Their prep plant was in Cadiz, OH.

To put these shovels in perspective, Cat's largest wheeled loader, 994K, has bucket capacities from 25-32 cubic yards. The capacity of The Mountaineer's bucket was 60 cubic yards. [pinterest] I'm sure a wheeled loader, in conjunction with several mining trucks, can cycle a bucket load more than twice as fast as The Mountaineer could. And if one breaks, you can use a different loader while the broken one gets fixed so that mine production is not stopped.

Michael Davis These photos are from Dave Hopper's collection on stripmine.org.

Some comments on Stine's post of the Silver Spade talk about a "P&H 2800 Mark 3 with XP electrics" that is still running for Oxford mining near Cadiz, OH. Dakota Ginn provided three photos of that shovel.

Mark Benton posted two photos with the comment: "BE 120B loading a Dart 160 Ton Bottom Dump and a 120B loading a Euclid 50 Ton Bottom Dump."

The Mountaineer used the same undercarriage as the NASA Mobile Launcher Platforms, so it was a Marion 5760. The Tiger, a 46-A, also crossed at the same time.

I remember reading that when the government bought the land for I-70 in Ohio, they agreed that a coal mining company could cross the interstate once. I guess my source, or my memory, was wrong. This post says they could cross it ten times. However, I think they only did it once.

|

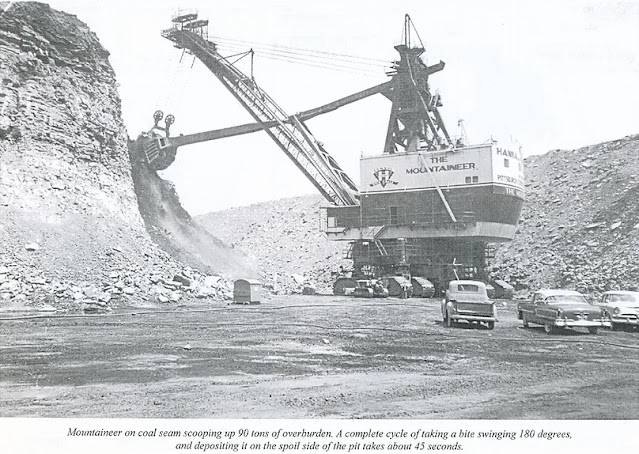

| Monroe County, Ohio (Memories) posted Ohio to Shut Interstate A Day for Shovel Crossing Jan. 1, 1973 The New York Times HENDRYSBURG, Ohio, Dec. 31—Two giant earth movers are taking their last bites from hills north of Interstate 70 in eastern Ohio and, weather permitting, are about to cross this major east‐west highway on temporary earthen dike to continue their foraging on 20,000 acres of coal‐rich land south of the freeway in Belmont County. Starting at noon Thursday, interstate traffic will he detoured for one and a half miles onto a section of old Route 40 near this small hamlet in the Egypt Valley section, 20 miles west of the Ohio River. Then at 2 A.M. Friday, Hanna Coal Company technicians hope to begin the movement of more than 10 million pounds of stripmine machinery across the freeway. Inching their way over the six‐foot‐high freeway harrier will he two mammoth shovels, the Mountaineer and the 46‐A. If weather causes any delay, the project will take place on Jan. 12, according to Hanna officials. This is believed to be the first time such an operation has taken place—closing of an interstate for a period of 24 hours—other than for repair work. The Mountaineer is a 5.5 million pound machine that removes earth and rock over the 100‐foot‐deep coal seam at the rate of 65 cubic yards, or 100 tons, per swing. It is Hanna's third largest strip mine shovel. The 46‐A, as its name implies, removes 46 cubic yards each time its bucket sinks its casehardened steel teeth into the overburden. It weighs 4.5 million pounds. The Mountaineer, with its 150‐foot boom, stands 147 feet high and would just fit inside the Houston Astrodome, The “house” where the machinery is mounted is almost as big as a three‐story, six‐family brownstone apartment. Hanna fills a 24‐hour period to transfer the shovels. Also within that period, the dike must be constructed, traffic detoured, the dike removed and the interstate reopened to traffic. South of the freeway, Hanna has coal holdings worth an estimated $8‐million to $10‐million. This large reserve was what triggered the move of the Mountaineer and the 46 ‐A shovel. In 1964 the state signed an agreement with the concern, subsidiary of the Consolidation Coal Company, allowing Hanna to cross the freeway 10 times within 40 years. The state did this rather than pay Hanna damages for loss of its coal when the interstate cut through the middle of the concern's holdings for about 10 miles. The actual crossing of the freeway will take from two to three hours, Hanna officials estimate. The machines can move at the rate of three miles an hour on level ground. In dismissing an action in the United States District Court in Columbus on Dec. 15, Judge Joseph Kinneary said that the blocking of 1–70 would be an “inconvenience” that would only slow traffic and not: stop it as long as a suitable detour was built. Hanna must pay for any damage to the highway, according to the court order. Hanna originally had intended to have its largest strip shovel, the Giant Earth Mover or GEM, across 1–70. The GEM weighs 14 tons and stands 20 stories high. An outcry by environmentalists and residents in nearby Barnesville, Ohio, apparently caused the concern to select the smaller machines for its first of 10 anticipated crossings. Ralph Hatch, Hanna's president, says that the GEM will make the crossing later in 1973 or early in 1974. The section due to be worked by the Mountaineer and 46‐A will be reclaimed under new reclamation provisions, even though the land was licensed for strip mining under the old and less restrictive law. In addition, Hanna has promised to work with residents of Barnesville, who have fought to have a “green belt” of land created around their community of 4,500. The town is directly in the path of the earth movers and its residents do not want their community to become the isolated hub in wheel of despoiled earth. Ohio State Department of Transportation officials will oversee the highway crossings, aided by members of the State Highway Patrol assisting with traffic movement. Harrison Coal & Reclamation Historical Park sharedHarrison Coal & Reclamation Historical Park shared |

