As the title implies, the corporate history of this plant is complicated, especially the string of bankruptcies starting the in 1980s. Of note, National Tube was a division of US Steel. And today's Republic Steel is not the one that was in Chicago and other towns. See AbandonedOnline for the details.

I didn't notice the Huletts in the above image until I saw this post.

Tin Stackers -- Boats and people of the Pittsburgh Steamship Company posted three photos with the comment: "Here are a few photos of the unique Huletts that were once located at the U.S. Steel National Tube plant at Lorain Ohio. There were 2 generations of Huletts at this dock. An old view from 1907 shows the original 4 10 ton capacity units, while the other 2 scenes are of the later 20 ton capacity machines, which were built in early 1945 to replace the older units. The color shot is from June 1973. From my collection."

|

| 1 |

|

| 2 |

|

| 3 |

|

| George Frigm posted A picture of the last [Kelly]Bessemer Furnace built in the US in 1949 @ USS Lorain OH. Production of Bessemer Steel ended in 1968 after about 115 years. Interestingly about the same time line as the Open Hearth Furnaces in the US. Michael Kennard: Great pic. There were three here. You can see the trunion gear boxes for the other two vessels not visible in the shot. There are photos of all three in blow around. Also, the Blast furnace that fed hot metal to them is in the background. Joe Barron: The introduction of the Basic Oxygen Process (BOP) eliminated the need for the Bessemer as well as the Open Hearth as the BOP wound blow out the carbon like a Bessemer and also enable you to refine the metallurgy like the Open Hearth |

|

| Doug Majka posted image from https://clui.org/ Greg Rodger: What is casted from a blast furnace? Is it what ever the company makes? Our MeltShop melts scrap and internal scrap to cast billets. Doug Majka: Greg Rodger iron ore, coke and limestone makes liquid molten iron and then they have to add scrap steel and blow it with oxygen to make liquid steel they are making hundreds of tons at a time so they are not making castings. Owen D Magargee: What mill is this? Doug Majka: Owen D Magargee used to be us steel national tube. now it's called republic and owned by mexicans. the pipe mills are still owned by US steel but they haven’t run in years. |

|

| safe_image for Drone Video: The Lorain Steel Mill |

|

| Michael Watchorn posted John Amador: Lorain National Tube Company, Pearl gate |

|

| 𝗥𝗲𝗺𝗲𝗺𝗯𝗲𝗿 𝗪𝗵𝗲𝗻: 𝗣𝗲𝗻𝗻𝘀𝘆𝗹𝘃𝗮𝗻𝗶𝗮 and Ohio posted National Tube Division Of US Steel • 1978 Postcard Lorain, Ohio Darrin Kocjancic: That isn't the '70's. By the cars, it's probably the late 50's, or early 60's. [Was 1978 the postmark?] |

|

| 3D Satellite |

|

| Birds-Eye View |

An earlier article, with another picture of the plant, explains this plant's proximity to railroads is important because it will use raw iron ore pellets that are made in Reynolds, IN. (That is also an operation that was shutdown, but that is now being restarted.)

Update:

|

| John Groves posted |

Drone photo by Bubba Dubs: Republic Steel's Mexican owner, Grupo Simec reports that Lorain No.4 BF has a book value of zero, but is still held in reserve with confidence that it will be restarted in the future. Wishful thinking?

Republic Steel Inc.

Republic Steel (formerly Republic Engineered Steels), owned by Mexican steelmaker Group Simec Guadalajara, incorporates the remnants of the steelmaking and SBQ bar rolling facilities of the former LTV Steel, Bethlehem Steel and U.S. Steel integrated giants.

The facilities are located at Canton and Massillon in Ohio (originally Republic Steel), Lorain in Ohio (originally U.S. Steel) and Lackawanna in New York (formerly Bethlehem Steel). The steelmaking remnants of the Bethlehem Johnstown PA plant were also merged into the Republic Engineered bar assets in 1999 but shut down by 2000.

The convoluted history of these remnant plants over the past three decades has been difficult to document, but here is my history and current status of these plants.

THREE IMPORTANT QUESTION – HELP REQUESTED

1) Can anyone help with details of the continuous caster installed by Bar Technologies in 1996 or 1997 at the former Bethlehem Johnstown plant?

2) Can anyone confirm what year USS/KOBE installed a tank vacuum degasser at the Lorain melt shop? I think possibly in the late-1990s.

3) Can anyone help clarify this apparent contradiction from two key sources: the 2022 AIST survey of North American EAFs lists Canton as having one 220 net ton upgraded EAF and also one old 100 net ton furnace (idle since 2020). But the Grupo Simec 2022 Annual Report says Canton has 2 x 200 ton EAFs.

