This prime lakefront property does not have condos. That is a testament as to how badly steel mills pollute the land. Instead of condos with a lake view, the brownland sits idle for decades until industrial activities can be found to redevelop it. [WIVB] $20m has been spent on cleanup. But it wasn't until Oct 12, 2020, that a court order forced the owners to pay $35m more to cleanup the remaining 489 contaminated acres. The coke ovens were used until 2001. And I have learned that they are generally the bad polluter in integrated steel mills. The peak employment was 25,000. [BuffaloNews-cleanup, paycount]

Republic used to have a steel mill in Buffalo, but it has also been abandoned. Republic in this case is a new company that still runs the 13" mill that is still on this site.

This plant received iron ore pellets from Bethlehem's Marmoraton Mine between 1952 and 1978.

I've looked at a lot of HAER records. This one has the most photos (180) and the least amount of information that I have yet to see. Every photo has the same worthless caption. And I could not find any overview photos or the usual "data" file.

|

[This is obviously some pollution control equipment. But is it for the BOF or for something else?] |

|

| HAER NY,15-LACK,1- [More pollution control. But what was inside the building?] |

|

| steel-photo via pinterest via Facebook Kevin Bruyne posted Bethlehem Steel in Buffalo . Big Steel Employed 10s of thousands of workers . |

|

| Authentic Buffalo History posted Bethlehem Steel 1963 |

|

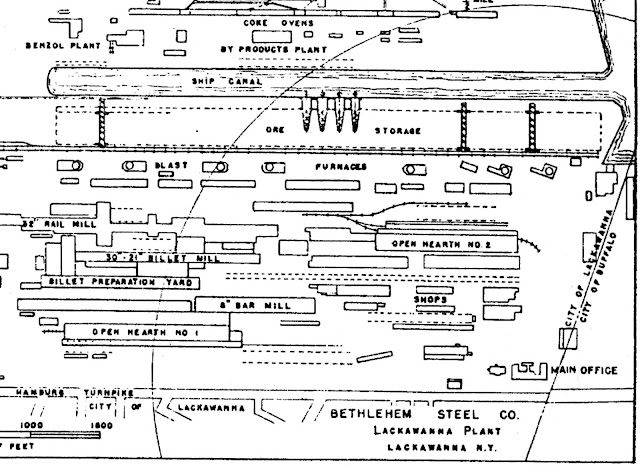

| Authentic Buffalo History posted The 1023 acre property of the Lackawanna Steel Company in 1914 |

Brian R. Wroblewski posted six photos with the comment: "Some niiiiiice stuff from the NYS archives....Bethlehem Steel, Lackawanna, Oct., 1949..."

Brian R. Wroblewski: This was Oct. 1949.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

David Warner posted three photos with the comment: "Bethlehem Steel Lackawanna from the 1950’s with an “after pic” for good measure."

Bubba Dubs: Thanks for posting my content!! I appreciate you trying to take credit for my work little bud

Boyle Mdumon posted another plagiarism of Bubba's work.

|

| 1 |

|

| 2 |

|

| 3 |

|

| Brian R. Wroblewski commented on Michael's comment Thats not slag along that wall, thats the Army Corp's CDF for dredge wastes from the Buffalo River inside that facility that the wall protects. |

|

| James Torgeson posted Lackawanna Steel two years earlier. Note the four Huletts unloading limestone from a laker. Steelmaking ended in 1983. |

|

| Bubba Dubs commented on James post Love how much land was filled in with slag and other materials since this was taken....... |

|

| Chairs Lion posted This is a photograph of the Coke ovens lower right the ordox center and the blast furnaces top left. This photograph was taken in the 70s. Jim Connolly: This is a great picture of the Lackawanna Bethlehem Steel plant the furnaces on the top portion of the picture , the ore docks next to the lake freighter in the ship canal , the Coke ovens ( gates of hell ) I the lower portion of the picture I worked in the coke ovens ( in a de sulfuring operation where the white smoke is coming out of smoke stake) I also worked the ore freighters before the plant in the 1960’s Very exciting places to work ….. hard working people making a living for their family. A proud part of Buffalo history [Some comments blame Bill Clinton and his NAFTA Bill even though that was in the 1990s and the mills were shut down in the 1980s.] Bobby Adams shared Isaac Pennock: SS Sparrows Point |

| |

| Chairs Lion posted Steel History: Did you know that in 1941, Bethlehem-Lackawanna Steel was the largest steelmaking operation in the world? Bethlehems shipyards built 1,121 ships, more than any other shipbuilder in World War II. At BBF, we try to keep Buffalo’s history of steel work, alive. John Groves: Bethlehem Steel Lackawanna was NEVER the world's largest steel plant. Ted Straub shared | . |