|

| Eric Zimmerman posted Migrating Marions. I think this is in preparation for the I-70 crossing. Dennis Wade: These are the Hanna Coal Company's 60-E and 46-A shovels at the Egypt Valley Mine near Barnesville Ohio in January 1973. They just completed the crossing of I-70 and now deadheading another mile or so to their new areas in this photo. Operator Charles Busby commented that the rock was terribly hard to dig while ramping up out of there. |

|

| Mark Benton posted, rotated The Mountaineer and the 46A [the "Tiger", one of the four 5561s] preparing to cross Interstate 70 North of Barnesville, Ohio. The I-70 bridges and the hillside the shovels were on are just east of the Barnesville exit. Coal mined on the southside of I70 was hauled under the bridges back to the load out. Monte Lewis: We covered the road with crushed limestone out of Consol’s limestone plant in Cadiz Oh. I dumped the very first load on the Interstate. Michael Mallernee: Layer of straw then dirt then oak mats road was unharmed crossed at night when there was less traffic But traffic was backed up for miles from people stopping to see the shovels up close. Jason William Geis: Didn't they lay the dirt, cross the highway, and have it cleaned up overnight? |

|

| Mark Benton commented on Monte's comment |

|

| Alex Schafer commented on Mark's post I live right off the Barnesville exit this is an old picture just south of 70. |

|

| Eric Zimmerman posted So here we see the aftermath of the Mountaineer’s boom collapse (1973?). Can somebody who is intimate with the event tell us exactly what failed? What was the initial failure that led to all this mayhem? Just trying to clarify in my mind. R Dale Davis: A huge Rock let loose as the bucket after moving up thru the hi wall and bucket was filled practically to capacity’s of 65 cu yds the extra weight of toward the top let loose over whelming the cables and collapse of gantry and twisted the boom. It was if I remember correctly about $750,000 repair and down 3/4 months . I have the initial estimate of the cost and time to put back together. Eric Zimmerman: R Dale Davis very well and thank you for the details. I am simply observing the photo and I was trying to imagine what forces it would take to tear that gantry apart. That is pretty much the foundation and there’s the peak torn out. Kind of surprises me that the boom stays didn’t fail prior to the gantry. But I suppose the crowd rack could have been jerked right out the front precipitating the gantry peak being separated. Jay Wilson: R Dale Davis Let me bring this up. These shovels were production machines, setting all kinds of records for the amounts of material moved. And this shovel had a few years on it, steel was getting stressed and weakened. Think maybe some cracks here and there were overlooked to keep up production and it just caught up with them. Same deal on one of the B-E 3850B shovels. Back leg supports gave loose and it all fell forward. Same excuse of hard digging and rock overloading the bucket. Makes you wonder anyway it happened. Bill Grimes: I was working on the hill running the drill when it fell watch it fall it was cold A big rock in the bucket it was full everything fell into the pit no one got hurt very lucky everyone worked to get it put back together and running again lot of hard work with good men @ Foreman John Moore: I don’t really know what happened. My guess was the high wall came down. We worked several months on rebuilding back to normal. Never was in production after rebuilding. Sad story for all employees at Egypt Valley mine. R Dale Davis: John Moore this happened in 1973 and after repair was placed back in production till January 1979 after a rebuilding of rails and new rollers under house and extensive maintenance and repair during the fall of 1978. It ran one shift in January 1979 and was parked near Fairview never to operate again. |

|

| Ryan Keesey commented on Eric's post, rotated |

|

| Ryan Keesey commented on Eric's post |

|

| Harrison Coal & Reclamation Historical Park posted Mountaineer one of the world's biggest electric shovels. Harrison Coal & Reclamation Historical Park shared |