Republic Steel Central Alloy District, Canton Works, Canton OH

Established BF 1916, OH 1904, EAF 1914, mills 1904.

BF closed late 1970s, OHs closed late 1960s – all obsolete, replaced by expanded EAF alloy and stainless steelmaking (9 EAFs - 1.5 Mtpa).

Established 1904 by United Steel Company, renamed United Alloy Steel Corp. in 1916, merged into Central Alloy Steel Company 1926 then merged into Republic Steel in 1930. Republic Steel in 1984 merged with Jones and Laughlin Steel to form LTV Steel. Major expansion by 1920 included two OH shops, first 3 EAFs, primary mills and five bar mills. WWII brought huge expansion of EAF steelmaking (11 x 65/70t) to produce alloy steel for tank armour. Major modernization began in 1968 with addition of 4 x 200t EAFs, followed by a bloom caster. Today, just one upgraded 220t EAF produces 80% of the capacity of the original four furnaces.

1960 lineup: 1 small BF (0.266 Mtpa), 6 OH x 170/190t (0.560 Mtpa), 10 EAFs (0.485 Mtpa), 2 bloom mills/3 bar mills, 21 sheet mills

2022 lineup : 1 x 220t EAF, 110 MVA upgraded 1995 – 0.900 Mtpa, and 1 x 110t EAF, 20MVA 1951 [idle since 2020] – 0.300 Mtpa, 4-strand bloom caster (upgraded 1995) 0.860 Mtpa, 5-strand billet/bloom caster (2005) 0.680 Mtpa coupled with 8-stand Flex Cast-Roll mill for billets and square bars. 12” bar mill closed 2002 and primary mill probably closed about 2005.)

Currently still operating as the sole steelmaking, bloom & flex casting/billet mill facilities feeding the Republic bar mills at Lackawanna (13” mill operating) and Lorain (20” billet/bar mill & 9”/10” mill – idled since 2015)

Republic Steel Central Alloy District, Massillon Works, Massillon OH

Established BF 1926, OH 1915, mills 1915. BF closed 1965, OHs closed early 1960s – primary operations then obsolete. Billet mill and one bar mill continued operations until 2002. Massillon cold bar finishing continues in operation by Republic Steel.

Established 1915 by Central Steel Co., merged into Central Alloy Steel Corp. in 1926, and then into Republic Steel in 1930. Republic Steel in 1984 merged with Jones and Laughlin Steel to form LTV Steel.

Massillon 1960 lineup: 1 small BF (0.266 Mtpa), 9 OH x 115/225t (0.680 Mtpa), bloom/billet/2 bar mills, 9 rev. cold strip mills.

Massillon 2022 lineup: cold finished bar facilities 0.038 Mtpa, operated by Republic Steel.

Bethelehem Steel Bar Division, Lackawanna plant, Lackawanna NY

Established BF 1903, Bessemer 1903, OH 1904, mills 1903. Established 1903 by Lackawanna Steel Company, merged into Bethlehem Steel in 1922.

Integrated BF/BOF steel operations closed 1983. The Lackawanna 13” SBQ bar mill built in 1976 continued to be operated by Bethlehem Bar, Rod and Wire Division until 1993. In 1994 Veritas Capital Inc acquired the 13” mill for $13 million and operated it as part of Bar Technologies Inc. This was merged into Republic Engineered Steels in 1998.

Lackawanna 1960 lineup: 2 small & 5 medium BFs (3.8 Mtpa), 3 OH shops (total 35 furnaces 150/300t, 6.0 Mtpa), 3 bloom mills/billet/rail/heavy & medium structural/4 bar/79” hot strip mill/2 cold reduction/6 cold finishing mills.

Lackawanna 2022 lineup: 13” SBQ bar mill, 0.653 Mtpa, built 1976, recently upgraded with a 5-stand sizing mill, operated by Republic Steel.

U.S. Steel Lorain Works, Lorain OH

Established BF 1898, Bessemer 1895, OH 1909, mills 1895.

BF/BOF idled 2008 (but No.4 BF still in reserve), BOF replaced 2013 by EAF steelmaking, The new EAF and bar mills idled since 2015 but still in reserve.