Chairs Lion posted two photos with the comment:

Bethlehem Steel Lackawanna, 1983.Pictured are blast furnaces H and J (top left between light colored smoke stack) and the steamer Sparrows Point unloading.The Bethlehem plant stopped producing raw steel soon after this photo was taken, but soldiered on for a time as a finishing mill, as well as a coke plant after the hot end (blast furnaces and basic oxygen furnaces) were shut down in 1983. The coke plant shut down in 2001 and the last bastion of the main steel facility, the 13inch bar mill, was just closed last fall when Republic Steel technology shuttered the plant.The Sparrows point was later converted to a barge, and recently visited Buffalo as the Menominee. Drone shot from January.

James Wojtanik: I don’t see many detailed aerial views of the Lackawanna plant like this. Thank you for sharing!

|

| 1 |

|

| 2 |

|

| James Cavanaugh Photography posted From my Archive. A 2003 view of the former massive Bethlehem Steel site in Lackawanna, NY. The site is just south of the Buffalo, NY border and on the shore of Lake Erie. Jim Cavanaugh shared |

.jpg) |

| James Cavanaugh Photography posted From my Archive. A 2003 view of what was once the sprawling Bethlehem Steel Plant in Lackawanna, NY. Jim Cavanaugh shared with the same comment Brian R. Wroblewski: Man, Soooo much has changed since then. All new buildings everywhere. Reused old buildings, track re-alignment, new equipment & storage on the docks, new businesses. Windmills, & lots of clean up work. James Cavanaugh Photography shared another posting |

|

| James Cavanaugh Photography posted From my Archive. A 1987 view of a portion of the former sprawling Bethlehem Steel plant in Lackawanna, NY. Jim Cavanaugh shared with the same comment. Brian R. Wroblewski: Groovy. You can see the transfer table for the Huletts in the upper right under the ore bridge on the flooded ore dock. |

|

| James Cavanaugh Photography posted From my Archive. A 1987 view of the M/V Arthur M Anderson in the Ship Canal at the former Bethlehem Steel Plant in Lackawanna, NY. Jim Cavanaugh shared From my Archive. A 1987 view of the M/V Arthur M Anderson in the Ship Canal at the former Bethlehem Steel Plant in Lackawanna, NY. [Some comments discuss if they are loading coke, coal or a blend. It would be for export.] |

|

| Bubba Dubs commented on Brian's comment [Bubba added this photo to a discussion about the four Huletts.] |

|

| Jon Wolfe posted Bethlehem Steel, Lackawanna NY Jeff Pilger: I work there now they still use the coal tipper. Ronald Ball: when was this taken ? I worked for the South Buffalo RR and remember tracks into this building. Also the SB roundhouse in upper right corner and a train on the high grade next to round house. Also the long bridge that collapsed... Leland C. Johnson: The Galvanized Mill is not there yet… Mike Clifford: Leland C. Johnson for sure this is prolly 1950’s. The 10” bar is the one pictured at the bottom. The 13” didn’t come in line until the 70’s. Mike Clifford: Bar mill in the foreground with the 79” strip mill next to the cold mill. In the background you can see the structural mills, rail mill, blast furnaces, coke ovens and what looks to be No. 3 Open Heart. Ted Straub shared |

|

| Brian R. Wroblewski commented on Jon's post and Ted's share 10" bar mill in the front & the hot & cold strip mills further back. Mostly all still there. [https://www.google.com/maps/@42.8051436,-78.8466168,1815m/data=!3m1!1e3] |

|

| Bradley A. Lacko posted Bethlehem Steel - Lackawanna, NY **Not my picture** Jonathan Degenaars: Work there the last 5 years it was operational. Video of one of our last shifts at the tandem mill. https://youtu.be/pRq7EazusZ0 Ted Straub shared |

|

| Martel Gause posted View of Bethlehem Steel, Lackawanna. |

|

| Martel Gause posted Lackawanna, NY - Hulett Ore Unloaders |

Kevin Peterson posted 15 unique photos with the comment:

Remember it 3 July 2015Lackawanna Plant, Photos from Robert Miller Millright Class A

