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1931 Steel Company of Canada, Hamilton Works, No. 1 Open Hearth. This photo courtesy of Graham Carroll. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted This is Hamilton, Ontario for sure - but is it Stelco or Dofasco? Source is Old Ontario Series. Your comments only make this page BETTER - thank you ... [The consensus is #2 OH in Stelco.] D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted No. 1 OR No. 2 Open Hearth at Stelco Hamilton? Which one is it? (From my friend Graham Carroll.) Steve McQuade: #2 OH 165 crane D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1950's Stelco's # 3 Open Hearth - teeming ingots. Your comments or observations are ALWAYS most welcome ... (thanks Wayne) Bernard Parro: My only fear was a running stopper. Wayne Huggins: #3 OH ? I remember these Treadwell ladles, some made it to the BOF, I remember burning scrap from the C hooks and inside when they were being rebricked, also changing and rebuilding the harnesses that controlled the stopper. Kyle Olender: Looks like a high quality asbestos coat the guys are wearing. Stelco Rod and Bar Hamilton: Kyle Olender there was LOTS of asbestos safety gloves, coats etc ... back when I started, Kyle ... D Eric Davis shared |

%20Steel%20Mill%20Pictorial%20_%20From%20another%20group.%20_%20Facebook.png) |

| Comments on Eric's share This is the best explanation I have seen when they can't stop the flow of metal between ingot pours. |

|

| Stelco Rod and Bar Hamilton posted 1939 - Stelco's # 2 Open Hearth - teeming ingots > your comments and / or observations are always most welcome ... Bryan Black: Operated both 20 & 27 in both #2 OH & BOF [Some comments talk about mechanical vs. hydraulic stoppers.] D Eric Davis shared |

|

Stelco Rod and Bar Hamilton posted 1930's Stelco Open Hearth - your comments and / or observations are always most welcome ... D Eric Davis shared |

|

Stelco Rod and Bar Hamilton posted MORE Stelco Open Hearth photos D Eric Davis shared |

|

Stelco Rod and Bar Hamilton posted MORE Stelco Open Hearth photos D Eric Davis shared Mark Adamcik: It looks like the ingot teeming track is standard gauge. |

|

| Bryce Ford posted Got to take a picture of the G3 Marquis docked at Dofasco in Hamilton, ON being offloaded by their ore bridges. Offloading Iron ore most likely from Superior Wisconsin. Darryl Harper: This ship is primarily a grain carrier from Thunder Bay to the Gulf of St Lawrence. These flat decker grain carriers often back haul iron ore from the Gulf- think usually Quebec. As a consequence Hamilton is the only port with steel plants that can unload straight deckers. The Ryerson made trips there until 2009 when one of the blast furnaces closed. Self unloaders occasionally make trips to Hamilton with ore from Lake Superior lakehead ports. |

%20Ship%20Junkies%20-%20Lakes,%20Locks%20&%20Rivers%20(LL&R)%20_%20Got%20to%20take%20a%20picture%20of%20the%20.png) |

| Comments on Bryce's post |

D Eric Davis posted five photos of a mechanical press in National Steel Car which was owned by Dofasco in Hamilton, ON.

(new window)

(new window) This video consists of a bunch of close up scenes that don't mean much to me. But at 1:55 it shows the pusher shoving the contents of a camber to the other side. And at 2:25 it shows the door of a camber being closed. I can't believe they didn't show the coke coming out of a chamber and falling into the hot car. At 2:37 we see the coke in a hot car on the way to the quenching tower, and at 2:39 we see the steam coming out of the tower at the start of a quench

(new window) Skip the first minute, it is just intro. The #3 coke plant is at 6:30. (source)

(new window) This video consists of a bunch of close up scenes that don't mean much to me. But at 1:55 it shows the pusher shoving the contents of a camber to the other side. And at 2:25 it shows the door of a camber being closed. I can't believe they didn't show the coke coming out of a chamber and falling into the hot car. At 2:37 we see the coke in a hot car on the way to the quenching tower, and at 2:39 we see the steam coming out of the tower at the start of a quench

(new window) Skip the first minute, it is just intro. The #3 coke plant is at 6:30. (source)

|

| safe_image for 2:17 YouTube Video safe_image for Controlled explosion demolishes Stelco’s last blast furnace |

