(Satellite, both sides of the river along this bend. See the topo map below. I've seen the claim that it covered seven miles of river front property.)

Now for some history. Given the bend in the river, we are looking upstream on the Monongahela River with Jones' rolling mills on the right (J&L Southside Works) and Laughlin's blast furnace on the left (J&L Hazelwood Works).

Speaking of "downstream on the Monongahela River," this view shows that part because we are looking upstream. There is another open-hearth furnace downstream from the hot metal bridge.

|

| Timothy Robbibaro posted While browsing the Jackson Township Historical Preservation page, I came across an old aerial photo of J&L dated from the 1960s. Inspired by it, I went out today (04/25/25) and captured a matching shot with my drone. I adjusted the edit settings to mimic the tone and style of the original, then placed them side by side for comparison. I think I came pretty close to replicating it. Back then, the original image was likely taken from a helicopter or airplane—mine was taken from about 400 feet up above the bike trail parking lot. |

The above photo is actually a small fraction of the J&L property in Pittsburgh (left side, Southside Works) and Hazelton (right side, Hazelton Works).

|

| 1951/51 Pittsburgh East |

|

| Sean Stewart posted Here is a print of the entire J&L Pittsburgh Works in 1957. [An uploaded .pdf of the diagram Unfortunately, it is not much better than the above image.] |

|

| Photo of a plaque by Mike Wintermantel via hmdb, cropped "The partnership between Jones & Laughlin combined the skills of an older financial genius with those of a brilliant young entrepreneur. Before the Civil War, Jones established a rolling mill on the South Side, and Laughlin subsequently built an iron furnace on this [location of marker] side of the river. The two firms formed the Jones & Laughlin Company. "J&L began as a family business and the principal partners trained their sons and brothers to take over executive positions. Jones based the management on "Vertical Combination"-the concept of owning raw materials, fuel, transportation, and other requirements needed to create a finished product. J&L owned iron ore mines near Lake Michigan, coal mines in Washington and Greene Counties, a Blair County limestone company, and drilled natural gas wells to supply the mill. The company established docks on Lake Erie and owned hundreds of barges. "On January 1, 1900, J&L made a momentous decision to shift exclusively to the fabrication of products made from steel. Although the Eliza blast furnaces continued to smelt iron used to make the steel, J&L no longer made iron products. "At its peak in the 20th century, J&L employed 30,000 workers and occupied over seven miles of riverfront. For more than a century, J&L's smoke stacks, furnaces, rolling mills, coke ovens and factory buildings lined both sides of the river." |

|

| Bob Ciminel posted Jones & Laughlin mill, 1875 Pete Steffey: There was one building left when I was there (70s-80s) that looked like it was from the mid 1800s. They called it “the old machine shop” . It was brick, with windows that had small panes of wavy bubble filled glass. Just east of the bridge( upriver) on the north bank of the Mon. |

Both of the above images are a reminder that smoke was considered a sign of prosperity in the 19th Century. Artists would had plenty of black smoke pouring out of very stack.

As the technology for processing iron advanced, coke production was added to the Hazelwood Works and steel production was added to the Southside Works. Mills were added to both sides of the river. To make things more complicated, National Tube Co. Continental Works in Hazelwood were absorbed by J&L. The downstream end of the CSX/B&O Glenwood Railyard is in the lower-left corner.

|

| engineering_history, Source: Hazelwood Green Ralph Cappella posted J&L Southside and Hazelwood works from a long time ago..... At their peak, they employed 12,000 workers.... Imagine that. Twelve Thousand people getting a paycheck to support a family. What many people don't realize is how many "other" lives the steel mills affected. Entire towns were built around the mills. These "Steel Towns" were built by thousands of carpenters, bricklayers, plumbers, electricians, etc. The bars, restaurants, grocery stores, clothing stores, etc, employed thousands more. Add to that all the vendors that sold to, and serviced those mills... |

Blue is one of the open hearth furnaces, Yellow is the blast furnaces, red and orange are the coke batteries, Green is the raw material stock piles and the bridge in the background is the Hot Metal Bridge. There is more of J&L out-of-frame on the top further downstream on the Monongahela River. I think red was the coke batteries back in the National Tube days, and orange was the last J&L facility along the river to be shutdown in 1998.

|

| Plus Paint |

Speaking of "downstream on the Monongahela River," this view shows that part because we are looking upstream. There is another open-hearth furnace downstream from the hot metal bridge.

|

| info-ren, 1959 |

And this is a closeup of the above around the hot-metal bridge.