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| 11 |

|

| 12 |

|

| 13 |

|

| 14 |

|

| 15 |

|

| 16 |

Paul Wicka posted four photos with the comment: "I took these photographs sometime in the '70s. The one on the left is taken from the crusher building looking down the trestle. J furnace is in the forefront. The ore dock is on the left. The top right photo is taken from The trestle looking South back towards the crusher building and J furnace. The photo in the middle is me . I was a welder in a millright gang in the blast furnaces . the last one is a picture of a cinder pot underneath B furnace. also all these photographs are of Bethlehem Steel Lackawanna New York plant."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| James Torgeson posted The iron ore cargo of Bethlehem Steel's Str. Steelton is almost gone, and front-end loaders are being lowered in the holds to help round up the final remnants so the Hulett Unloaders at the Bethlehem Steel Lackawanna Plant can scoop them up. The plant's four 17-ton Huletts were in operation until steelmaking ended there in 1983. Don Stransky: In the 70’s we had one cleat-track dozer that dropped from hatch level when a cable sling broke . They tried to use it for spare parts but everything they pulled off was broke . John Blaine: Don Stransky it didn’t punch a hole in the hull? Don Stransky: John Blaine No it hit bottom after spinning 180° and pointing in the opposite direction . The bottom looks like I-beams laid side by side running crosswise . They used a D-9 dozer to drag it up the hill . |

Association for Great Lakes Maritime History posted three photos with the comment: "Three images from glass negatives, circa 1895-1900, showing iron ore being unloaded by Thornberger hoists at the ore dock of the Lackawanna Steel Co. near Buffalo, New York. At the same time, the vessel is being bunkered with coal by a steam shovel mounted on a barge (Image Source: Library of Congress - Detroit Publishing Co. Collection). [The description goes on to provide details about the freighters.] "

Wes Oleszewski: A lot more detail concerning these images can be found in this video:

|

| 1 |

|

| 2 |

|

| 3 |

|

| Steel Plant Museum of Western New York posted Artifact of the Week! Look at this awesome aerial view of the former Lackawanna Plant! This photo was taken on August 31, 1999! Tom Tomaka: Funny, how compressed the view is. Didn't the plant occupy about 3 miles of shoreline? Steel Plant Museum of Western New York: Tom Tomaka Yes, pretty close to that! Steel Plant Museum of Western New York shared |

|

| Bob Bratina posted |

|

| James Torgeson posted Two aerial photos of the Bethlehem Steel Lackawanna Plant taken on May 9, 1980. Blast furnaces at the top (east), coke plant at the bottom (west). [The comments discuss how many coke batteries this plant had.] |

Mike Delaney posted four images:

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Seventh of twelve images from a 1970 booklet posted by James Torgeson |

|

| Smithsonian Institute, p46, 1919 |

Bubba Dubs posted five photos with the comment:

Here is a little more detail into what I see in this photo for anyone who wants to know about the furnace arrangement at Lackawanna. I did this for a local group, so I’m sorry if I go into too much info you guys already know.Anyhow, I found this absolutely spectacular photo of Bethlehem Steel Lackawanna from 1943. In this pic you can see the lake freighter Merton E Farr (Thanks Fred!!) getting unloaded by the Hulett unloaders. Up until self unloading vessels were the norm, most docks had to have some type of unloading mechanism. Bethlehem had the Huletts, up to (5) of them at one point. I this picture, it looks like 3 or 4 of them are doing the unloading. Places like Hanna (3rd pic) had bridge cranes with ends that folded down to extend over the vessels. Other docks like the Pennsy dock across from Hanna had the brown hoists. The Huletts were the top of the line and could converge on a vessel (2nd pic) and have it unloaded in about 4-5 hours.This pic is very interesting from a perspective point of view and had me thinking. In the end, it was taken at the very end of the slip, with H furnace on the right, F and G hidden behind the bridge crane bases in the middle. C is way on the left behind the Huletts. Out of view (4th pic) are Lackawanna Iron Vintage B and A. To the right would be where J furnace (not I because that is confused with a 1) was out of frame. Lackawanna originally had 9 furnaces, but D and E were abandoned in 1928.1943 taken from the Buffalo Memories II book, Hanna pic from a personal photograph, color photos of Bethlehem from the Bethlehem Steel Lackawanna Plant brochure from 1950’s.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| Jay Borzillieri posted Bethlehem Steel's 10" Bar Mill Lackawanna, NY ... shutdown before they built the 13 ... Ron Peoples: 1948 ? Wow, look how clean and well maintained that place is. I can assure you that it has not looked the same in many years. Jay Borzillieri: It's actually our loading dock now. The speed pulpit is still there. I am a Roller on the 13" now. We are operating as Republic Steel. |

Antonia Ignazio Medina posted two photos with the comment: "The Korting blowing engine for blast furnace, and Transfer Bridge's at Bethlehem Steel Corporation,Lackawanna,NY plant."