Lorain plant history: Lorain plant was established 1895 by Johnson Steel and Rail Company as a Bessemer steel plant producing tram rails. BF ironmaking followed in 1898. In 1899 Lorain was acquired by Judge Gary’s Federal Steel Company, which was a foundation component in the creation of U. S. Steel Corporation in 1901. With the introduction of pipe mills in 1904, the plant was renamed National Tube Company. Open hearth steelmaking was introduced in 1909 and over the next four decades Lorain grew to become the world’s largest pipe producer. In 1949 Lorain installed USA’s last high capacity Bessemer steel shop, which was replaced in 1971 by BOF steelmaking, using much of the Bessemer shop infrastructure. In 1969/70 two high capacity 10” and 12” bar mills were added to produce automotive SBQ grades. Bloom casting and ladle steelmaking was added in the mid-1980s. In 1989, USX and Kobe Steel Company formed a 50/50 venture, USS/KOBE Steel Company, to acquire and operate Lorain works, excluding the pipe mills (which continued to be operated by USS). In 1995 a second caster was added to provide 100% continuous casting. A tank vacuum degasser was also added, possibly sometime during the 1990s (but I am still trying to pin down what year this was commissioned).

Lorain 1960 lineup: 3 small and 2 medium BFs (2.2 Mtpa), 12 OHs x 185t (1.8 Mtpa), 3 Bessemer x 30t (0.9 Mtpa), 46”/40” 2-stand bloom mill (1949), 30”/21” cont. billet mill (1949), 2 heavy mills for rounds for seamless tube feed, 2 skelp mills for welded tube feed.

Lorain 2022 lineup: all indefinitely idled in reserve. BF No. 4 (3500 tpd) idle since 2008 but still held in reserve with possibility for recommissioning if the market improves (2018 study investigated recommissioning the BF to market pig iron to flat product mini mills, but the project did not go ahead). A 150t EAF (1.2 Mtpa) built 2013 but idle since 2015. Ladle refining and tank vacuum degassing, 6-strand bloom caster (1.0 Mtpa, built 1983) and 5-strand bloom caster (1.2 Mtpa, built 1995), billet/heavy bar mill (1.2 Mtpa, built 1949), 12” SBQ bar mill (0.500 Mtpa, built 1970) and 9”/10” SBQ bar mill (0.420 Mtpa, built 1969, upgraded 1991). Grupo Simec said in its 2022 annual report that the 9”/10” mill is being prepared for recommissioning to produce cold-heading quality and SBQ bars as soon as market improves. The annual report also stated that the No.4 BF was written down to zero book value in 2015. But it is still held in idle status, with intention to recommission when the market improves. A coke inventory is still valued at $1.3 million.

LTV Bar Division and USS/Kobe post-integrated steel operations: in 1989, an ESOP called Republic Engineered Steels (RES) purchased LTV Steel’s bar division. In 1998 RES merged with Bar Technologies (then operating the residue of the former Bethlehem Steel Johnstown plant and the former Lackawanna bar mill) to form Republic Technologies International (RTI). In 1999 RTI acquired the integrated steel bar mill business of USS/KOBE Steel in Lorain, OH. RTI declared Chapter 11 bankruptcy in 2001 and was purchased in 2002 by Republic Engineered Products Holdings LLC (REP). The total acquisition cost was $410 million. REP chose not to acquire the idled meltshop and caster at Johnstown, but did acquire the Canton and Lorain meltshops and casters (0.9 and 1.5 Mtpa). The Lorain plant still operated BF/BOP route feeding a five-strand bloom caster and six-strand bloom caster. REP acquired the Canton billet mill, Lackawanna bar mill (0.588 Mtpa), only two of the three Lorain bar mills (0.432 Mtpa), but rejected the remaining Massillon and Chicago bar mills (0.9 Mtpa). RTI closed the Massillon bar mill, the Canton 12” bar mill and the Lorain 12” bar mill all in 2002.

REP acquired bar cold finishing facilities at Massillon (0.1 Mtpa) and Gary (0.08 Mtpa), rejecting another six bar cold finishing plants (0.1 Mtpa). In 2005 Republic Engineered Products Inc. was acquired by Mexican steelmaker Grupo Simec Guadalajara. In 2011 the name of the US bar subsidiary was changed to Republic Steel (turning the clock back almost four decades).

In 2013 Republic Steel commissioned a 150t EAF (1.0 Mtpa) at Lorain, but this and the rest of the Lorain plant was idled in 1915 and has not been operated since. It is however still held in reserve for when the market justifies recommissioning.

Related background, no longer involving Republic Steel.

Bethlehem Steel, Cambria Works, Johnstown PA

Established BF 1853, Bessemer 1871, OH 1879, mills 1853.

