Braddock Works: (Satellite, two blast furnaces have been preserved as a national historic landmark)

(Whoops, I also wrote about the Edgar Thomson Works in my other blog. Any content in these notes that was specific to Edgar Thomson has been moved to those notes.)

|

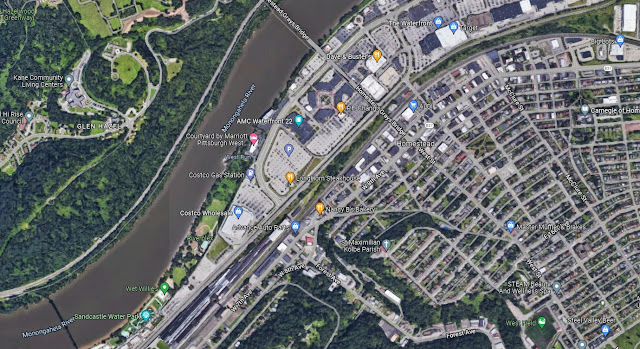

| Andrew Stewart shared a Jackson-Township historical preservation post [This is the second of 88 photos. The steel mill photos are intermingled with images of the town and its people.] Aerial view of the former U.S. Steel Corp. Homestead Works in Homestead Borough, Allegheny County, just outside of Pittsburgh in the 1950's. This area is now known as "The Waterfront" shopping, dining and entertainment complex. (Photo from http://explorepahistory.com/) Jackson-Township historical preservation posted again with the same comment. Phil Jad shared |

|

| JaQuay Edward Carter posted AERIAL VIEW OF HOMESTEAD WORKS 📸 William J. Gaughan c. 1950 Focusing on the area around Open Hearth #4, which was located on E. Eighth Avenue at City Farm Lane, nearby the legendary "Hole In The Wall" - an unofficial side entrance to the mill site before reaching the Pennsylvania "Pennsy" Railroad. The Main Gate of Homestead Works, also known as Carnegie-Illinois Steel Company, was to the right O.H. #4, across from Harrison and Grant streets in Munhall. Ravine Street is just beyond on the top right of the image. St. Michael Slovakian R.C. Church was known as the "Steelworkers Parish," because of its close proximity to the Homestead Works, and many original members worked in these steel mills. |

|

| James Bost posted THIS GROUP OF POSTCARDS ARE OF 4 OF OUR LOCAL MILLS.USS ET BRADDOCK,CARRIE FURNACE RANKIN,USS HOMESTEAD WORKS & MESTA MACHINE HOMESTEAD.FROM ORIGINAL PAINTINGS OF HOWARD FOGG,LATE 1950s |

|

| Bob Ciminel posted Homestead Works, 1950. |

|

| 1 of 18 photos posted by Anthony Cominotti Homestead Works and Carrie Furnaces |

|

| Josephine Lily Brown posted 1950 USS Homestead Works. |

|

| safe_image for Photo |

|

| Steel Valley History posted A familiar site growing up in the Steel Valley. Kenny Hall shared Will Jamison: Homestead. Painted on the roof of the building next to the highway is "UNITED STATES STEEL CORPORATION". That eliminates other companies. Below that are oil storage tanks and the high line leading into the open hearth. Both signature items in photos of the open hearth taken from the highway sidewalk. |

|

| 1 |

|

| 2 |

|

| safe_image for These 10 Rare Photos Show Pittsburgh's Steel History Like Never Before |

|

| David Mancak posted OH5 |

|

| Ted W. Makropoulos posted MUNHALL JUNCTION, c. 1910 Passing the Homestead Works, also known as the Carnegie-Illinois Steel Company, which was actually located in Munhall (formerly East Homestead). Its nickname was "Carnegietown." The Carrie Blast Furnaces (in the distance) were situated across the Monongahela River, and connected to Homestead Works via the Hot Metal Bridge (1 of only 7 built in the world). The bridge spans between Whitaker Way and Ravine Street, in order for vehicular traffic to cross a hollow created by the Whitaker Creek. This was a very precarious crossing for many decades, leading to a dangerous intersection at Ravine Street, where one must quickly veer to the right to proceed straight onto E. 8th Ave. 📸 Library of Congress (Colorized) Edwin Moore: The Monogahala River was lined for more than 20 miles with Steel Mills with Steel mills including The US Steel Homestead Works, and then they mostly shut down between 1980 and 2000. Rick Rowlands: The buildings in the foreground are for the 48" universal plate mill. |

%20Steel%20Mill%20Pictorial%20_%20MUNHALL%20JUNCTION,%20c%20_%20Facebook.png) |

| Comments on Ted's post |

|

| Roy Scott posted Pittsburgh---Homestead Works in 1908. The steel for the Empire State Building in NYC came from Homestead...The CorTen Steel for the US Steel Building in Pittsburgh came from Homestead. Anthony Zacchero: That was when it was Carnegie Illinois Steel Company. The forerunner of United States Steel Corporation aka USS then USX for a while now back to USS. |