|

| Ryan Van Harrison posted J&L, 1923 John J. Chapman posted J&L, 1923 James Ujevich: looks to be second avenue Hazelwood. And the hot metal bridge went to southside. Bob Whitten: You are right- Southside Works. |

|

| Rollie Puterbaugh posted Image taken over the Glenwood Bridge {lower right} in 1971. It shows Hazelwood, the coke and blast furnaces belonging to J&L Steel along Second Avenue. You can also see the Hot Metal Bridge that took the pig iron from Second Avenue across the Mon' River to the Southside Works. Copyright: Rollie Puterbaugh If anybody would be interested in seeing an expanded view of Hazelwood, let me know! Robert Friday shared Real Bubba: Glenwood Yard, B&O’s largest Pittsburgh operation with ability to handle 2,000 freight cars. Car repair shop and round house are center of picture. AVRR is there now although on a much smaller scale. Timothy Yarnall Sr.: The long building between the RR tracks, is that the B&O Glennwood shop? [According to Bubba, yes.] Dean Amrhein: Real Bubba the roundhouse is now a CMU facility. They've tried to preserve some of the original structure, but it's almost unrecognizable. There's no railroad activity of any kind going on there. Back in the 1990's a guy named Ernest Stern owned a steam locomotive and it was stored in the roundhouse. He was trying to restore it, and he had Downing Machine make thousands of dollars worth of replacement parts for it, but he never finished the project. Stern was the owner of the Cinemette Theatre chain. |

A closer view of the blast furnaces, bridge and evidently the remnants of the downstream open-hearth building. I say remnants because this view has fewer smokestack than the "info-ren" view has. A remnant would be consistent with the 1982 date. Open hearth furnaces were made obsolete by BOFs (Basic Oxygen Furnaces).

|

| Bob Zilionis posted J&L Steel - Pittsburgh Works - October 16, 1982. Bruce Vincent: I think that whole site was demolished in the mid/late 80's. Bob Zilionis: Bruce Vincent my Dad took this pic right before tearing down the blast furnaces. Thomas McDowell: Relined and lots of other work done to blast furnace in summer of 79 it’s was never fired back up. 1st job out of high school 8 weeks of work with boilermakers.sorry 75 |

This view is a little further downstream on the other side of the hot-metal bridge.

|

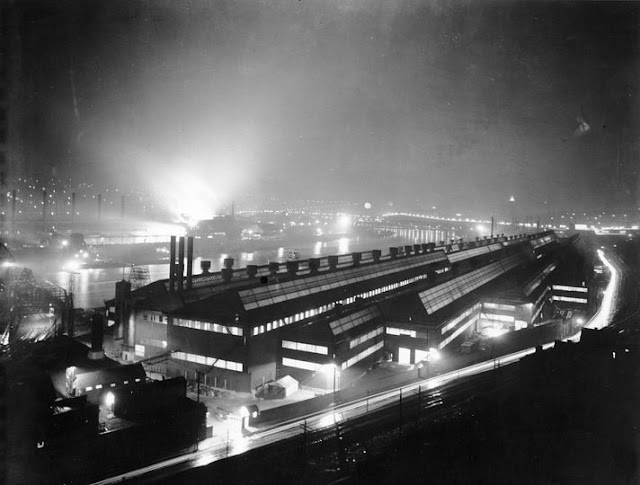

| Heinz History Center posted In July 1859, Laughlin & Company, later to become Jones & Laughlin Steel Corporation, acquired land on the north side of the Monongahela River opposite Brownstown (currently the South Side neighborhood of Pittsburgh). In addition to two blast furnaces, called Eliza furnaces, beehive coke ovens were built on this site. It was common practice at the time to name blast furnaces after wives, daughters, and mothers. The name “Eliza” was chosen because it was a common name in both the Jones and Laughlin families. The Eiza furnaces, the second blast furnaces built in the Pittsburgh metropolitan area, began operation in 1860. Additional furnaces were added over the years so that ingot capacity at the Soho Works, also called the Eliza Works, reached 1,740,000 tons per year in 1920, and two million tons in 1930. The plant, which employed over 5,000 people at one time, closed in 1977 and the enormous blast furnaces at the site were razed in the mid-1980s. 📸 Jones & Laughlin Steel Corporation Soho Works at Night, undated. Jones & Laughlin Steel Corporation Collection Photographs, Detre Library & Archives at the Heinz History Center. Robert Friday shared Jackson-Township historical preservation posted Jones & Laughlin Steel Corporation Soho Works at night in Pittsburgh. In July of 1859, Laughlin & Company, later to become Jones & Laughlin Steel Corporation, acquired land on the north side of the Monongahela River opposite Brownstown (currently the South Side neighborhood of Pittsburgh). In addition to two blast furnaces, called Eliza furnaces, some beehive coke ovens were built on this site, coke being necessary for the production of steel. It was common practice at the time to name blast furnaces after wives, daughters, and mothers. The name “Eliza” was chosen because it was a common name in both the Jones and Laughlin families. These furnaces, the second blast furnaces built in the Pittsburgh metropolitan area, began operation in 1860. Additional furnaces were added over the years so that ingot capacity at the Soho Works, also called the Eliza Works, reached 1,740,000 tons per year in 1920, and two million tons in 1930. The plant, which employed over 5,000 people at one time, closed in 1977 and the enormous blast furnaces at the site were razed in the mid-1980s. The Gulf Building in downtown Pittsburgh can be seen in the background. (Photo from http://images.library.pitt.edu/) |