Established 1852 by Cambria Iron Co. reorganised 1862 as Cambria Steel Co. By 1880 it was the largest steel plant in the USA. Merged into Midvale Steel and Ordinance Co. in 1916, then acquired by Bethlehem Steel in 1923. There was a burst of new and modernised mill investments from 1924 to 1926, then over the next half century Johnstown plant received only sporadic modernisation investments and limited expansion compared to other Bethlehem integrated mills. By the 1960s Johnstown was faced with outmoded technology, vulnerable bar and rod product range, and poor location for both raw materials and market access. Bethlehem Steel’s strategic planning response showed surprising lack of direction. In 1969 construction began on a continuous caster, but after millions had been invested in site work and foundations, the project was cancelled. In 1973 a project was announced to build an EAF shop to replace the obsolete BFs and OHs, reducing steel capacity from 2.3 to 1.0 Mtpa. By 1974 this was cancelled. In 1975 work began on a BOF shop, requiring continued operation of the BFs. Completion was targeted for 1978, but in 1977 a major flood once again seriously damaged the Johnstown plant. The BOF project was abandoned and a new plan to install EAFs was adopted, this time reducing capacity from 1.8 to 1.2 Mtpa. Once again, the new steel shop would have no continuous casting!

Johnstown 1960 lineup: 4 small & 2 medium BFs (2.0 Mtpa), 20 OH x 170t (2.4 Mtpa), bloom/2 billet/9 bar/rod/wire/2 plate mills

Johnstown 2022 lineup: two or three of the original Gautier plant mills (9” and 14” bar mills both built 1926) are still operated by Gautier Steel. The 12” mill (built 1893) might have been closed. The original Johnstown wire mill is now operated by Liberty Wire Johnstown.

Johnstown post-integrated steel operations: Closed BF/OH 1981, replaced by 2 x 185t EAFs, which Bethlehem continued to operate (without continuous casting) until 1992. The EAFs and remaining mills were then closed and offered for sale. Veritas Capital Inc. purchased the Johnstown plant in late-1994 for $25 million, planning to operate the EAF shop and add a caster, to produce 0.7 Mtpa of billets to feed the Lackawanna 13” bar mill, also purchased for $13 milllion by Veritas Capital. BRW Steel Corp. was set up by Veritas to be the operating company, but the name was later changed to Bar Technologies Inc. Limited production at Johnstown resumed in 1996 and a caster was commissioned in late 1996 or early 1997, but the operation suffered heavy losses. The Johnstown primary plant and Lackawanna bar mill were merged by Veritas and associated Blackstone Group into Republic Technologies International in 1999. The Johnstown plant was permanently closed incurring a $55 million write off in 1999/2000.

The three remaining Johnstown Gautier plant specialty bar mills (14”, 12” and 9”) were acquired by J-Pitt Steel Inc. in 1993. J-Pitt filed for bankruptcy in 1997 and ownership changed to Gautier Steel Ltd. in 1998. The three bar mills are still operated by Gautier today. In 2015, associated firm Gautier Specialty Metals added a 58” 4-high plate mill for alloy, tool, stainless steels and titanium armour plate. This plate mill was re-engineered from a decommissioned plate mill from Gadsden AL., with the future option of widening to 110” width. The Gautier bar and plate mills are operated in the original Gautier plant mill buildings constructed in 1892. The three bar mills were originally built in 1893, 1926 and 1926, so are now 96 to 129 years old.

The Johnstown wire mill was acquired in 1992 by Johnstown Wire Technologies, which in turn was acquired in 2019 by the Sanjeev Gupta’s international Liberty Steel Group, renaming it Liberty Wire Johnstown.

[Some comments speculate that Grupo Simec bought it to shut it down to remove competition.]

|

| William Jones posted Lorain, Ohio Steel Plant, 5 Blast Furnaces from top of the B.O.P., believe possibly circa 1981. Furnaces are numbered from east to west or right to left in this picture and in order of first built. From right to left: #1, #5, #2, #3, and #4. Furnace #5 was the last built and in the size and style of #1 & #2 to fit between them and fulfill orders as demand warranted. |