I chose this view because we can still see the dock side equipment. Notice the unloading boom has already moved towards the unloading position.

|

| 5:49 video @ 2:17 EDWIN H. GOTT - ARRIVAL /TACONITE OFFLOAD - NANTICOKE, ONTARIO (MAY 25/2021) |

|

| This safe_image is around 4:53 |

|

| Stelco Rod and Bar Hamilton posted Late 1940's > early 1950's Boat Salvage at the Steel Company of Canada, Hamilton, Ontario. Many ships were towed onto Stelco property and dismantled for the sole purpose of feeding the hungry Open Hearth furnaces. Ted Lister: A lot of those ships were decommissioned from our Navy. D Eric Davis shared Direct to the mill. |

|

| Antho Bdyt posted A Stelco Steel plant in Hamilton in 1973. Ed Hill: Is that a rod mill? Worked in one at US Steel. David Warner posted with the same comment. |

Stelco Rod and Bar Hamilton posted five photos with the comment: "Undated photos from the Billet Yard/unscrambler/conveyor line at Stelco's # 2 Rod Mill in Hamilton, Ontario, Canada. Various Sources."

D Eric Davis shared

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| Stelco Rod and Bar Hamilton posted I believe we're back to 1947 in this Stelco Reinforcing Dept. photo taken at Hilton Works in Hamilton, Ontario. This was the Original Reinforcing Dept. about 15 years before it was moved to Hamilton's East end. I believe the photographer is facing North in this case, with the 12-10 Mill to the right. There are two machines in this photo, used for shearing to length and straightening, I believe. Source: Stelco Flashes. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted I believe we're back to 1947 in this Stelco Reinforcing Dept. photo taken at Hilton Works in Hamilton, Ontario. This was the Original Reinforcing Dept. about 15 years before it was moved to Hamilton's East end. I believe the photographer is facing North in this case, with the Rod Mill to the left. The way that the bundles of Rebar are shaped - or bent - is intentional according to the application. The only thing that puzzles me is the structure at the far right closest to where the photographer is standing? Source: Stelco Flashes. Jim Josway: LOT of weight in those gondolas. Structure to the right - reheating furnace? And just past that a flying shear? Just guessing. Stelco Rod and Bar Hamilton: Jim Josway thanks for your suggestion re: the structure to the right ... I thought it might be a reheat or patenting furnace as well. Jim ... Dave Warren: Why don’t we still make rebar here instead of buying US crap? Stelco Rod and Bar Hamilton: Dave Warren the company that bought Stelco's Bar Mill and #3 Bloom Mill, called Max Aicher, or MANA for short, still produces a proprietary type of heavy Rebar today, Dave. When U.S.Steel bought Stelco, they had no use for the entire Rod & Division so they closed it down D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 1963 - Stelco's NEW Reinforcing Dept. at the extreme North end of Parkdale Ave, in Hamilton, Ontario, Canada. A new innovation at the Reinforcing Dept. was the use of an overhead crane with FOUR magnets suspended from a 50-foot Bale. This allowed the crane driver to pick up bundles of steel without the use of chain slings. Source: Stelco Flashes. Wayne Kennington: I used to operate that crane. It took a while to learn how to stop the boom from swinging but once you got the hang of it, it was a great job. I loved being up high above the shop floor. It was my favorite job in the reinforcing department. John Cardwell: The biggest fear was during a storm and a blip with the hydro and down came the lift. D Eric Davis shared |

|

| Bubba Dubs posted Stelco Nanticoke Ontario. BD drone photo, 2023 |

|

| Stelco Rod and Bar Hamilton posted For the next week or so, I will be highlighting Stelco's venerable SPIKE MILL, which actually preceded the formation of the Steel Company of Canada. This Insurance map (from McMaster University) is dated 1903 and shows the "SPIKE FACTORY" in its original location just inside the main gate at the end of Harvey Lane (Wilcox Street). The Spike Factory had windows on both the north and south sides with a pronounced sloping roof. The floor was concrete while the sides were brick, as can be seen in many of the photos I'm going to publish. The reheat furnaces were located at the east end of the factory. I'm told that the floor was so low, compared to the outside grade, that in a heavy downpour, the factory would flood, and sometimes the employees would be sent home. This mill would continue to produce Spikes for the Railway Industry until production was moved to the Industrial East End of Hamilton in a building that was initially called the 'Reinforcing and Fabricating Department' but later renamed 'Bar Processing.' This mill MUST have been a money-maker: there's no way it would have lasted almost 100 years, otherwise. I've highlighted the Spike Factory in GREEN on this 1903 map. |