Bubba Dubs: Those Kortings were replaced by Bethlehem built engines after they acquired Lackawanna Steel in 1922. They had to be placed sideways because they were longer than the Kortings.

|

| 1 Antonia Ignazio Medina posted Blowing Engines Lackawanna Steel Company. 1907 John Salgado Danek: Compressors ???? Pete Steffey: John Salgado Danek after a fashion . Huge volumes of air have to be pushed through ducting , heated checkers in stoves , more ducting , through tueres ( the special injection nozzles) and into the blast furnace . |

|

| 2 |

|

| Antoniao Ignazio Medina posted Steel workers pour steel ingots in the open hearth department in 1941 Bethlehem Steel. Lackawanna,NY Kenneth Treharn: Nothing like a "full running stopper Jeff Berkoben: Kenneth Treharn That's when you hope you have a good craneman, and most were very good. [I wonder where the crane operator moved the ladle so that it would empty somewhere safe. A crane operator also mentioned "burn throughs" as well as "runners." Continuous casting made pouring ingots obsolete.] |

|

| Antoniao Ignazio Medina posted Loading lake boat with rails, Lackawanna,NY Plant. 1905 |

|

| Antoniao Ignazio Medina posted Three stand roughing train, Lackawanna Plant, Bethlehem Steel Company. Lackawanna,NY. 1955 |

|

| Antoniao Ignazio Medina posted Blast furnaces, Lackawanna Steel Company. Lackawanna,NY Plant. 1905 Bubba Dubs: Those furnaces might’ve been taken down in Scranton and rebuilt in Lackawanna. They did take a lot of equipment from Scranton. |

|

| Antoniao Ignazio Medina posted Blast furnace looking at cast house, Bethlehem Steel Company. Lackawanna,NY 1929 |

|

| Antoniao Ignazio Medina posted Blast furnaces under construction. Bethlehem Steel Company. Lackawanna, NY 1930 |

|

| Antoniao Ignazio Medina posted Blast furnaces showing cast house and erection of steel at top works, Bethlehem Steel Company. Lackawanna,NY 1930 Mark Goodrich: Those style of derricks are called Chicago booms. |

|

| BuffalowHistory.com posted Bethlehem Steel Corporation - Lackawanna Plant - Route 5 on Lake Erie- Buffalo, NY https://www.buffalohistory.com/bethlehem-steel-corporation-15853.html Ted Straub shared |

|

| BuffalowHistory.com posted Bethlehem Steel Corporation - Lackawanna Plant, Route 5 on Lake Erie Shop Today! ➡️ https://www.buffalohistory.com/bethlehem-steel... James Torgeson shared Don Grosso: sintering plant, I think |

John Murnan II posted two photos with the comment:

Bethlehem Steel, Lackawanna, NY

Brian Wroblewski photo

https://bethlehempamatrimonial.blogspot.com/.../bethlehem... [I could not get past some "I'm not a robot" dance.]

Steel Plant Museum of Western New York: There's no era specified for either photo, although the 2nd one is after the hot-end was shut down in 1983. |

| 1 |

|

| Don Cassata posted A 1952 Bethlehem Review showing Lackawanna's new "J" blast furnace. |

A different scan because the colors are different.

|

| Raymond boothe posted View of a Lackawanna Plant blast furnace on the cover of the Bethlehem Steel Annual Report of 1952 (Dr. Raymond Boothe collection). |

Steve Vanden Bosch posted three photos. The initial part of his comment: "William S Mack unloading at the Hullet in 1908 at Buffalo New York. She was built in 1901 by American Shipbuilding Co. Lorain. She ended her days as the 1st Algorail when she was scrapped in 1963 in Toronto. This photo is from the Library of Congress."

|

| 1 |

|

| 2 |

|

| 3 |

|

| Brandon Parsons posted Conveyor tunnel; Bethlehem Steel facility in Buffalo, New York. [Some comments debate which conveyor belt this was.] |

|

| BuffaloHistory.com posted Bethlehem Steel Corporation - Lackawanna Plant - Route 5 on Lake Erie - Buffalo, NY James Torgeson shared A view of the Bethlehem Steel Lackawanna Plant after steelmaking ended. This looks from the empty and flooded ore yard, across the large slip towards the active coke ovens. The remaining ore and limestone has been shipped to other Bethlehem plants or sold on the open market. Blast furnace row is behind the photographer and the plant’s four Huletts are out of sight to the right. Chairs Lion posted Bethlehem Steel Corporation - Lackawanna Plant - Route 5 on Lake Erie - Buffalo, NY |