|

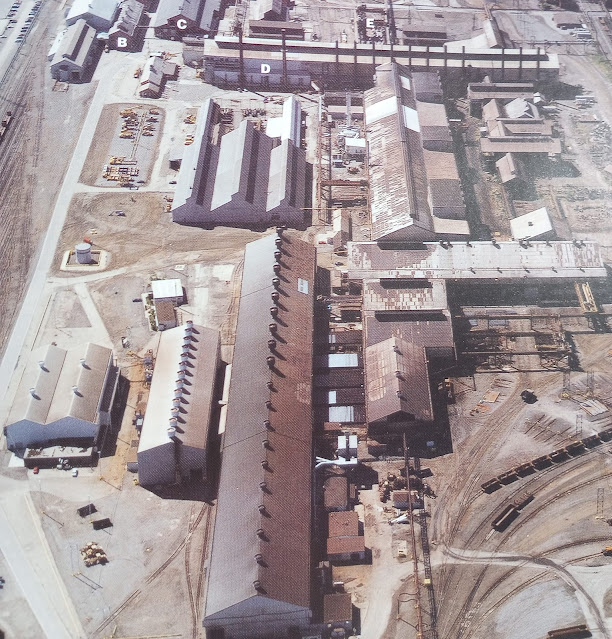

| One of four photos posted by Clarence Rutherford US Steel Lorain Ohio Matt Keckler: Pipe mill Clarence Rutherford: Matt Keckler yep at one time is was National Tube my grandfather worked there my dad worked the railroad in the plant and I worked the railroad in the plant also. Doug Majka: In the sky view pic I see blast furnaces, coke plant, open hearth furnaces, rolling mill, and pipe mills at the top. |

|

| Doug Majka posted Lorain national tube - 1936 aerials ., limestone & ore piles in foreground, blast furnaces in center, open-hearth steel plant at upper right, tube mill in rear, coke ovens between tube mill and blast furnaces. |

|

| Doug commented on his post The Bessemers are also in that picture. |

|

| 1960 Lorain Quads and 1953 Avon @ 24,000 |

|

| 1903 Oberlin Quad @ 62,500 |

|

| Raymond Boothe posted USS Lorain (Ohio) Works: View of blast furnaces 6 & 7 (unkn/Dr. Raymond Boothe collection). |

Andrew Shafer Taconite would come from the Reynolds Indiana Magnetation plant via CSX.

David Jordan This was announced last year some months after ERP Iron Ore PLC bought Magnetation's assets. Good news for CSX, and probably TP&W (bentonite for the plant shipped from Wyoming was routed BNSF-Peoria-TPW to a transload operation at the Co-Alliance elevator on Reynold's west side). May be the Indiana Rail Road Co will resume limestone shipments as well?

Andrew Shafer It's good news for the concentrate shipments too of course. That was a train a day each way.

Republic Steel to Restart Lorain, Ohio, Manufacturing Plant

Lucas Irons shared a report of restarting in 2Q 2019

David Jordan ERP Iron Ore's Reynolds, Indiana plant definitely won't be supplying ore pellets to Lorain.

https://mexico-now.com/.../5010-mexican-steelmaker-ahmsa...

At least the first two of three videos are of Republic

David Jordan This was announced last year some months after ERP Iron Ore PLC bought Magnetation's assets. Good news for CSX, and probably TP&W (bentonite for the plant shipped from Wyoming was routed BNSF-Peoria-TPW to a transload operation at the Co-Alliance elevator on Reynold's west side). May be the Indiana Rail Road Co will resume limestone shipments as well?

Andrew Shafer It's good news for the concentrate shipments too of course. That was a train a day each way.

Republic Steel to Restart Lorain, Ohio, Manufacturing Plant

Lucas Irons shared a report of restarting in 2Q 2019

David Jordan ERP Iron Ore's Reynolds, Indiana plant definitely won't be supplying ore pellets to Lorain.

https://mexico-now.com/.../5010-mexican-steelmaker-ahmsa...

At least the first two of three videos are of Republic

Rob Van Wagnen: That place has been a ghost town for 20 years

So did Johnson Steel become part of Republic or USS?

|

| Howard Williams posted Original Bessemer Power House Johnson Steel Co. Lorain, Ohio1895 |

|

| One of 23 photos posted by Jim Huber Circa 1920's. [It looks like they had two Huletts.] |

|

| One of 23 photos posted by Jim Huber Lorain steel docks Circa 1898. |

|

| David Biggs posted This is from the mid1970’s,Raw Materials Department ore docks, Lorain Works |