|

| Phil Jadlowiec posted Homestead, Pennsylvania, circa 1910: Homestead Steel Works, Carnegie Steel Co. Mike Price: That is OH4 in Munhall. 𝗥𝗲𝗺𝗲𝗺𝗯𝗲𝗿 𝗪𝗵𝗲𝗻: 𝗣𝗲𝗻𝗻𝘀𝘆𝗹𝘃𝗮𝗻𝗶𝗮 posted Homestead, Pennsylvania, circa 1910 Homestead Steel Works, Carnegie Steel Co. [Some comments point out there was not Carnegie Steel in 1910 because it became part of US Steel in 1901.] 𝗥𝗲𝗺𝗲𝗺𝗯𝗲𝗿 𝗪𝗵𝗲𝗻: 𝗣𝗲𝗻𝗻𝘀𝘆𝗹𝘃𝗮𝗻𝗶𝗮 posted Homestead Works • Pittsburgh, Pennsylvania• 1910! |

|

| Jackson-Township historical preservation posted Smokestacks at the Carnegie Steel Works in Homestead, Allegheny County in 1907. David Mancak shared |

|

| Blaine Stanziana posted Homestead works 1982 I believe Mike Barry: That's the South end of OH 5 The stacks are from the open heath ovens. the building to the right of the stacks is the charging floor. To the left out of view would be Pitside where I worked in 1981. The building on the far right is the General Office Building where the Superintendent and his staff worked. Joe, they [today's extant stacks] were behind the camera position on the other side of the bridge. |

|

| Duwi Czarnecki posted Homestead Slab and Plate stacks. All that's left of Homestead Works thanks to the EPA. Don Mc Carthy: its a post from an Indonesian spammer trying to rage bait people |

|

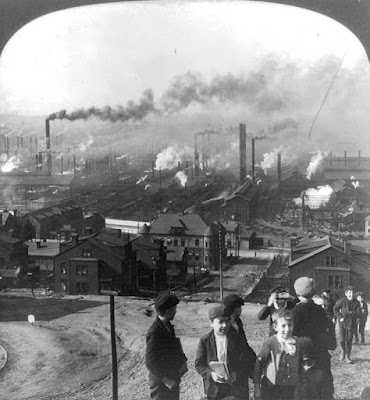

| Jackson-Township historical preservation posted Children walking up a hill above the steel mills in Homestead, Allegheny County in 1907. Rob Greene: Cow’s hill! This is the dead end of East 10th. David Mancak shared looks to be the Eastern end of the US Steel Homestead works in Munhall Pa. David Mancak shared again |

|

| Jackson-Township historical preservation posted Entrance to the Carnegie Steel Works, the largest steel mill in the world, located in Homestead, Allegheny County in 1913. David Mancak shared Richard Ryaby: That’s the gate I went in 1973 to go to work in no. 2 Structural mill. |

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Remember When: Pennsylvania posted Homestead, Pennsylvania, circa 1910. "Homestead Steel Works, Carnegie Steel Co." #rememberwhenPA 📷: DPC Shea Cahill: scene of some one of the American labor movement most violent encounters. Carol Snyder: My family almost bought one of those company houses in 1955. My dad was the editor of The Homestead Daily Messenger. |

|

| Blaine Stanziana posted Homestead Works |

|

| 1 |

|

| 2 |

|

| Blaine Stanziana posted Homestead works 1950 |

|

| Chuck Half posted I worked at OH5 for 3 months in '67 in Quality Control documenting analog instrument readings and tossing AL shot into molds during tapping....History Question - What would Swindell Dressler have "constructed" as part of the Defense Plant OH5 complex? My Dad leased part of his Homestead furniture warehouse to them. The USS plant picture in 1942(???) appears to be prior to operations. Do you agree? MaryAnn Eric VanHorn: That's pretty cool! Where was the warehouse located?. Chuck Half: MaryAnn Eric VanHorn 7th Avenue Mark Kasprzak: They might have rented the space as a staging area for their equipment before an outage installation. ?? Joe Chiodo: Look at the smoke stacks of OH5, it looks like that part is working. |

|

| Bob Ciminel posted Homestead Works by John Pennell, date unknown but probably early 1900s. [The early 1900s is rather late for the artist to think that smoke was a sign of prosperity. Chicago was actively trying to reduce the amount of smoke in the city by 1915. On the other hand, the amount of smoke may be accurate and that shows why they were trying to reduce the smoke produced by railroads by trying to force them to switch from steam to electricity. The IC did electrify their passenger service. But diesel locomotives saved the railroads from the pressure to electrify.] |

|

| David Mancak posted Munhall end of the Homestead works formerly before it was torn down. |

Matt Nelson: 1892 - Homestead Works workers strike leading to the Battle of Homestead on July 6, 1892. At least three Pinkerton guards and seven workers were killed in the battle.History of the Homestead Works.1770 - First settlers arrive1872 - Homestead Bank & Insurance Co. lays out and names the town.1873 - Pittsburgh, Virginia & Charleston Railroad (PRR) arrives and first lumber mill opened.1879 - Pittsburgh Bessemer Steel Co. builds two converters and a blooming mill.1880 - Homestead incorporated as a city. (pop. 7,000)1883 - Carnegie Phipps Co. buys Pittsburgh Bessemer.1884 - Carrie Blast Furnaces built.1886 - First open hearth built1898 - Carnegie buys Carrie Furnaces from the Fownes Brothers.1899 - Slabbing mill, universal and sheared plate mill built.1900 - Howard Axle Works organized.1901 - Carnegie Steel Company merged with U.S. Steel Co.1903 - Schoen Steel Wheel Company organized in McKees Rocks.1908 - Carnegie Steel buys Schoen Steel Wheel.1935 - Carnegie Steel Co. merges with Illinois Steel Corp.1942 - Schoen Steel Wheel and Howard Axle merged.1951 - Carnegie-Illinois merged with U.S. Steel.1956 - Saxonburg sintering plant built.1967 - Saxonburg becomes a division of Homestead Works.