Three of 45 images from BuffaloNews.

|

| 1 "An undated aerial view shows the Bethlehem Steel plant in Lackawanna pumping smoke into the sky." By Buffalo News file photo |

|

| 6 "An undated photo of Bethlehem Steel found with other photos from the 1920s-60s." By Buffalo News file photo |

|

| 10 "October 1962: Bethlehem Steel installed this new 52-inch contour lathe in its Lackawanna plant as part of program to improve its production facilities in the early 1960s. It is shown here machinging a roll from from a 110-inch, 28,000-pound casting which Bethlehem used in its own steel-rolling operations. The lathe had an over-all length of 40 feet and, along with a template, can contour intricate shapes." By Buffalo News file photo |

In 1983, everything was closed except "the coke ovens and byproducts division, Cold Strip Mill, 13" and 12" bar mills, and the galvanizing department still remain." [buffaloah, this site has more of the now defunct Bethlehem timeline.]

From the captions of other photos in that 45-image gallery, we learn:

From the captions of other photos in that 45-image gallery, we learn:

- 2: "1903: The Bessemer converter, transported from Scranton, PA., to the new Lackawanna plant in 1902, produces the first steel in Oct 1903. Bethlehem Steel Corp. acquired the plant in 1922 from the Lackawanna Steel Company." [So was it manufactured in Scranton or did a Scranton steel plant scrap the converter because they upgraded to an open hearth furnace? Neither, the company moved: "Originally founded in Scranton, Pennsylvania, the Lackawanna Steel Company moved its operations to Lackawanna, New York (a small city just outside of Buffalo) in 1902. After its transition from Scranton, the Lackawanna Steel Company grew rapidly, thereby removing workers and machines from its Scranton operations. Lackawanna’s new steel plant quickly grew and prospered as the leading manufacturer of rails and sheet piling." [lipsitzponterior]]

- 3: In 1936 they installed Bethlehem's first hot strip mill in Lackawanna. [Was this Bethlehem's first HSM, or just the first in this town? It covered 22 acres and cost $20m.]

- 9: An Apr 1962 photo shows a control room.

- 11: A new $20m 1000' galvanizing line was started in Nov 1962.

- 12: A Nov 1964 photo of the control room for the basic-oxygen furnaces.

- 14: A $50m bar mill was being constructed in Oct 1973.

- 17: A $10m upgrade of the galvanizing line was done in 1981.

- 18: Another photo of the galvanizing line.

- Most of the photos from 21 on provide dates as to when various facilities touched their last piece of steel.

- 28: An exception to being closed: a Sep 1983 photo of the 13" bar mill control center.

The .jpg version is unreadable even if you download it and use a photo app. But it provides the context for the next two images that were cropped out of a .tiff version. They are readable if they are downloaded.

|

| jpg via HAER NY,15-LACK,1- |

|

| tiff via HAER NY,15-LACK,1-, cropped |

|

| tiff via HAER NY,15-LACK,1-, cropped |

Above was the second of 8 images. There are also layout maps for 1905, 1950 and the following 1984, which would have been the status when it was shutdown in Oct 1983.

|

| jpg via HAER NY,15-LACK,1- [I verified with the .tiff file that the new buildings in the lower left are not numbered.] |

|

| Bubba Dubs posted |

|

| Bubba Dubs posted Bethlehem Steel’s Lackawanna plant was once a large integrated mill, with 7 blast furnaces, 3 open hearth shops and later 3 BOF vessels. Little remains as it was, the coke ovens are mostly still there and the boiler house and old blowing engine buildings still leave some clues to what was once here. Kevin Peterson posted Aerial View of #Bethlehem #Steel Plant at Lake Erie in the south part of Buffalo, New York, USA Metro Area in the 1970s. Horrible what so many were subjected to with lung cancer and other respiratory system cancers in the world before mass public place smoking bans and pollution control laws were put in place in the United States and Canada. They weren't all the good old days. A lot is better today though not a perfect world today but much better and cleaner than back then. Hickory D. Doc: Lackawanna plant employed 25,000 in the 70,-80's. Poor management and politics closed the plant and company. |