|

| Bob Adams posted U.S. Steel , Lorain 1953 . Anything look familiar ? Tony Kocan: The slag piles. Especially at night. You could see them glow from the 21st street bridge. Dennis Friess: 5 Blast Furnaces. There were only two left at the end. Vicki Cowie: Dennis Friess actually during that power out number 3 furnace was destroyed. Then after that number 4 was shut down. Worked there 17 years. Was there when the electric furnace was built. I was the only woman that operated it. Ken Washio: The pollution. I remember a trip long ago to Cleveland where I ended up on the observation deck. I'll never forget the brochure that '... to the west you can see the smoke rising from the giant steel mill in Lorain.' Sure enough, there it was... a dome of polluted air indicating Lorain. Felt sorry for those who lived close to the mill. However, those mill jobs were the financial background of thousands and thousands of families over the years. Linda Macartney: Thank you for sharing. That's a great picture of their docks on the Black River. Lake freighters, 24/7, were so integral to the entire operations of the facility. Malcolm B. Thompson shared Ryan Mihalak: How far is the Lorain shipyard from here? James Torgeson shared U.S. Steel , Lorain 1953 . Anything look familiar ? Don Stransky: Worked at the docks in the 70’s , the newest bridge crane was built in 1960. James Torgeson: Last Huletts built, also in 1960. |

|

| Comments on Malcom's share |

|

| Howard Williams posted New Blowing Engines @ Lorain Works US Steel 1901 Notice the operator in suit & tie on floor by High pressure steam cylinder. I worked there as a supervisor in the 1960’s when they last ran. The original power source was 150 psi steam, but they were converted to 250 psi in 1922 when a new boiler house was built. [There are also some comments about using gas from the blast furnaces to generate 25hz electrical power.] |

|

| Ian Warner shared a post by Bob Adams U.S. Steel , Lorain Pearl Gates 1902 . |

Bubba Dubs posted two photos with the comment: "Republic Lorain."

[Some comments mention that Canton is rolling trial billets for Lorain to restart its bar mill.]

|

| 1 |

|

| 2 |

|

| Comments on Bubba's post |

|

| Bubba Dubs posted Lorain Ohio. Blast furnaces 4 and 3 (left to right) Doug Majka: #3 on the right had a catastrophic meltdown in 2003 when we had the 3 day power outage. No power to run the cooling water pumps, and lack of maintenance on the mills generator, so they couldn't make their own power. Doug Majka: I think it was 2008 when they idled #4. John Groves  Lorain blast furnaces Nos. 1 & 2 commissioned 1899. No.3 1904 No.4 1905 No.5 1907 Nos. 3 and 4 completely rebuilt with 26' hearth diameters in 1941 and 1942. |

|

| Doug Majka commented on Bubba's post |

Jason Warner contributed two photos as comments on Bubba's post:

|

| 1 |

|

| 2, cropped |

|

| Bubba Dubs posted At the top of the photo sit bottle (Torpedo/Submarine) abandoned near the blast furnaces they served in Lorain Ohio. These were used to transport molten iron to the basic oxygen furnace to be refined into steel. Ray Schloss shared Richard Allison: Well, at least they were turned down not to trap rainwater. I would say they are frozen from corrosion, everything from the trucks under the ladles to the trunnions. I am surprised they weren't scrapped by now. AJ Riley: Susan Cz it’s republic, it used to be US steel then Kobe bought them and divided the mill. The US steel side only makes pipe, the Republic side takes scrap and makes steel bars basically |

|

| Facebook comments on Buba's post |

|

| Facebook comments on Buba's post |

Dennis Szabo posted three photos with the comment: "EAF Repubulic steel Lorain Ohio looking down from the charge crane 2014."

Michael Bolinger: How many tons y’all get out of a heat?

Dennis Szabo: 150 ton 150 tons to lite are ladles and casters were set up for 300 tons we fed the billet caster but couldn’t keep up with the bloom caster

Richard Allison posted four photos with the comment:

Lance Aerial Media posted four photos with the comment: "Steel Mill in Lorain, Ohio."

John Boles posted seven photos with the comment: "BOP N Vessel trunnion repair. June 2nd, 1980. #lorainworks."

|

| 1 |

|

| 2 |

|

| 3 |

|

| Michael Watchorn posted 40" mill lorain |

Richard Allison posted four photos with the comment:

I know people wonder about the two blast furnaces (No.3 and No.4) standing at Republic at Lorain, Ohio but they used to belong to USS-Lorain Works. I don't know where I got these photos but I have them.One of these furnaces was severely damaged and I think there was a problem where they lost power to one of the furnaces. I remember one of them was not feasible to repair. Maybe someone here has more details than what I have.These photos were taken in 2016. I know a few years ago there was a plan to open one of the furnaces to make pig iron but the venture never got off the ground. Looking at the photos, I can see corrosion and what time does to equipment. It is obvious these furnaces have been down too long to be revived and the cost would be prohibitive to replace and update equipment on these furnaces. All the electrical would have to be redone and all the piping is probably useless after all this time.The last time I was on these furnaces, they were running back in 1977 or 1978. They were in pretty good shape back then.Look for yourself.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Jim Votruba posted Six strand billet caster Lorain, Ohio. Matthew Peters: I spent about 10 years in that caster. We ran mostly 6" and 10" rounds and squares. Jeffery Fetty: We barely keep three strands going at Steel of West Virginia. Do you cut with automatic torches if so what do you do if one in the middle misses a cut? Matthew Peters: The torch pulpit operator would rush out there and make an e-cut with a 12' torch. If they were running too fast, they would call maintenance and I would make the cut for them. 6" rounds were the worst because they would come out looking like snakes and lie outside of the automatic torch's reach. Multiple strand failures were the worst. Jeff Bindas: Wow…..six strands! Wow…….rounds! Wow………imagine caster size, heat size, furnace size, ladle size, tundish size Daniel Oxender: Uss? Jim Votruba: Daniel Oxender Republic Jim Votruba posted again I posted this picture a few days ago. I'm re-posting because I can't believe that nobody noticed that the 4 strands on the left are rounds and the 2 on the right are squares. We were in the process of qualifying the new EAF and wanted to run 6 inch rounds. Due to maintenance issues, there were only 4 round molds available. We were going to run a "vanilla" grade that we actually cast in both rounds and squares. In an effort to be able to cast the entire heat, I thought it would be a good experiment to try to run 6 inch squares at the same time. It actually turned out great. We, naturally, had to use two different speed charts and finagle some smooth moves in the torch cut, run out and cooling bed but we cast the entire heat. We never would have been able to do that with only 4 strands. As I said, we were qualifying the furnace so everything was scrap anyway. Just proves that if you have good people willing to try new stuff you can get it done. I was fortunate enough to have what I considered the best in the business working with me on that caster. Jim Votruba: Brian Stevens yes Cliff Martin: We used to run 13.5” on 2 strands and 20.125” on 2 strands. Actually worked great! Roger Dean posted Spray chamber of the billet caster at Republic Steel Lorain, Ohio. Taken probably around 2011 , was shut down in 2015. |

|

| Jim Votruba commented on Roger's post |

I'm glad there are three workers in the scene to give us a sense of the scale.

|

| Douglas Freeman posted 1983 photo of the ladle turret at the 6 strand rounds caster at US Steel Lorain Works. Danny Floyd: 350 ton Ladle? Douglas Freeman: Danny Floyd 300 ton, (220 tons of steel) Jammer Mantini: Worked on that cast floor many years. Such a shame what Jaime Vigil and his people did to that mill. Douglas Freeman: Jammer Mantini that is me in the green jacket standing at the base of the turret! I was GF of maintenance, 1983 - 1985. |

|

| Bubba Dubs commented on Jim's first post Where would this be in this pic Jim Votruba? |

|

| 3D Satellite |

|

| Jammer Mantini posted Never thought I'd see the day when this mill would go idle. [Jammer finally revealed the location as Lorain after someone guessed Birmingham. And he commented "This mills range was 10.25" up to 26". Was one of a kind." in another reply. Some one else's comment indicated it was USS Lorain in response to a third location question. (The second one was ignored.)] Joseph Sapienza  US Steel National Tube in McKeesport PA made the best seamless pipe for over 100 years. You can now ride your bike on the trail that runs across the property. https://picryl.com/.../us-steel-national-tube-works-main... Birmingham Bob: Alan Belancik They had two mills - #1 seamless went from 3 1/2 to 7" I believe and #2 seamless went from 8 5/8 to 16" without the rotary mill and with the rotary Mill it went to 24" - It closed in 1986 --- 35 years ago Wow!! Pete Maxfield: I worked at USS Geneva works pipemill, it has all been pulled down and is a Fed Ex warehouse. |

|

| David Koehrsen posted Republic Lorain Oh, around 2014. It is north teeming. |

|

| 1 of 8 photos posted by Abandoned The industrial landscape of Lorain, Ohio is characterized by the presence of a colossal steel mill. Historically, the facility, known as Lorain Works, has been owned by various entities, including U.S. Steel's subsidiary National Tube and Republic Steel. The plant's infrastructure includes five blast furnaces, a coke plant, and an array of mills for refining steel into blooms, bars, and billets. The production output of the mill has fluctuated over the years in response to changes in demand for its products, with a heavy dependence on the automotive and energy industries. The steelmaking industry in Lorain has been impacted by a range of factors, including fluctuations in the gas and oil sectors, the use of alternative materials in the automotive industry, such as those that are lighter, more malleable, and resistant to corrosion, and increased competition from imported steel. In 2015, steelmaking operations at the mill came to a halt, and its shaping and treating lines have been inactive since 2020. Despite ongoing discussions regarding the possibility of restarting operations at the facility, no concrete plans have been implemented to date. ➤ Check out more on the history of Lorain Works at Abandoned shared |