|

| 1 |

|

| 2 |

|

| 1 Homestead Works - this half (essentially) was added 1942. Inset: “The Ward” area contained the 6,000 squalid, dirty houses of steelworkers. Many immigrants. |

|

| 2 Homestead Works - this half was existing, 1942. |

|

| Bob Ciminel posted |

|

| JaQuay Edward Carter posted UNITED STATES STEEL MAP, c. 1978✨️ Fanning Out From #HomesteadWorks 📍 Other related iron & steel facilities, included: •Carrie Blast Furnaces in Rankin •Edgar Thomsom Works at Braddock •Duquesne Plant in Duquesne •McKeesport National Plant at McKeesport •Irvin Works at West Mifflin •Christy Park Works in McKeesport •Clairton Works at Clairton •U.S. Steel Research Facility in Monroeville •Wheel & Axle at McKees Rocks •Saxonburg Sintering Plant in Butler County Jf Hull: We still Mon Valley Works Strong.... Clairton, Edgar Thompson and Irvin... even though the writing is on the wall |

|

| William David posted Homestead works |

|

| Andrew Stewart shared a Jackson-Township historical preservation post Antique Map of the town of Homestead, Allegheny County in 1902. (Photo from Nancy Ballog Wall via https://www.facebook.com/groups/263672046993077/ )Library of congress Panoramic Maps You can zoom in and see the detail. https://www.loc.gov/item/75694988/ |

|

| JaQuay Edward Carter posted HOMESTEAD MAP, 1902 T.M. Fowler & James B. Moyer Focusing on the industry flanking both sides of the Monongahela River. On the right was the Homestead Steel Works (9) and on the left was Carrie Blast Furnaces, a "pig iron" production facility. The pure and refined "pig iron" was then added to other scrap metals at Homestead and formed into steel in the open hearths and rolling mills. The Homestead Steel Works were first constructed in 1881. Andrew Carnegie bought the 2 year old Homestead Steel Works in 1883, and integrated it into his Carnegie Steel Company. It was once the largest steel mill in the world and the most productive of the Mon Valley's many mills. There were three bridges spanning the Monongahela River in this view, including: (from bottom to top) 1. Pittsburgh & Lake Erie Railroad Bridge at Munhall (also known as the Pinkerton's Landing Bridge or P. McK. & Y. "Pemickey" Bridge). 2. Hot Metal Bridge, connecting Homestead Works with Carrie Furnaces. It was built around 1900, 5x stronger than a normal bridge, with fireproof brick and 2-inch steel plating along the sides. There were only 7 built in the world, with 2 in Pittsburgh remaining. The other connected Jones and Laughlin Steel Company's iron (Hazelwood) and steel (Southside) facilities. 3. The 1897 West Braddock Bridge, a narrow trolley bridge equipped with a wooden deck. It was later rebuilt and renamed, Rankin Bridge. (M) was the site of Munhall Methodist Episcopal Church on Ravine Street. The building was later home to a school. |

|

| Kenny Hall posted Postcard of the Carnegie steel Works in Homestead Pa. |

|

| Frank Kish posted Post card i have for Homestead pa ,Shopping center now . But us steel does have its research center at north end of strip malls one building remaining used by Bristel metals all other buildings are gone! [He also included the back side, which as the text: ""View of Homestead United States Steel Works --- one of the world's largest and oldest steel production mills in the world. A comment says US Steel has its research center "at the far north end."] |

|

| Frank Kish posted Text on the back: "HOMESTEAD, PA. View of the Homestead United States Steel Works -- one of the world's largest and oldest steel production mills in the world. Color by Goll Studio" Scott Layman: Wow such a great picture….the bridge still stands |

|

| Jerry Billak posted Homestead works United States steel |

|

| Michael Maitland posted There was some discussion of the Homestead plant. A few years back visited the Rivers of Steel museum in the strip district. They had this wonderful model and storyboard explaining every building. If I remember correctly, they had a major expansion in WW2. Great visit, recommended. |

|

| Bob Ciminel provided via James Torgeson post Homestead Works, looking toward Mesta. |

|

| Mike Theisler commented on James' post |

|

| Robby Beck posted 397 passing US Steel Homestead works |

|

| Jane Cheuvront posted Carnegie Steel Blast Furnace. In 1902 was sold to U.S. Steel. [A comment indicated that the price was $500m ($17b in 2021 dollars). ] |

|

| Jackson-Township historical preservation posted Four steel workers in Homestead, Allegheny County pose for a publicity photo for their choir in 1954. (Photo from William J. Gaughan via https://www.facebook.com/OddPittsburgh/) [And it catches a couple of the blast furnaces.] Phil Jad shared |