|

| Rob Mihalco posted The Mountaineer (Consol Coal) Bill Welsh: My grandfather "Preach" Manbeck was an operator of this shovel for many years. They only had three men operate it and the shovel worked 24/7. Grandad worked 7 days a week for 11 YEARS !!! One midnight shift he snuck me to work and I sat with him on the shovel while he mined coal. One of the favorite memories of my life. Sandy Shelton: Hey Bill remember when they had the "opening" with pictures and news coverage. Uniforms had been ordered from Dad and they weren't' in so Mom and Dad drove to Indiana and back and arrived with them late the night before the official "opening" Terry Howell: My dad worked on it till they shut it down. He ran dozer under it, then ground oiler, then top oiler, and operated to relieve operator but they changed bid process just before he got full time operator job. Harrison Coal & Reclamation Historical Park shared |

|

| Chet Kresiak posted 1961, The Mountaineer huge steam shovel, Cadiz Ohio, coal mining pit. Jim Kratzer: It was an electric shovel, not steam. Daniel Krähenbühl shared |

|

| Longhorns Head To Tail Store posted The 60E Mountaineer was one of the largest shovels every built and was used in Belmont County for strip mining. When it came to the end of it's days on January 26, 1979 it was parked in what is called the Nevada pasture of Dickinson Cattle Co. It was a local curiosity for 10 years and then torched and scrapped June 1989. Only one piece of a cog remains at DCC. Do a tour of DCC this Summer and see where a lot of history was dug up. Dennis Wade Photo. Harrison Coal & Reclamation Historical Park: Actually used to uncover coal in Harrison and Belmont counties. The Mountaineer was erected near Cadiz in the area known as Georgetown. From 1956 to 1962 it was the world’s largest shovel . Open house was January 25-27, 1956. It was constructed 1 mile east of New Athens near State Route #519 and Georgetown Road. Operated in Harrison county till 1967 and deadheaded to Egypt Valley. Crossed I-70 in January 1973 along with the “A” Marion #5561 aka “The Tiger” which in 1976 was sold off to Muskingum Mining William Taylor: Harrison Coal & Reclamation Historical Park my Dad was operating the Mountaineer when it crossed I70 in 1973. Harrison Coal & Reclamation Historical Park shared Harrison Coal & Reclamation Historical Park shared |

|

| William Taylor commented on the above post |

|

| Dan Smith posted From Jan. 1973, My dad Dan Smith Sr. was a cableman on the smaller shovel, The 46A,"The Tiger". |

Steve Moore posted four photos with the comment: "A few pictures that my dad John Moore had of the Mountaineer and the 46A after they had crossed I-70 on January 4,1973 The shovels are setting on what was at that time US 40 in these pictures."

Harrison Coal & Reclamation Historical Park shared

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

Susan Taylor posted two photos with the comment: "These photos of the Mountaineer strip mining shovel don't come close to illustrating the true size of these monstrous machines. Many pics of the Mountaineer and others owned by Consolidated Coal (Silver Spade, Gem of Egypt) in Eastern Ohio can be found online or at West Virginia History OnView | WVU Libraries (wvhistoryonview.org) Generations of those who worked on these gigantic shovels are still around to tell many stories. Photos appear to be circa late 1950s."

[As a comment suggested, search with "shovel mountaineer".]

Harrison Coal & Reclamation Historical Park shared

|

| 1 |

|

| 2 |

|

| Rick Borland commented on Susan's post A pic of the Mountaineer my dad took circa 1957. |

|

| Rachel Frew commented on the above share If you enlarge this photo, you can see the size of the men at the base of the machine. One of my father’s images. |

|

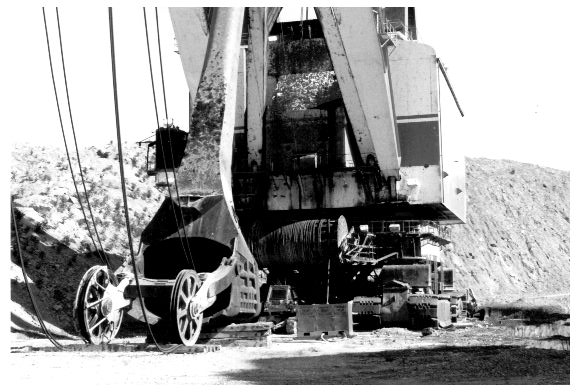

| The search result has a lot of photos of people standing in the bucket, but I like this one in terms of helping to understand the size of the shovel. |

|

| Digitally Zoomed This is the first time that I have seen one of the drive shafts. |

Harrison Coal & Reclamation Historical Park added eleven photos with the comment: "Photos provided by Jeff Waid: The Mountaineer. All slides taken by my Grandfather Ralph J. Hockensmith in 1966. Cadiz, OH."

Michael Diane Wright: I was in reclamation and worked in front of it pulling topsoil.

Jamie Kelich: Refresh my memory what was the purpose of the tube stack they installed later on?