|

| John Boles posted The sun will come out, tomorrow. |

|

| Jenn Marie commented on John's post |

|

| William Jones posted View of the docks at US Steel's Lorain Works, circa 1975. Great Lakes freighter Leon Fraser visible in background. Dan Sciulli: I remember going on board and the captain would take us to the galley and eat steaks, if we would get him unloaded fast. The good old days. |

William Jones posted twelve photos with the comment: "The Lorain, Ohio Steel Mill started out as Johnson's Rail Mill in 1894. Later National Tube, U S Steel, USS/KOBE, Republic and so on till what it is today. Here are raw pictures from the start of its construction I'd like to share with you."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| 11 |

|

| 12 |

|

| Nancy Guest Tolliver posted US Steel Lorain blooming mill 1952 |

|

| Graham Whitfield commented on Nancy's post Soaking Pits and Slabbing Mill wonderful era. |

|

| One of five photos posted by Kevin Tomasic |

|

| Jammer Mantini posted, cropped Republic Steel Lorain #4 Blast Furnace. Formally owned by US Steel. Really surprised they haven't used one of their furnaces for pig iron. They been down a while probably cost a fortune but pig Iron is big business nowadays. |

|

| Jason Warner commented on Jammer's post, cropped I’ve been there before. |

Lance Aerial Media posted four photos with the comment: "Steel Mill in Lorain, Ohio."

Dennis DeBruler shared

Michael Maitland: Great photos. What is the current status of this plant. Believe this hot end is gone for good, but pipe mills in the distant still running.

Alex Georgas: Michael Maitland no, nothing is running in Lorain. Pipe mills were shout down in 2020 by USS.

Brian Olson: You have to wonder why they couldn't operate the EAF, caster and bar mill profitably. I understand why the ore based steel production had to go but they have a brand new eaf, modern caster and 1970s bar mill.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

Brian Holzhiemer posted ten photos with the comment: "Lorain steel yard!"

Jacqueline Thomas: I saw where 1000 jobs coming back to republic steel, a video was posted about it.

Steve Rowan shared

I don't know when or where this was.

Jim Rickard posted four photos with the comment: "USS/KOBE Lorain Ohio."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

John Boles posted seven photos with the comment: "BOP N Vessel trunnion repair. June 2nd, 1980. #lorainworks."

Mike Maddog Madigan: In Weirton a long time ago, when the Harness safety was instituted. the vessel was down, we all had belted up. Had to walk the drive shafts to do some jobs, the shaft were 6 foot from the ground and the harnesses had 9 foot tethers.. Well Safety was called, and dont ya kno good sense went in the dumper, we were not permitted to undo the tethers.. The joys of OSHA, and Common Sense in the dumper..

Larry Ridenour: We rebuilt one in the early 80s at McLouth Steel in Trenton Michigan, remember welding all those teeth on the bull gear. Hot job as they kept heat on the gear almost constantly.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| Bubba Dubs posted Lorain Ohio, 2021 [According to some comments, the blast furnace can never run again because it wasn't shut down properly.] |

|

| Bradley A. Lacko posted Arial view of Republic Steel - Lorain Bottom right corner is where the blooms were staged Bob Diamond: old soaking pit building running top to bottom, with the stacks. Blooming mill running to the right, attached to soaking pit building. The single stack shadow on the middle right is from the cast bloom reheat furnace. |

|

| Bradley A. Lacko commented on his post |

|

| Bradley A. Lacko commented on his post |

|

| Phil Jadlowiec posted |

Clarence Rutherford: There were narrow guage tracks that were used to moved the ingots into the soaking pit building

The cars were called pricker cars the molds were picked up by a crane off of the standard guage rail cars

The mold was then sat down on top of the pricker cars forcing the ingots up out of the mold a few feet so the crane inside the soaking pit building could pick up the ingots and place them in the soaking pits

Dennis Szabo: Richard Allison bar mill is up and running again.

19 photos "They are currently [Oct 13, 2021] restarting the 9/10” bar mill."

Jul 1, 2024: 0:58 drone video of a shuttered mill

%20Steel%20Mill%20Pictorial%20_%20Facebook.png)

I spent 41 years in the pipe mills....quite familiar with it...shoot me question if you like

ReplyDelete