Photograph 1: Homestead works panorama from 1912 Homestead booklet.Photograph 2: aerial view of Homestead works with Carrie furnaces in the background (University of Pittsburgh, collection of William J. Gaughan).I never got the chance to visit this famous historic steel mill. So instead I researched and wrote a detailed profile of the plant facilities.HOMESTEAD STEEL WORKS – Facility HistoryThis is a brief technical history of all the furnaces and mills operated at the famous but not very well documented Homestead works. There has been far more written about the infamous 1892 strike than the rest of Homestead’s impressive 105-year history.The Homestead Steel Works were established in 1879-81 by a group of Pittsburgh steel plant owners, including resentful former Carnegie partner Andrew Kloman. They formed the Pittsburgh Bessemer Steel Company as a Bessemer-based rail mill to compete directly with Carnegie’s nearby Edgar Thomson rail mill. A secondary purpose was to supply billets to their individual finishing plants. To meet booming rail markets, Carnegie had ceased supplying billets from Edgar Thomson to these local mills.Andrew Kloman died in 1880 a few months before the Homestead plant was completed. This was a significant blow to the venture to lose Kloman's mechanical and technological leadership. He was replaced as manager by William Clark, who was outspokenly anti-union.Homestead began steel ingot and rail production in 1881 but faced protracted strikes and mounting problems competing with Carnegie's aggressive style of business. In 1883 Carnegie purchased the Homestead works at not much more than the cost of building the plant, plus a reasonable allowance for the increased land values.Carnegie immediately began integrating Homestead into his steel operations. Over the next 18 years he turned Homestead into America’s preeminent producer of open hearth steel as well as structural and plate products, including heavy armour plate. He built three open heath shops between 1886 and 1899, as well as five primary mills, two structural mills and six plate mills.When Carnegie Steel merged into the newly formed U.S. Steel Corporation in 1901, Homestead was producing more than 1.5 Mtpa of open hearth steel. This represented 25% of the total open heath steel capacity in USA, even though there were around 100 other open hearth plants operating, with around 400 furnaces.In 1892 Homestead was the site of the bloodiest union confrontation in the history of the American steel industry. A pitched battle took place between the Carnegie Steel Company and the Amalgamated Association of Iron and Steel Workers. Triggered by a company lockout, the union took possession of the Homestead plant and the company brought in some 300 Pinkerton agents in two barges in an attempt to secure the plant. When the Pinkertons tried to land at Homestead a huge battle ensued with significant loss of lives on both sides (at least nine strikers and seven Pinkertons). The state governor then sent into Homestead 8000 troops of the National Guard. The Amalgamated union was eventually soundly defeated and unions were largely banished from American steel plants for the next four decades.CARRIE BLAST FURNACESThe Carrie blast furnace plant was established by the independent Carrie Furnace Company in 1884. It was located at Rankin, directly across the Monongahela River from the Homestead Works. Carnegie purchased the Carrie furnaces in 1898 and soon began enlarging the two existing furnaces and building additional furnaces. The hot metal bridge linking Carrie furnaces to Homestead Works opened in 1900.Until that time, Homestead’s steelmaking shops were based on purchased cold pig iron, some shipped from Carnegie's two Lucy blast furnaces (on the Allegheny River on the northern fringe of Pittsburgh) and from the rapidly growing blast furnace complex a few miles away at Carnegie's Edgar Thomson works. After the construction in 1896-97 of four of the world's largest blast furnaces at Carnegie's Duquesne works, surplus hot metal was regularly railed from Duquesne to Homestead to feed the expanding open hearth shops. The ladles were insulated with a layer of coke dust during the 4 miles rail journey.No.1 BFMoved 1884 from Ohio, rebuilt 1893, 1901 & 1919. Last rebuilt 1925 to 22'6" hearth, later 23'. Closed 1970s.No.2 BF1889, rebuilt 1895, 1902 & 1919Last rebuilt 1925 (23') closed mid-1960s.No.3 BF1901, rebuilt 1927 (21'6")New No.3 built 1941 (26') increased to 28' in 1957, and to 29'6" (2600tpd) between 1968 and 1970. Closed 1984No.4 BF1901, rebuilt 1927 (21'6")New No.4 built 1942 (26') increased to 28' in 1959, and to 29'6" (2600tpd) between 1971 and 1974. Closed 1984No.5 BF1903, blown out Oct.1929, still dormant 1935, dismantled 1937-38No.6 BF (PRESERVED)1907, rebuilt 1926 to 21'6", 700tpd, and then 1937 to 23'6", 900-1000tpd.In 1970s producing 1000-1250tpd. Closed 1978No.7 BF (PRESERVED)1907, rebuilt 1926 to 21'6", 700tpd, and then 1937 to 23'6", 900-1000tpd.In 1970s producing 1000-1250tpd. Closed 1978Carrie sinter plant (built around 1950), 6' wide, capacity 1951 listed as 0.416 Mtpa of sintered flue dust, 0.635 Mtpa in 1957.Closed 1977.HOMESTEAD BESSEMER SHOP2 Bessemer converters x 4t 1881,Later 2 x 12t, closed 1906, demolished 1912HOMESTEAD OPEN HEARTH SHOPSNo.1 shop 10 furnaces,(built 1886/1889/1890/1902), recognised as the first commercially successful open hearth shop in USA.1886 4 x 15/20t (first 4 acid, later converted to basic), four more × 20/35t added by 1990, final 2 in 1902.In 1901 this shop had 8 x 25/30t furnaces in two parallel rows. In 1902 this was increased to 10 x 50t. The furnaces were at ground level, with below-ground circular casting/teeming pits shared between each pair of furnaces.Shop still listed 1945, closed and dismantled 1946.No.2 shop 16 furnaces.Built 1890 (8 x25t), 1895 (4), 1900 (4).In 1901 this shop had 16 x 40/50t furnaces in two parallel rows. This shop was also at ground level, with a below-ground ladle pit behind each furnace. Central transfer tracks allowed the steel ladies to be moved by locomotives to two circular below-ground teeming pits at one end of the shop. At the other end was a larger rectangular pit whose maximum ingot casting capability was 60 tons.By 1904 it was listed as 16 x 40/45t.Shop still listed 1945, photo being dismantled 1951.