Harrison Coal & Reclamation Historical Park: Jamie Kelich vent hot air generated by the electric motors. It was removed when it was damaged when the boom collapsed in 1971. [Actually, the stack was fresh air inlet.]

Harrison Coal & Reclamation Historical Park shared

Harrison Coal & Reclamation Historical Park shared

Harrison Coal & Reclamation Historical Park shared

|

| 1 |

|

| 2 |

|

| 3 |

|

| 5 |

|

| 5 |

|

| 6 |

|

| 9 |

|

| 10 Joe Dewitt: How wide of a cut did it take? Jay Wilson: Joe Dewitt Probably not much wider than the crawler stance. Not with no spoil room on that damn inside curve. Problem for a shovel or dragline. |

|

| 11 |

|

| Eric Zimmerman posted We’ve all heard of synchronized swimming. How about synchronized shoveling? The GEM and Mountaineer. |

|

| 1 of four photos added by Harrison Coal & Reclamation Historical Park Hanna Coal Mountaineer and its shovels [These are the extra dippers for the Mountaineer.] Harrison Coal & Reclamation Historical Park shared |

|

| Brandon Willis shared, also PopHistoryDig from Life magazine in the 1950s Marion Power Shovel Co., The Mountaineer, built '55-'56. 16 stories tall. This started the super-shovel era. Its shovel could handle a 100-ton payload. Jon Timothy Wilkins The Marion Power Shovel Company went on to build NASA's 2 crawlers that took every Saturn V Apollo Rocket and every Space Shuttle to their launch pads....they will be used in the new SLS rocket series that will return to the Moon and then on to Mars. |

|

| Mark Flood commented on Brandon's share [This photo provides scale for the size of the bucket and tracks.] |

|

| Harrison Coal & Reclamation Historical Park posted The Mountaineer (Marion 5760) was the largest mobile land machine every produced. It was the first of the “super strippers” to work in coal fields around Cadiz, Ohio. The Mountaineer was assembled in 1955. The shovel worked in the area from 1956 until 1979. At 16 stories tall and weighing 2750 Tons, this machine supposedly started the super shovel era. Hanna and its successor Consol would later have several more of these types of shovels prowling the southern Ohio coal fields in Harrison and Belmont Counties. Denny Brandal: This looks like the Willis McCaleb photo shoot. He was the NKP railroad company photographer and climbed the boom to shoot the Berkshire down through the open bucket. 1955, NKP (ex-W&LE) locomotive 819. Richard M. Gaskill: Seems we have a challenge to the largest ever built "Marion 6360, also known as The Captain, was a giant power shovel built by the Marion Power Shovel company. Completed in 1965, it was one of the largest land vehicles ever built,exceeded only by some dragline and bucket-wheel excavators.It was built in 1965 Length 97 m (319 ft) Width 27 m (88 ft) Height 64 m (210 ft) Weight 12,700 t (28,000,000 lb) The only Marion shovel that compared (in size and scope) to "The Captain" was the Marion 5960-M Power Shovel that worked at Peabody Coal Company's (Peabody Energy) River Queen Surface Mine in Central City. It was named the "Big Digger" and carried a 125-cubic-yard (96 m3) bucket on a 215-foot-long (66 m) boom. |

I've been waiting for William to finish this project, but the comments on this post about self-maintenance are worth saving.

William Oldani posted three photos with the comment:

This has been a Really enjoyable Project, the Marion 5760-M. First of the Super Strippers introduced in 1956 the Year I was Born!It's Really interesting to see how the Mining Monsters Evolved.Since the Mountaineer was a First, the Engineers focused on access and Maintenance since Large Lift Cranes were not a major item components on Mining Properties. The Mountaineer had No Less than 6 external Hoists rated over 15 tons! Something that would all but disappear over the next 2 decades.In short, the Mountaineer carried a lot of extra weight and design considerations for these Fixtures.I still have the Dipper to complete and then I will post comparisons with Other Mining Icons!

Jay Wilson: Interesting fact about the cranes for service. Seems like Marion over engineered lots of components of machine that were to be the largest for the time.

Dennis DeBruler: Thanks for including the man at the top. It not only help emphasize how big the shovel was, it drew my eye to one of the hoists.

|

| Cat 994K |

|

| PopHistoryDig "Generally it is economic to strip mine when there is a 20:1 ratio of overburden-to-coal seam." [This article has a lot to say about the evils of strip mining. One of the impacts of strip mining is that it removes the people from the land because their property has been bought and their homes are destroyed.] |