|

| Stelco Rod and Bar Hamilton posted Here is the Spike Mill in 1917. From the description in my previous post, you can see how unique this Mill was. It looked basically the same when I started at Stelco 1973, having to walk right past it every day that I worked. This photo is part of a very wide panorama which attempted to show the entire plant in one image. I will be posting parts of that panorama. D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted This 1917 photo is quite significant for several reasons. First, it shows the West end of the Old Spike Mill on the bottom right. More importantly, this MUST be one of the very first images that shows the Steel Company of Canada's # 2 Open Hearth. # 2 Open Hearth was built between 1916 - 1917 so there can't be very many photos taken before this one that show the exact location of the newest Open Hearth at that time. # 1 Open Hearth is in front of #2 Open Hearth. The trees on the bottom, middle, obscure the main entrance to the plant for both foot and vehicular traffic. Right above the height of the trees is the building that housed the punch clocks where all hourly employees had to punch in and punch out. Lastly, this photo is another segment of a very wide panoramic photo that I will post soon. Neil Lemieux: #1 open hearth - Field services change house, car repair derrick repair . D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted 939 Stelco Hamilton Open Hearth Scrap Yard D Eric Davis shared |

|

| Stelco Rod and Bar Hamilton posted Undated Stelco #2 Open Hearth. The train tracks rising up to the second floor look rather new ... I'm thinking this is the West side? (Thanks for the help, fellas ...) D Eric Davis shared |

|

| Glenn Gillis commented on the above post This ramp indicated by blue arrow in the photo |

|

| Stelco Rod and Bar Hamilton posted "Blue on Blue" > This is NOT 1971 as I previously posted. Thanks to the sharp eye of one of our diligent visitors, Mark Harvey. This photo was taken after USS bought the plant and painted it blue. The 3 chimneys were already demolished. This photo was shared to our page by James Gaulton. HISTORY: In December 1971, Stelco’s Basic Oxygen Furnace (BOF) plant at the Hamilton Works officially entered operation, marking a major technological milestone in Canadian steelmaking. The facility consisted of three 120-ton oxygen converters, each 30 feet high, and was capable of producing over 2.8 million tons of steel annually. The towering 20-storey steelmaking building covered eight acres, with an adjoining 3½-acre mould preparation building. Equipped with automated and computerized controls, the BOF represented a shift toward greater efficiency, precision, and reduced labor intensity. A key environmental investment—a $5 million fume collection and electrostatic precipitation system—was installed to control emissions and improve air quality. Using high-purity oxygen to refine molten iron into steel, the new process replaced older open-hearth methods and positioned Stelco at the forefront of modern steel production. D Eric Davis shared |

Stelco Rod and Bar Hamilton posted two photos with the comment:

Stelco's new Batch Anneal provides a perfect 'KODAK Moment' backdrop for visiting Politicians who want to show that Steel still matters to Hamiltonians ... (Thanks GT)

D Eric Davis shared

Joseph Germano: we have 2 anneals in farrell pa with the ebner furnaces went online in 2001-02

|

| 1 |

|

| 2 |

|

| Stelco Rod and Bar Hamilton posted This is the 7th of 20 photos from my John Pelrine Spike Mill Collection. This is a close-up of the Spike production process at the original Spike Mill just inside Stelco's Main Gate in Hamilton, Ontario. On the far left, a hot bar is exiting the reheat furnace and is about to enter the spike manufacturing machine. My question is: where is the operator of the machine? I thought this process required manual intervention and was NOT automated? Can someone please explain? |

.jpg) |

| Stelco Rod and Bar Hamilton posted This is the 6th of 20 photos from my John Pelrine Spike Mill Collection. Can anyone identify the man on the far right? On the far left we can see the end of one of the reheat furnaces. |

A 0:32 video overview from someplace high. Unfortunately, it is in profile format.

Steve Hinds: I'm guessing the top of #6 Battery waste heat stack.

7 1990s photos of "D" BF (Taken with a junk disposable camera so that he would not loose his good camera if caught.)

No comments:

Post a Comment