(Combined capacity of Nos. 1 & 2 shops was 0.75 Mtpa in 1890 and in 1945 0.78 Mtpa, one of these shops (probably No.1) closed by 1948, the other (probably No.2) by 1951.No.3 shop 24 furnaces(arranged as two parallel rows of 12 furnaces at ground level, each with a below-ground ladle tapping pit, then feeding to central teeming aisles)1898/99 24 x 45t (50t in 1901, 45t in 1904, 63t in 1926, 73t in 1945)(Capacity 0.9 Mtpa in 1901, 1.178 Mtpa in 1945)Closed 1953, dismantled 1954.No.4 shop 14 furnaces1906 10 x 55t , 1910 4 x 75t (79t in 1926, 106t in 1945, 145t in 1960). This shop was conventional 20th century design with furnaces in a single row on an elevated operating platform and tapping into ladles at ground level.(1.07 Mtpa in 1945, 1.6 Mtpa in 1960)Closed 1974No.5 shop 11 furnaces1943 11 x 225t (300t in 1960, 320t in 1980)(1.7 Mtpa in 1945, 3.0 Mtpa in 1960, 3.3 Mtpa in 1977)Closed 1984OHs built......4 in 1886 (No.1 shop), 3 in 1889 (No.1), 9 in 1890 (1 in No.1, 8 in No.2), 4 in 1895 (No.2), 10 in 1898 (No.3), 14 in 1899 (No.3), 4 in 1900 (No.2), 2 in 1902 (No.1), 10 in 1906 (No.4), 4 in 1910 (No.4), 11 in 1943 (No.5).1n 1901, according to S.T.Wellman, Homestead had 48 furnace of 40 to 50t each, total 1.3 Mtpa.By 1903 this had increased to 50 furnaces, 40 x 50t and 10 x 38t.HOMESTEAD STRUCTURAL MILLSThroughout its 105-year history, Homestead operated a total of five structural mills.When Carnegie acquired the Homestead Works in 1883, he consolidated rail production at his nearby Edgar Thomson Works and switched the Homestead rail mill to producing other shapes, including structurals.The original Kloman rail mill was built in 1881. It comprised a 30” bloom mill feeding a 23” rail train and attached billet train. By 1884 Carnegie had added a 30” train for structural shapes. A 38” bloom mill was apparently added sometime in the 1890s.Homestead's first dedicated structural mills were installed between 1886 and 1891. The first included a 33" bloom mill (1887) feeding a 33" 3-hi finishing mill (1886), rolling beams up to 24". It was closed in 1926/27. The second had a 40" bloom mill feeding 35" 3-hi 4-stand Mackintosh- Hemphill roughing and finishing mills rolling beams up to 36". The 35-inch Structural Mill, built in 1891, also closed between 1926 and 1927.In 1927 all structural output was consolidated in two new mills at a cost of $20M. No.1 took over all the output of the previous Homestead structural mills. It featured a 44" United bloom mill feeding a 36" Mesta secondary bloom/breakdown stand and a Mackintish-Hemphill 3-stand 3-hi 28"/32" finishing stand mill. Maximum standard beam size was 24". Capacity when built was 0.384 Mtpa. It was rated at 0.518 Mtpa by the late-1970s..The new No.2 Structural mill had a 54" United bloom mill (the world's largest at that time) feeding a new 3-stand 52" universal structural mill with reversing roughing and intermediate mills and a single pass finishing stand (mill supplier?). Maximum "Carnegie" universal beam size was 36". Bethlehem Steel successfully sued U.S. Steel for infringing the Bethlehem Grey Mill universal beam patents. Capacity when built was 0.584 Mtpa. It was rated at 0.731 Mtpa by the late-1970s.The two structural mills were shut down in 1985, but the No.2 mill was briefly reactivated in 1986.HOMESTEAD PLATE MILLSThroughout its long history, Homestead operated a total of 12 plate mills.Homesteads first plate mill was installed around 1886. It was a 119" 3-hi Lauth-type mill, described in 1890 as the widest in USA. It was installed as a southern extension to the No.1 open hearth shop. It was converted to an 84" width by 1906, around the same time that a wider 140" Mill was installed. A 1913 source said output was 0.1 Mtpa.A unique 32" combination universal slab mill/armour plate mill was built in 1888. It was adjacent to the No.2 open hearth shop and immediately upstream from No.1 shop. The armour plate rolling format was originally 3-hi mode. This was converted to 4hi universal format in 1891, with the horizontal rolls widened to 110". This was then possibly the world's first 4-hi rolling mill. It remained in operation for more than 60 years, closing in 1952.Bethlehem Iron Co. had installed three plate mills at its Bethlehem works around 1895-96. Bethlehem described them in 1897 as a 32" universal slab mill feeding a 26" universal mill (72” wide) and a 34" plate mill (3-hi Lauth-type 34" x 128"). All three mills were built by Mackintosh-Hemphill. Bethlehem soon decided to exit the plate business as it was uncompetitive. Carnegie purchased the mills in 1897-98 and installed them in the new Homestead 30-inch mill building complex. They were apparently reconfigured as the 30" universal slab mill, 42" universal plate mill and 128" 3-hi mill. The 30" slab mill was closed in 1945. The 42" mill (whose product range was largely duplicated by the 48" mill) was closed in 1933. The 128" mill was converted to a 118" mill in 1928 then closed in 1931. 1913 source reported 128" mill output was 0.170 Mtpa.Homestead's 48" universal plate mill was installed as a completely new installation at the same time, commissioning in 1899 (Mackintosh-Hemphill, steam driven). It was located close to and upstream from No.2 open hearth shop. It rolled slab ingots cast in the Nos. 1 & 2 open hearth shops. It was originally configured to roll universal plates 20" to 46" wide. Around 1930 the mill stand was replaced to roll plate up to 52" wide. It was closed December 29, 1979 after 80 years of operation. Capacity was rated at 0.204 Mtpa in 1935, and still rated at 0.250 Mtpa in the late 1970s.After the completion of its 42-inch universal plate mill (ex-Bethlehem) and the 48" mill, both in 1899, plus the 32” universal armour plate mill, Andrew Carnegie's Homestead Steel Works had the most extensive universal plate capacity in the World.After 1901, U.S. Steel soon added four more plate mills.A 140" 3-hi mill was added 1904 at the south end of the 32" slab/armour plate mill, rolling slabs from the 32” mill. It was replaced by the 160" 4-hi mill and shut down in 1945. 