.jpg) |

| PopHistoryDig The shovel helped make the land bridge across the interstate. The Tiger (46 cu yd) and Mountaineer (65 cu yd) shovels crossed the Interstate at 3mph. The GEM of Egypt (130 cu yd) did not cross because of the bad publicity it had received as a symbol of the evils of strip mining. "The crossing required a rerouting of traffic off I-70 for approximately 1¼ miles. Temporary entrance and exit ramps in both directions were constructed, connecting with State Route 800 onto which traffic was routed for a mile or so, until it could return to I-70. Uniformed flagmen were stationed to direct traffic through the re-routing. To protect the highway pavement, a special gravel and earthen land bridge was built across I-70 over which the Hanna shovels crossed. At least six feet of crushed stone and earth was used for the land bridge and heavy wooden mats were also placed over the crushed stone and earth. Sensors were also placed beneath the highway surface to test for any stress on the roadway. "A fleet of some eight bulldozers worked around the base of the big shovels, helping to shape and stabilize the land bridge ahead of the crossing. The transit of the big shovels began at noon on January 4th, 1973. Under the permit, Hanna was allotted a period of 24 hours to move its equipment, and officials at the company had estimated it would take from two to three hours to make the actual crossing. However, the crossing was made ahead of schedule and was actually completed by 6:30 pm that day." |

Marion made more than one 5760.

|

| MachinePorn Marion 5760 “Big Paul” stripping shovel, nearly the same as “The mountaineer” except it was owned by Peabody coal, for more info, go to historic stripping shovels on FB that’s the only place I know of where direct info comes from, the people there ran these machines. |

|

| Mark Benton posted The Mountaineer and the Gem passing each other in the pit. मनिष फेवाली राना मगर: Mountaineer was half the size of Gem? And which model was mountaineer, 5760 or 5761? Mark Benton: Mountaineer had 60 cy bucket Gem 130CY. Won't swear to model number. Matthew Ethier: Where these diesel or electric? Gibson Smith: Matthew Ethier electric |

|

| Eric Zimmerman posted Hanna Marion meet up. Myron Dudenbostel: 5561's..... R Dale Davis: Thank you for sharing this!This was when the “B” shovel AKA “Green 🐝 Hornet” came out of erection pit in July 1947 and on its way to its working field passed in the working area of the “A” shovel AKA “ The Tiger” which was place in service in February 1944. Both was originally equipped with 35 cubic yards buckets . Later convert to 40 yard in the 1950’s and 46 yards later. Jay Wilson: Machine on the right has no stick or knuckle on it. Jack Walters: Jay Wilson Looks like the crowd sticks are there. Probably changing out the bucket. Some were a flat bottom and some had a curve to them. We had The A Machine break the dipper handle once. There’s a safety cable inside the handle to keep from loosing the bucket or at least slow it down. R Dale Davis: Jay Wilson they are both Marion #5561 with 36 cubic yard buckets and machines identical except the boom one is solid other is lattice. |

|

| William Oldani commented on मनिष फेवाली राना मगर's comment 5760, the First Marion Model considered to be a Super Stripper Class. |

I don't know if these photos are of the Mountaineer, but all of the Marion 5760s would probably look the same except for the paint job.

Barry Thornberry posted 20 photos with the comment: "Marion 5760."Michael Davis These photos are from Dave Hopper's collection on stripmine.org.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| 11 |

|

| 12 |

|

| 13 |

|

| 14 |

|

| 15 |

|

| 16 |

|

| 17 |

|

| 18 |

|

| 19 |

|

| 20 |

The shovels were assembled in the Gerogetown facility near Cadiz, OH, and worked their way south.

|

| PopHistoryDig via Dennis DeBruler |

Five of many photos from TheCoalMuseum:

|

| 1 |

|

| 2 |

|

| 3 |

|

| Mark Benton posted 550B Consol Egypt Valley Mine. Jay Simeral: How many shovels did Hannah consol own. Mark Benton: In Ohio: Gem, Spade, 60E, 46A, 46B, 46C, 46D, 550B Ken Lahmers: The Trail Blazer !! Have seen dozens of photos of the other Consol eastern Ohio shovels, but photos of the Trail Blazer are rare.... |

|

| Thomas Farwell posted Back around 1988-89 I saw this machine from far away. Being in the mine equipment erection business my curiosity got the best of me. Was finally able to get close enough. The machine had been sitting for quite long. Lots of rust and windows boarded up. The circle in lower right is my buddy standing by it. He is 6’2” so used that for dimension. Can anyone ID this for us. We were in SE Ohio. Love this site and Thanks for any help. R Dale Davis: It is the Marion #5561 46-C aka “The Wasp” in production August 1947 originally 36 cu. Yd bucket later changed out to 40 and finally 46 cu yd. Operated mostly around Harrison county and parked in 1982 near the intersection of State Route 519/ US Route 22. Contract out in 1988 for scrap.originally the color in 1947 was a greenish-grey changed to Red/ white in the late 1960’s and in 1975 DuPont purchased company and color of all the shovels was changed to this orange/ yellow. Hanna Coal started surface mining in 1939-40 with two steam shovels moved from the iron ore mines . First 225 BE and 300 Marion. Next was 550 BE then first of four #5561 , “A” the Tiger, “B” The Green Hornet or later the Bee, “C” The Wasp, “D” The Groundhog. Next was The 60E “Mountaineer and Silver Spade & GEM. |