In 1922, the second largest steel company in the United States, Bethlehem Steel, purchased the Lackawanna Steel Company for a mere $60 million. At this time, the Lackawanna plant was just over twenty years old and was beginning to show its age. Bethlehem Steel spent over $40 million in repairs and updates to the plant so that it could remain a large competitor in the steelmaking industry.By 1941 and at the start of World War II, Bethlehem focused its operations on steel plate production for ships and tanks, as well as structural steel for the military. During World War II, Bethlehem’s Lackawanna plant became the world’s largest steelmaking operation employing over 20,000 workers on its 1,300 acre site. The Lackawanna plant’s prosperity lasted well into the early 1970s.In 1977, the Lackawanna Plant began to make cuts in its production and workforce due to decreased demand for steel and the sudden onset of steel imports from foreign markets. Despite company complaints with regard to declining profits, Bethlehem’s Lackawanna Plant was profitable every year from 1970-1981, with the exception of 1977. Bethlehem Steel closed most of its Lackawanna plant by 1983 due to rising operational costs and the decreased demand for steel. Located on the shores of Lake Erie, the Bethlehem Steel Lackawanna Plant was once considered the 4th largest steel mill in the world.

|

| Steel Plant Museum of Western New York posted A photo of the Machine shop at Bethlehem Steel Lackawanna NY plant, taken in 1967. [Some comments discuss the refurbishment of the bell top in the right center just two years before the bell-less top was invented.] |

|

| Jon Dube posted in Bethlehem steel historical Memories November 1962: A coil of cold-rolled strip steel is swung to the start of a new 1000-foot galvanizing line, a $20 million facility put into regular production at the Bethlehem Steel Co.'s Lackawanna plant. Brian R. Wroblewski shared Thats, ironically, all a scrap plant now owned by Metallico. They have their shredder where the old galv line once was in there. |

|

| Leslie Carr commented on Brian's share I always loved this pic..I try to picture it when I go past there.. which is difficult because it's rush hour and the Hamburg 500 is on😅 Chairs Lion posted I always loved this picture.. what a place it was. Once upon a time in Lackawanna, NY🩶 |

|

| 3D Satellite "Steel Winds, an eight-windmill wind farm owned by BQ Energy, opened on the old plant’s slag heaps in September 2006. Another 14 turbines were added in 2012." [ThePartnership] |

These posts were my motivation to research this plant. I thought Republic Steel had been absorbed by LTV. Did someone recycle the corporate name? Evidently.

Republic Steel 13" Bar Mill posted six photos of Republic Steel.

James Torgeson posted

Bubba Dubs posted eleven photos with the comment: "In my continuing Bethlehem Steel kick, I finally got over to the east side of route 5 to check out that side of the mill. The area across from the “hot end” of Lackawanna consisted of a cold strip mill and associated processes, hot strip mill, 13 inch bar mill (now Republic) and the galvanizing line. I’ve posted a Google maps overhead laying out the mills."

[The eleventh item posted was a video that started with a pan of the whole complex.]

|

| 1 Blue: Cold strip Red: Hot strip Yellow: 13 inch bar mill (Republic) Orange: Galvanizing line |

|

| 2 Over cold strip mill. Hot strip in distance followed by 13 inch bar mill, now Republic |

|

| 3 13 inch bar mill |

|

| 4 Power house |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

Sam Bennett added these photos to Bubba's fifth photo.