1913 report says output was 0.178 Mtpa.Also in 1904 the existing 119" plate mill was rebuilt as an 84" 3-hi mill (0.1 Mtpa 1913 report). Slab feed came from the 32” mill.A new 72" 3-hi mill was added in 1907 (0.045 Mtpa 1913 report), also fed by the 32” slab mill.The 110" "Liberty" 3-hi plate mill was rushed into service in 1917 to supply plates to the Emergency Fleet Corporation. It was the first Homestead mill to be electrically driven (4000hp motor). It was closed in 1937, having been replaced by the new 100” continuous plate mill.A $10M 100" United 7-stand continuous 4-hi plate mill was commissioned in 1936. The 100" Mill was essentially a wide continuous hot strip mill without the final two finishing stands. It rolled plate up to 98" wide and 5/8" thick. The roughing stand was rebuilt in 1941 from 90" to 120" width to roll wider plate for shipbuilding, by-passing the finishing train. The 100” mill was closed in 1985. Capacity when built was 0.900 Mtpa. It was rated at 0.980 Mtpa before closure in the 1980s.WWII DEFENCE PLANT CORPORATIONAs an emergency measure triggered by WWII, the Defence Plant Corporation funded a $90M project at Homestead, requiring a major acquisition of additional land. After 60 years of development, the existing site was extremely congested. The government acquired 120 acres of adjacent residential and commercial land including 1200 buildings with up to 8000 residents. This acquisition extended the Homestead site to 430 acres.The new DPC facilities included No.5 open hearth shop, the 45" universal slab mill, 160" plate mill, No.2 forge shop and other ancillary facilities. U.S. Steel purchased these units after the war for $63M.U.S. Steel separately funded a related wartime expansion, the 1941 and 1942 rebuilding of Nos.3 & 4 Carrie blast furnaces from 21'6” to 26' hearths.The wartime expansion boosted Homestead’s steelmaking capacity to around 5 Mtpa.No.5 open hearth shop with 11 x 225t furnaces (1.7 Mtpa) started operation in 1943 and operated until 1984. Capacity had been expanded to 3.3 Mtpa by the 1970s, based on extensive oxygen injection to reduce heat times.The 45" universal slab mill (United) was commissioned in 1944 and closed early 1980s. Capacity when built was 1.352 Mtpa. It was rated at 2.106 Mtpa before closure in the 1980s.The 160 " 4-hi reversing plate mill was built by Mesta in 1944, closed 1985. Capacity when built was 0.600 Mtpa. It was rated at 0.833 Mtpa before closure in the 1980sDECLINE AND CLOSUREIn the early post-WWII years, Homestead closed its three oldest open heath shops and all the rolling mills with the exception of the 45" universal slab mill (1944), the 160" plate mill (1944), the 100" continuous plate mill (1936), the 48" universal plate mill (1899) and the two bloom and structural mills (1927).Throughout the 1945 to 1985 period, Homestead received very little of U.S. Steel's capital investment, allowing the complex to decline into harvest mode. So by the time the crisis years hit the American steel industry in the late-1970s and early-1980s, Homestead was beyond saving.Iron and steelmaking was abandoned in 1982 and the plate and structural mills closed by 1985/86.From 1881 to 1984 Homestead produced more than 200 Mt of raw steel.Sadly the two preserved 1926-vintage Carrie blast furnaces are the only remnants of what was once one of the world's most famous steel works. On the opposite side of the Monongahela River, the entire Homestead site was demolished in the 1990s and replaced by an enormous outdoor shopping mall and office complex.The 1899-vintage 48” universal plate mill and its 5,850hp steam engine, however, were dismantled in the early 1980s and stored in a warehouse. After 20 years in storage, in 2014 the mill and steam engine components were moved to the empty Blowing Engine House building at the Carrie blast furnace historical site. The intention is to reassemble the mill and steam engine as an historic monument.The lessons from this??By the 1950s Homestead had two modern blast furnaces and four old units, one new very large open hearth shop and one shop more than 40 years old, and reasonably good plate and structural mills. But the problem was that both plate and structurals were no longer growth products compared to sheet and strip.In the 1959-62 US Steel invested heavily in a new blast furnace, LD shop and bloom mill nearby at Duquesne works, feeding special quality bar mills and also the tube mills at nearby National works. Within 20 years all of these primary end and finishing mills were closed. In the 1970s the old open hearth shop at the nearby Edgar Thomson plant was replaced by an LD shop to supply slabs to the Irvin hot strip mill. A modern high-capacity slab caster was added at ET in 1992 to replace the ingot casting-slab mill route.Investment in Homestead's front end might have been a better alternative, providing a central high capacity primary steel complex to supply semis to the Irvin HSM, Homestead plate and structural mills and Duquesne special quality bar mills. The Homestead USWA membership, however, was perceived to be still far more antagonistic towards management, as a heritage of the bitter 1892 strike. The local union branches at ET and Duquesne were considered to be far more cooperative.John GrovesOctober 2020, updated November 2021 13.5” on 2 strands and 20.125” on 2 strands. Actually worked great!