I assume by "B shovel" he means the Green Hornet at this mine.

|

| James Stine posted In this Archive photo, we have the 5561, B shovel. This was the last of 17 Marion Type 5561 shovels built. This machine carried a 120 ft boom and a 45 yd. dipper. I am looking for additional photos and the stories from the folks that worked around this and the other 5561 and 5323. Harrison Coal & Reclamation Historical Park shared |

|

| Eric Zimmerman posted Hanna’s Green Hornet |

|

| Eric Zimmerman posted R Dale Davis: That is one of Hanna Coal Company Marion #5561. Look like early 1950’s and “B” the Bee 🐝 or “C” shovel The Wasp |

Some more information on the four #5561 shovels.

|

| Harrison Coal & Reclamation Historical Park posted 50 cubic-yard shovel of Hanna Coal Company at Georgetown No. 12 Mine: These electric shovels are used to remove the earth and rock overburden from the coal seam. In a month's time, they will each remove as much as 1,6000,000 cubic yards, or some 2,400,000 tons. If this material were to be loaded into open railroad cars, it would fill some 48,000 of them. SHOVEL SPECIFICATIONS: DIPPER CAPACITY 50 Cubic yards, Total Height 130 feet, Total Length of Boom 120 feet, Length of Dipper Handle 60 feet, Lifting Power 400,000 pounds, Approximate weight 3,500,0000 pounds (1,1750 tons) 4160 volts of electric power is delivered to the shovel by flexible cable. The shovel has eight electric motors: 2- 425 H.P. Hoisting Motors, 3 - 125 H.P. Rotating Motors, 2 - 75 H.P. Crowding Motors, 1- 1,500 H.P. Driving Motor. The shovel "floats" on four electrically controlled hydraulic cylinders, which keep it absolutely level while operating. The shovel crawls under its own power at a maximum speed of 31 feet per minute. It is capable of climbing grades steeper that 20%. The actual operation of the shovel is controlled by one man, who uses 2-foot treadles, 2 hand levers, and 1 whistle cord. One other control is used when moving the shovel from place to place. In addition to the operator, one oiler is used for lubrication and minor repair work, and one shift per day, a ground oiler is employed. A bulldozer works with the shovel at all times to push fallen earth and rock to where it can easily be reached by the shovel. The control on this machine is highly developed. Notwithstanding the weight handled and the lifting power available, the operator has, through the controls, a very delicate "feel" of the machine in all its functions, and he can with extreme rapidity and great accuracy, maneuver all of its motions. The depth of overburden which these shovels remove averages 80 feet. From the Ellen McGinnis Family donated by Nancy from Nancy's Florist. The first A shovel aka “The Tiger” was built in production in February 1944. B the Bee in 1947 followed by the D Geoundhog 1949 & C The Wasp in 1950. All originally had 36 yard changed to 40 yard buckets and eventually 46 Cu. Yd machines. 5561 model from Marion . A & Mountaineer only shovels to cross I-70 in January 1973. A sold off to Muskingum Mining 1976. Harrison Coal & Reclamation Historical Park shared |

|

| Ohio Department of Transportation Eastern Ohio District 11 Tom Barnett: My favorite shovel, the 46D or the Groundhog. Stripped Cherry Valley and West Farms. Coal went over to Piney Fork which was served by the New York Central Railroad’s Alliance Branch. I took quite a few slides of it working in 1970. It finished up around 1979 and later scrapped. Harrison Coal & Reclamation Historical Park shared Jack Walters: Marion 5561 One of four 5561’s Hanna / Consol had. Daniel A. Mitchell: There were three of these Marion 5561 shovels, named, "A", "B", & "C". The shovel shown here was called the "C-shovel", aka "The Groundhog". It, and the "B" shovel, the "Green Hornet", had lattice booms. The "A" shovel, the "Tiger", had a more solid-appearing girder boom. The only big stripping shovel I ever got to see running was the "A" shovel. Harrison Coal & Reclamation Historical Park: Daniel A. Mitchell Hanna had four. Tiger, Green Hornet, Groundhog, and Wasp. Brad Burrough: How much bigger was the Mountaineer? Jerry Lacy: Brad Burrough I’m pretty sure that the mountaineer had about a 65 yard bucket. I believe that the 5561s usually had about a 40 yard bucket. Harrison Coal & Reclamation Historical Park: Brad Burrough The Hanna 5561 shovels was 40 yards. Hanna did do a upgrade to 45 yards. Not sure which ones got the upgrade. The Mountaineer was originally 60 yards and later upgraded to 65 yards. |

|

| Ryan Keesey comment on the first photo in a post This was the “46-C” the wasp at 519 & 22 |

Hanna was bad at doing reclamation, so the road they made for the shovel should be visible for years after the move was made. The white line down the right side below I-70 is OH-800. It looks like the road made for the move went a ways West and then went back East.