The caption on this photo confirms that the building with just four smokestacks was an open hearth furnace.

|

| HAER PA,2-PITBU,62A- VIEW OF JONES AND LAUGHLIN FROM OAKLAND, LOOKING SOUTH. LEFT: HOT METAL BRIDGE; CENTER: OPEN HEARTH. - Jones & Laughlin Steel Corporation, Pittsburgh Works, Morgan Billet Mill Engine, 550 feet north of East Carson Street, opposite South Twenty-seventh Street, Pittsburgh, Allegheny County, PA |

There used to be four more smokestacks downstream of the ones remaining in the above two photos. (For orientation, the hot metal bridge is in the left background.)

|

| 𝗥𝗲𝗺𝗲𝗺𝗯𝗲𝗿 𝗪𝗵𝗲𝗻: 𝗣𝗲𝗻𝗻𝘀𝘆𝗹𝘃𝗮𝗻𝗶𝗮 and Ohio posted The Steel Mills of Pittsburgh, Pennsylvania Postcard! 1973 David Mancak shared |

Here the downstream OH has all of its smokestacks.

|

| Budhy Antho posted This is an excellent image of the J&L blast furnaces as referenced in a previous post. It shows the Hot Metal Bridge crossing the Mon' River to the J&L Southside Works. Second Avenue is visible in the lower left along with the Parkway East {376}. Note the pedestrian bridge that crosses 376 and Second Avenue. This was provided for the steelworkers as a quick/direct access to the furnaces from the parking lot and nearby hill top neighborhoods. Pittsburgh skyline in background. Courtesy: Anthony Cominotti/Steel Mill Pictorial Date: 1960s Peter A Mamula: The mills to the top right of those blast Furnaces & Hot Metal Bridge were the Strip Mills, Galvanizing, & drever furnaces! Stephen Walker: If you look to the top on the right by the parkway you will see the one remaining building. Metal Tech, still operating 24/7 galvanizing steel coils. Ken Mueller: Stephen Walker owned by SDI. John Rompala: Could you imagine working in that heat all day then having to walk Up all of those steps to go home? Real Tough Guys back then. [This is an impressive example of plagerism.] Jessica Van Giana posted This is an excellent image of the J&L blast furnaces as referenced in a previous post. It shows the Hot Metal Bridge crossing the Mon' River to the J&L Southside Works. Second Avenue is visible in the lower left along with the Parkway East {376}. Note the pedestrian bridge that crosses 376 and Second Avenue. This was provided for the steelworkers as a quick/direct access to the furnaces from the parking lot and nearby hill top neighborhoods. Pittsburgh skyline in background. Courtesy: Anthony Cominotti/Steel Mill Pictorial Date: 1960s Asmaru Acila posted with the same comment Daniel Noah posted with the same comment Jack Jack posted with the same comment Kajal Chauhan posted with the same comment Zhee Fawzhee posted with the same comment |