John Groves: But I am seeking help on one missing piece of this history....

"The new No.2 Structural mill had a 54" United bloom mill (the world's largest at that time) feeding a new 3-stand 52" universal structural mill with reversing roughing and intermediate mills and a single pass finishing stand."

I am a bit frustrated that I have never been able to track down which mill builder supplied the three 52" universal mill stands. Does anyone have a picture of these mill stands that might show the manufacturer's name?

Maybe there is someone who actually worked on this No.2 beam mill, as it was the last part of Homestead works to close in 1986.

Raymond Large: Made a lot of money working for American Bridge working in that mill......

|

| 2 |

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| John Murnan II posted Union RR Alco RS2 at US Steel Homestead. W. A. Feibelman photo |

|

| United States Steel Corporation posted Visitors to The Waterfront shopping district near Pittsburgh can easily spot the telltale signs that used to be #USSteel's Homestead District Works. And while most all of the buildings laid out on this 1965 map are no longer standing, history buffs can still marvel at the original venting stacks and venture into the Pump House built in 1892 by the Carnegie Steel Company. James Torgeson shared |

|

| Jeff Staymates commented on James' share In the center of this photo you can see the water tank that is still there today. |

|

| HAER PA,2-HOME,1- (sheet 3 of 7) Defense Plant Corp. Homestead Works, Site Plan, 1944 - Mesta 160-Inch Plate Mill, Defense Plant Corporation, Homestead Works, Homestead, Allegheny County, PA |

|

| Gerry commented on his post Kevin Tomasic: Braddock/Rankin PA border. The plant in Gary’s shot is the Carrie Furnace-now a historical site. |

|

| John Murnam II posted PRR E7’s passing the Braddock works, headed for Pittsburgh in 1949. W.A. Feibelman photo. |

|

| Steel Valley History posted |

|

| Bob Ciminel posted Carrie Furnace, at the time of this photo, had four furnaces with a capacity of 6,500 tons per day. The furnace hearths were 29.5 feet in diameter on two of the furnaces and 23.5 feet on the other two. The furnaces were 200 feet tall. The charge was 1.5 tons of iron ore, 0.5 tons of coke, 0.25 tons of limestone, and 2 tons of blowing air to make a ton of iron. Thomas Cavrak: The pictures you see are number three furnace and number four I work there from 70 to 73 what a hard place to work at. Tom Harvey: During WWII one of them set a record of 44,000 NTHM in a month. Now a well run furnace with a 28ft hearth can do that in 10 days. Which is probably why ET is down to two furnaces from the 12 or so it had in the early 1900s. Patrick Martin: What’s a typical product rate of pig iron now? Say in the ET furnaces? Tom Harvey: ET 1 & 3 can run 4-5,000 NTHM a day. I think Gary 14, which is much bigger, can do 8-9,000. John Groves: The old No.6 and 7 furnaces are preserved as historic monuments, but sadly the newer Nos.3 and 4 were demolished. It is sad that it was apparently not possible to preserve all four of the remaining Carrie furnaces, just like all five of the Bethlehem furnaces have been preserved. John Groves: Patrick Martin, here is the info for the two Edgar Thomson furnaces.... No.1 now 8.8m, 1541 cu.m. wv, producing 3300 to 3800 tpd over past decade. No.3 now 7.7m, 1380 cu.m. wv, producing 2750 to 3100 tpd over the past decade |