|

| 1 400ft cooling bed |

|

| 2 Looking east from A line shear shanty |

|

| 3 Looking west from A line shear shanty towards the bundling bed (krasny) |

|

| 4 B line shear upper blade clamp broke off. |

|

| 5 Catwalk view of the channel and kick off onto the cooling bed |

|

| 6 Old 10inch mill bay used for storage. |

|

| 7 Looking north from a line shear into the warehouse. |

|

| Matt Celeste posted Republic Steel - Lackawanna, NY (12/30/22) Tod Fillman: Don’t this still run? Pat McCon: Tod Fillman - The last I knew, yes. It was actually the nicest of the ‘new’ Republic Steel’s mills when I used to visit there. Maintenance was good, the place was clean and well-lit, and they were far enough away from Canton that they hadn’t unlearned the Bethlehem safety culture. It got awfully hard to make any money on bars. There were too many bar mills, and the cost to get into that business was low enough that even more mills were built. And it’s easy enough to make that the old, worn-out mills could keep their customers. Even SBQ is too commoditized. J.D. Haltigan: Pat McCon Silly question, but what is a 'bar mill'? I get bars, but more specifically...? Barry Schneider: J.D. Haltigan I believe that mill made round bars from 1" up to ~7", Round Cornered Squares from like 3" to ~8", and maybe smaller hex shaped bars. SBQ is special Bar Quality which means clean steels and lots of performance. Mostly forged stuff or cold drawn, think axles, hydraulic cylinders, crankshafts, cam shafts, etc... Pat McCon: J.D. Haltigan - Here ya go. 😁 https://www.britannica.com/.../steel/Billets-bars-and-rods The definitions are a little ‘squishy’. E.g. Republic made coiled rod in Cleveland but called it the Bar Mill. At J&L in Aliquippa we called it the Rod Mill. And to make it even weirder, in a hot strip mill as the metal moves thru the stands the part that’s after the last roughing stand and going into the first finishing stand is called the ‘bar’. I guess because it’s no longer a slab and not yet a strip. 🤔 Pat McCon: J.D. Haltigan - Railroad axles are forged from cast ingots. I think there are some axle-making processes that look like rolling, but they’re still forging processes. I think. A rolling mill makes the same cross-section from beginning to end of the piece. Rail axles aren’t of uniform diameter - where the wheel is pressed on is smaller than the rest of the axle. I guess you could roll a short billet and machine it, but I reckon there’d be a lot of waste. And the metallurgy may not be right. https://www.amstedrail.com/.../freight-car-components/axles/ Jeffrey Pantano: Was a fun place to work in the 13 inch bar mill. Wonderful people there doing their best to keep it running still. |

|

| 3D Satellite |

|

| One of eight photos posted by Bubba Dubs A few pics of the former Bethlehem Steel Lackawanna plant with an arriving ocean going freighter with raw sugar from Brazil. |

This is why they are bringing in sugar by the boatload, literally.

|

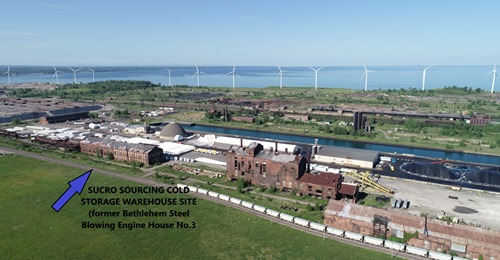

| safe_image for Portion of former Bethlehem Steel site to become Sucro Sourcing warehouse Gas blowing engine house #3 is being repurposed here at Bethlehem Lackawanna |

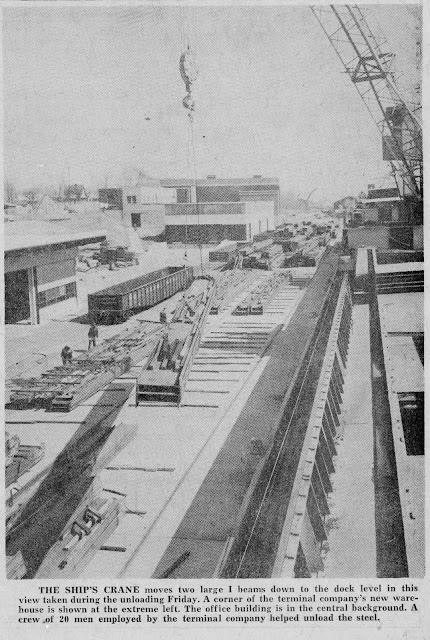

Jim Luke posted five photos with the comment: "Bethlehem Steel's craneship CAMBRIA - opens the season at Port Huron Terminal - the former general cargo dock - on April 21, 1962 with a load of steel coils and beams. This event was covered by the Times Herald for a Saturday photo story. Luke Collection"

Steel Plant Museum of Western New York shared

The primary reason Lackawanna Steel relocated to Western New York from Scranton, was the relatively inexpensive water delivery of raw materials of both iron ore and fluxstone, as in Scranton these had to be delivered by rail. Another benefit of the new location was that finished steel products could also be shipped by water to cities on the Great Lakes, and to the world after 1959 when the St. Lawrence Seaway opened. In these April 1962 views, we see a Bethlehem Steel crane ship in Port Huron, MI, unloading beams that were rolled at the Lackawanna Plant.