|

| EarthExplorer: May 5, 1975 @ 78,000; AR1VDLT00050176 |

|

| Susan Morris Adams posted This is a close-up of the "dipper" or bucket on a 50 Cubic Yard Electric Shovel that was at the Georgetown No.12 Mine of Hanna Coal Co. In a month's time it could remove as much as 1,600,000 cubic yards, or some 2,400,000 tons of earth and rock overburden from the coal seam. If this material were to be loaded into open railroad cars, it would fill some 48,000 cars. The 1,750 ton shovel this dipper was attached to was operated with 4,160 volts of electric power delivered to the shovel by flexible cable. The shovel was controlled by one man, who used 2 foot treadles, 2 hand levers, and 1 whistle cord. One other control was used when moving the shovel from place to place. Dean Littman: I don’t think this is the Mountaineer. The Mountaineer wasn’t built until 1955 and it had a bigger scoop. This may have been the shovel Consol called the Groundhog it was similar but smaller. Gary Ludwig: Probably the Bucyrus/Erie A or B. They operated in the areas between Georgetown and New Athens, all the way up to the early 80's. My Father-in-Law was on the "Bull Gang"that repaired and maintained these shovels. Tom Barnett: Question- Would this be the A, B or C shovel? I understand A B C and D were forerunner to the Mountaineer, Spade and Gem? PS: I’ve got a great slide show of the D working the West Farms 22 mine near Smithfield and Piney Fork. Trying to accurate pinpoint which shovels worked where? Dennis Wade: 46-B shovel of Georgetown #12 Mine. Pit foreman Chas. Fulton is standing by the pickup truck. This is also not the 50 yard bucket. The 50 yard dipper had a very distinctive look to it and it wasn't in service very long too heavy. Bucket #8 was one of the regular 46 yard buckets used on all the 5561 machines Gary Ludwig: Next question: 46-A, “Tiger,” 46-B, “Green Hornet,” 46-C, “Groundhog”. 46-D, ? Ron Stinard: Gary Ludwig The 46-D mine was West Farms the D nickname I believe was the Wasp ,, but during the time I was there in the 70’s , I never heard any one call any of the 46 machines by these nicknames.. Any communications or meetings all anyone called them other than the mucker, was the A B C or D ,, Mountaineer , Gem or Spade ,, never knew the 46 machines had these names until Facebook came along ,, LOL [Several comments discuss were the various 46 shovels worked.] John Forro: I wonder where Georgetown is located? Gary Ludwig: John Forro The coal field Georgetown is on US 250 about halfway between Harrisville and Cadiz (Harrison Co.). I grew up nearby. Harrison Coal & Reclamation Historical Park shared |

|

| Dennis Wade commented on Susan's post |

| |

|

| |

|

| |

|

|

| Dan Smith posted Dad took this from our rooftop in 1966, as the Hanna Coal Co. shovel, "The Tiger", was stripping it's way up behind Flushing. He was a cableman electrician on that shovel. Harrison Coal & Reclamation Historical Park posted |

|

| Harrison Coal & Reclamation Historical Park posted The Mountaineer: Imagine a machine that stood as high as a 16-story building that was still able to move by its own motive power. A machine that had an operating weight of 2570 tons, swung a 65 cubic yard bucket that took 100 ton bites of earth and rock, and moved it over the length of a football field to place it on top of a giant spoil pile. The official designation of this stripping shovel, the correct name of such a type of machine, was type 5760 and was manufactured and erected by the Marion Power Shovel company during 1955 / 56 near Cadiz, Ohio. This behemoth was better known under its unofficial name, the Mountaineer. Seen here with The GEM of Egypt. Harrison Coal & Reclamation Historical Park shared Harrison Coal & Reclamation Historical Park shared Paul Pillau: Great picture! I was unaware that they were ever that close to one another. |

|

| Belmont County Tourism posted Did you know? The GEM of Egypt was a power shovel used for strip mining. Built in 1966, the machine had worked in the Egypt Valley coalfield near Barnesville. The GEM acronym stands for Giant Earth Mover or Giant Excavating Machine. It was one of only two Bucyrus-Erie 1950-B shovels built. The machine began work in January, 1967 for Hanna Coal, and was later purchased by Consolidated Coal (CONSOL) in "Little Egypt Valley”. The machine was parked in 1988 and finally scrapped in 1991. Parts of the shovel were used to keep its twin, The Silver Spade, operating until it too was retired. (Image from Pinterest). Harrison Coal & Reclamation Historical Park shared |

|

| Pat Davis posted I see all these "like if you remember" pictures. But, how many of us "Ohio people" remember the Gem of Egypt? Maybe I can get 200 likes. Never had that many before. Would love to see what that many looks like. OK Pat, quit rambling and post the darn picture! lol Enjoy going down memory lane. Harrison Coal & Reclamation Historical Park shared |