%20Facebook.png) |

| Newport Porter commented on Jack's post |

|

| Jackson-Township historical preservation posted Aerial view of the Penn Lincoln Parkway (Today I-376) when it ended at Bates Street. They had a mountain to get through to finish it to Pittsburgh in 1953 or so. The J & L (Jones & Laughlin) plant dominated the landscape at that time. The Hot metal Bridge can be seen at the lower left. (Photo from https://www.facebook.com/stuff.thatsgone/) |

|

| History's Mirror posted In the early 1950s, the Penn-Lincoln Parkway, now known as I-376, reached a temporary end at Bates Street in Pittsburgh. Completing the route into the heart of the city required a major engineering effort to cut through the hillside and urban landscape. The area presented significant challenges due to both the topography and industrial presence. One of the most prominent landmarks at the time was the Jones & Laughlin (J\&L) Steel plant, a sprawling complex that dominated the South Side riverfront along the Monongahela River. This facility was central to Pittsburgh’s identity as a steel-producing powerhouse and was tightly interwoven with the city’s infrastructure. In the lower left of the scene, the Hot Metal Bridge stands out, originally built to carry molten iron from one part of the J\&L complex to another across the river. The bridge was an industrial artery, essential to the operations of the plant. This era reflects a turning point in Pittsburgh’s transformation from an industrial center to a more diversified economy. The parkway’s completion helped shape the modern flow of traffic and accessibility in the city, symbolizing progress amidst heavy industry. The image captures a powerful moment in Pittsburgh's mid-century urban development. |

In this view of the Southside Works, we see that the downstream OH was built before 1931 and the upstream OH was built around 1931. (Note that four of the furnaces are still being added.)

|

| Doug Majka posted, cropped "More steel for America 1931-- Eleven new open hearth steel furnaces in the shadow of Pittsburgh's Golden Triangle will produce 2,000,000 tons of steel a year. Built by Jones and Laughlin Steel Corporation at a cost of $70,000,000, the new furnaces and accessory equipment are outlined in this photo. Defense Mobilier Charles E. Wilson tapped the first heat of 250 tons from one of the huge furnaces, Tues (Oct. 30), during impressive ceremonies attended by many of the nation's industrial, labor and government leaders." http://clevelandmemory.contentdm.oclc.org/digital/collection/press/id/10000/rec/17 |

Another view before the final four OH furnaces were built. The arch bridge downstream from the hot metal bridge is the Birmingham Bridge.

|

| Bob Ciminel posted J&L Pittsburgh works, pre-1946. Jim Ernst: It is amazing how large the “Pittsburgh” industrial region was ; starting upriver at Clairton to Homestead, to Hays, Southside, McKees Rocks, Neville Island, and down river to Ambridge and Aliquippa. Geo Howells: and was the #2 target of the nazi's if they invaded, dc was #1. Pete T. Kasich: This looks like only 1/2 of the Pittsburgh Works, Across the Hot Metal Bridge, on the other side of the river was the Coke Ovens/BiProducts in Hazelwood. I worked both, on the Coked Ovens and in The Open Hearth. John J. Chapman posted J&L, Southside |

This view is further upstream with the CSX/B&O Glenwood Railyard in the lower half. It provides an overview of the "J&Lbend" and its relationship with downtown Pittsburgh.

|

| Rollie Puterbaugh posted via Dennis DeBruler Image taken over the Glenwood Bridge {lower right} in 1971. It shows Hazelwood, the coke and blast furnaces belonging to J&L Steel along Second Avenue. You can also see the Hot Metal Bridge that took the pig iron from Second Avenue across the Mon' River to the Southside Works. Copyright: Rollie Puterbaugh |

|

| Jackson-Township historical preservation posted Jones & Laughlin Steel Mill located on the South Side in Pittsburgh on November 13, 1949. For the first time in 43 days, the giant Bessemer converters of J & L lit Pittsburgh's skies at night. The company settled its strike, but pig iron for the conversion wasn't ready for several days. A sight that was missing even longer were the big tows of coal, like the one making its way along the Monongahela River past the sprawling mill. This photo is by George Fiegal. (Photo and text from https://www.heinzhistorycenter.org/) Jackson-Township historical preservation posted again with the same comment. |

|

| Jackson-Township historical preservation posted Day and night views of the former J & L (Jones & Laughlin) Steel Plant in Pittsburgh in 1951. These photos were taken from "The Bluff" in Oakland. The beacon from the Gulf Tower can be seen in the night photo. |

|

| Bob McDonald posted One of the numerous construction pictures that I have of the J&L Southside Ultra High Power Electric Furnace Shop. Two 32 foot diameter 350 ton furnaces were installed in the late '70s. The photo below is of the #91 Furnace just before startup in May of 1978. Brian Olson: Putting one EAF in Campbell, OH with a Rokop caster would have made more sense. I was told a lot of the material produced on those South Side EAFs ended up at Aliquippa and Campbell as seamless tube. J&L Steel was the most profitable steel company in 1981 because of seamless tube. By 1985 they were bankrupt and that new EAF shop shut down and scraped. |

No comments:

Post a Comment