Karolina Tissel: My father’s family moved to Lackawanna from Scranton. I presume the reason was “follow the jobs”. They were Finnegans originally from County Sligo, Ireland.

|

| 1 Malcolm B. Thompson: Remember seeing the crane Lakers and wonder what they carried. |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 Fred Miller II: Many of these were for the I-94 overpasses. |

|

| James Torgeson shared a photo from Steel Plant Museum of Western New York One of the three BOFs at the Bethlehem Steel Lackawanna Plant, which ended steelmaking in 1983. In 1964, Lackawanna received the first BOFs within Bethlehem Steel. This image is featured on the SPM’s rack cards. |

|

| Antonio Ignazio Medina posted Bethlehem Steel Company Lackawanna,NY. Slag ladles Gregory Sanchez Jr: Those are Slag pots, when i started at YoungstownsheetandTube i was a ladle dumper, if water was in pit the slag hit that crap and a big explosions Jerry Barbic: That sure looks like the BOF!!! [There are quite a few comments about how other plants handled their slag.] |

|

| One of four photos posted by Bubba Dubs Bethlehem Steel Lackawanna had some interesting power pylons. They looked to be made of structural steel. I’ve always been impressed by them!! James Torgeson: Bethlehem did make them at one time. |

Bubba Dubs posted three photos with the comment: "Republic bar mill, Lackawanna NY."

|

| 1 |

|

| 2 |

|

| 3 |

|

| Rick Cups posted The following photo was taken in the spring of 1976 by one of Bethlehem Steel's corporate photographers. It was start-up day and this is the first billet into a new 13 inch Bar Mill in Lackawanna, NY... Larry Furlong: I was never able to tie a cobble in a knot like that. Appreciate the style. Jay Borzillieri: Mike Bronko I am a Roller at this mill currently. This is such a cool pic! Currently Republic Steel owned. In 2010 they modernized, eliminating 19-22 and installed a Kocks Mill. I didn't know you cobbled the first none at 7. All stories I heard were that it made it all the way to 22. Then cobbled. Mike Bronko: Jay Borzillieri I saw cobbles fly in the air the length of the cooling bed. This happened when the shear cutting them on the fly failed. These bars are moving at a very high rate of speed Jim Myers shared Irving Fartwhistle: And you have literally nowhere to go because there's no way to know where it's going to go. You just hope it misses you. I cut up my share of those things. We had a crane that had a hole in the floor from where the cobble went through and it exited through the glass. The glass got fixed but the hole in the floor and the burn marks on the cab stayed as a reminder. You really had to develop a 7th sense to work in a place like this. You needed to be in tune with all of your 5 senses, trust your 6th sense that something wasn't right, and the 7th sense to act as quickly and clearly as possible. You had to absolutely trust your senses to know when something didn't look right, smell right, sound right, feel right, and in a weird way, even taste right. Everything had a look, a sound, a vibration, a cadence or timing, a smell.....if it wasn't right, you needed to pay attention and check it or get someone who could. The life you save may be your own. |

|

| Cory Wantuck commented on Rick's post Still does the same thing. |

|

| Daniel Lamm commented on Rick's post They get hot lol |

|

| Charlie Gimbra commented on Rick's post |

|

| safe_image for Republic Steel to idle steelmaking in Canton Seems the republic steel plants in Canton ohio and Lackawanna New York are closing. [A comment pointed out that they are "indefinitely idling" instead of closing to reduce their financial obligation to the workers.] |

Chairs Lion posted six photos with the comment: "The former Bethlehem Steel Lackawanna plant’s Boiler house #3 has been repurposed into a sugar refinery. The #1 powerhouse, as well as #3 blowing engine house have been converted into warehouses and a bulk storage dome was built on the foundation of the former #3 steam plant. I never thought I’d see the day these old mill buildings would be repurposed into something that would see them endure!!"

Brian R. Wroblewski shared

Photos by: Bubba Dubs!

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| Brian R. Wroblewski commented on Chairs' post Unloading the raw sugar cane from Brazil in the Lackawanna Canal. |

Before Huletts:

|

| 7:10 video @ 0:41 Time machine unloading an oreboat and looking at a steam train in Buffalo New York in the year 1900 |

11 interior photos The eighth is the control panel in a pulpit. The tenth is a big stack of rolls.

7 drone photos of the hit strip mill

The pollution control equipment was used for the sinter plant.

ReplyDeleteThe sinter plant baked ore fines with other fines (coke, limestone) to make a mass that could be changed into the blast furnace. It was a way of getting rid of a lot of waste that otherwise wouldn’t have been able to use

ReplyDeleteGreat work on this by the way! Glad you could use the photos and put it all in one place.

ReplyDeleteThanks. Combining the photos helps me visualize what it used to look like. I continue to discover how many steel plants used to be in the US.

Delete