|

| Ryan Singhas posted My dad Carl on the right. William Oldani: That's the Gem's maximum fill bucket! 130 Yds. Harrison Coal & Reclamation Historical Park shared |

|

| Barnesville Enterprise posted Fifty years ago this [Jan 19, 2017] weekend [1967], traffic was backed up Stillwater Creek in Egypt Valley to Route 40 and beyond as area residents got their first look at Hanna Coal’s new Gem of Egypt coal shovel. The Gem weighed 14 million pounds, was 178 feet high and was the world’s largest electric shovel at that time. It could dig up 400,000 pounds of earth with each bite of its 130-cubic yard bucket. Once the fields north of I-70 were consumed, the shovel was supposed to cross south to Barnesville. Instead it was moved north to Harrison County where it was idled in 1989 and dismantled two years later. Harrison Coal & Reclamation Historical Park shared |

Harrison Coal & Reclamation Historical Park shared four photos with the comment:

These would of been taken between New Athens and Fairpoint, Ohio along Ohio Route 9.She started life in Egypt Valley in Belmont County and was named The Gem of Egypt. Gem meant Giant Earthmoving Machine. She later left Egypt Valley and was renamed to Gem. She later moved into Harrison County and later returned to Belmont County finishing out her life.Photos donated by Tom Grunder of Canton, Ohio

|

| 1 |

|

| 2 |

|

| 3 |

|

| Harrison Coal & Reclamation Historical Park posted The Silver Spade Harrison Coal & Reclamation Historical Park shared |

|

| Mark Benton posted Terry Mueller: Hauled coal out of the highwall mine at cadiz were the spade was working one day in the 2004 or 2005 it was Kool watching it work then I heard it broke down was to much to fix it. Timothy Ling: Terry Mueller Heard the swing circle went bad. Too expensive to repair. Mark Benton: As per B-E both 1950B shovels worked well beyond their engineered life expectancy. |

|

| Mark Benton posted Closer view of Silver Spade. |

|

| Stine James posted The first Bucyrus-Erie 1950-B shovel, or better known as the "Silver Spade". The machine starting to work in late 1965, is just over a year old in this photo with the 200 ft. boom and 105 yd. dipper. She was the last stripping shovel to work in the world, and was scrapped down in Feb. 2007. Photo courtesy of Coal Age. Harrison Coal & Reclamation Historical Park shared |

|

| 1 |

|

| 2 |

|

| 3 |

|

| James Carl Trivett III commented on Stine's post In this picture you can see where the band has pulled apart. |

|

| Florian Damin commented on Stine's post |

|

| Ruth Dave Williams commented on the above share Before she was born July 1964 |

|

| Mark Benton posted 61R Drill Jim Clark: The first 61-R drills made was for the 3850-B Lot#1, Peabody Coal Company, Sinclair Mine. We had the first 2 ever built, constructed during the erection of Big Hog. They both started up about the same time (Spring/Summer of 1962) ahead of the 3850 which started up around October of that year, drilling 15 inch diameter holes 3 shifts a day 7 days a week. Once they got far enough ahead of the 3850, one of the two drills was put down on the parting between #11 and #12 seam, but eventually a Marion Mark I, twin mass drill was used for that parting. We called the Marion Mark I “Mickey Mouse”. |

|

| 1:46 video The Silver Spade's last pass, 2:00 pm, April 9, 2006. She was digging her way out of the hole to be retired, with the possibility of becoming a museum, but it was discovered that the roller circle had broken again. It was finally decided to cut her up on the spot. This was shot with an early digital camera. Recently we found a big box of Sony Digital 8 tapes, and have a few of them up, including the Silver Spade and a very neat big Bucyrus 50B steam shovel.. |

|

| 5:27 video The Silver Spade was a giant power shovel used for strip mining in southeastern Ohio. Manufactured by Bucyrus-Erie, South Milwaukee, Wisconsin, the model 1950-B was one of two of this model built, the other being the GEM of Egypt. Its sole function was to remove the earth and rock overburden from the coal seam. Attempts to purchase and preserve the shovel from Consol to make it the centerpiece of a mining museum exhibit for $2.6 million fell short, and the shovel was dismantled in February 2007. [At 2:08, they show it crossing a road.] |

The Silver Spade crossing RT-519:

|

| 6:48 video @ 1:08 |

And if that wasn't enough Silver Spade action, here is two hours!

Jamie Kelich posted four images with the comment: "Gem of Egypt, Silver Spade, Mountaineer & other shovels."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

Mark Benton posted two photos with the comment: "BE 120B loading a Dart 160 Ton Bottom Dump and a 120B loading a Euclid 50 Ton Bottom Dump."

|

| 1 |

|

| 2 |

Bruce Draher posted six photos with the comment: "Mountaineer photos my dad took."

Jay Wilson: All picture proof they stripped in an outside turn. For more spoil room. Smart engineering on Consols part.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

.jpg)

No comments:

Post a Comment