|

| Bob Ciminel posted Homestead Works 160-inch plate mill. Cleaned and painted for the company photographer. Hunter Jones: Who now runs a 160 inch plate mill? Will Jamison: Cliffs Burns Harbor Brian Olson: I was told Baytown Texas had the newest and most powerful 160" plate mill in the USA. Today it is run by JSW Steel. I was also told Homestead was the weakest of the plate mills at US Steel in terms of capabilities but at the end of the day it died the same year that Baytown did, 1986. Tony Pezzotti: Hunter Jones Algoma steel runs 166” plate mill. Glenn McCullough: Hunter Jones FYI the man in that pic is gauging the thickness of that plate ,it started out as a cherry red approximately 4'x8' couple feet thick slab they then kept lowering those giant rolls and rolled it back and forth until they met the spec . Brian Olson Joe Marc Baytown's 160" mill is still running: https://www.jswsteel.us/baytown/about-us/... I was told the 160" mill in Homestead ended up in India but that may or may not be true. Glenn McCullough: Les Campbell our crew would throw 5 or 6 shovels on the slab instead of 1 or 2 and when it ran though the rolls the explosion shook the rafters dropping years of accumulated red dust on Bigwigs white shirts !! Nick Hlavaty: Does "160 inch" mean plates can be 160 inches in width? Or is 160" the width of the rolls? John Groves: Nick Hlavaty 160inch is the length of the rolls. The maximum product width is usually 4 inches less, so in this case 156 inches. Lenny LenBug Stobaugh: We had a 206” mill at Lukens Steel in Coatesville Pennsylvania. Bernie Casto: Are the back up rolls the same size as the work rolls? John Groves: Bernie Casto The work rolls were 36" diameter x 160" long. The backup rolls were 59" diameter x 154" long. Rick Guy Evans: Without exception, work roll dias are always smaller than back-up rolls, in any application! Daniel Aubuchon: I worked at the 160/210 Plate Mill in Gary Works. |

|

| Bob O'Neal commented on Bob's post |

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| John Petruzzi posted 12,000 ton press homestead forge div Kyle McGrogan Possibly built at Mesta Machine Co.?? Rick Rowlands Built by Bethlehem but I think Mesta made replacements for the upper castings at some point. |

|

| John Petruzzi posted View of cylinder side of press |

|

| 3D Satellite |

Jim Richard posted two photos with the comment: "the 12,000 ton forging press today and yesterday Homestead Works."

|

| 1 |

|

| 2 |

|

| Rasky Bukowski, Mar 2018 [This photo is now small because the following photo is better.] |

|

| Mike Charles commented on a post |

|

| Digitally Zoomed |

|

| 1951 Pittsburgh East Quadrangle @ 1:24,000 |

|

| HAER PA, 2-HOME,2- Significance: Established in 1879, Homestead Works is one of six plants (Homestead, Edgar Thomson, Duquesne, Irvin, National and Clairton) which, until the collapse in 1982, comprised U.S. Steel's Mon Valley works. In 1883, Andrew Carnegie acquired the works and transformed Homestead from a Bessemer rail mill to a highly mechanized, fully integrated heavy products mill. Open Hearth No. 1 was the first facility for large scale commercial production of basic open hearth steel in the country. Homestead rivaled all other mills in structural steel production during the late-nineteenth-century. The armor forging plant at Homestead played a central role in the development of American sea power and the American military-industrial complex. Homestead was a leader in the use of machinery such as hydraulic and electric cranes to reduce labor and increase production tonnage. In 1901, Homestead, along with the rest of Carnegie Steel, was absorbed by the United States Steel Corporation in a consolidation of the steel industry. Expansion to meet the production demands of World War I and World War II generated important periods of change at Homestead. Also, during the 1920s U.S. Steel modernized Homestead's structural mills in an effort to stay competitive with Bethlehem Steel. Postwar technical developments at the Homestead Works included the commercial development of high-strength alloy steel plate. After the Korean War, the forge division tooled up to produce nuclear containment vessels and electric generator shafts. As a group, the structures and steel-making equipment from Homestead Works represented one of the nation's most important steel mills and the Mon Valley's status as the pre-eminent iron and steel center in the United States for much of the nineteenth and twentieth centuries. |

|

| 1 |

|

| 2 |

|

| Adam Piscitelli posted Another one from the archives taken at the Homestead Works and not dated. It was amazing what these men were able to do given the limited (by today's standards) technology that was available to them. Korey Henson: 1890s |

|

| 1 OH 5 on the left looking east High level bridge ramp in the foreground USS Homestead Works |

|

| 2 Looking east from across the river USS Homestead Works |

|

| Joe De Franco posted Rail switcher working the molds at Homestead in 1977. |

|

| Jim Richard posted O. H. No. 4 along 8th ave / 837 USS Homestead Works Robert M. Milko: OH 4 was still standing when I was there but long abandoned for OH 5 near the High Level Bridge. |

|

| Jim Richard posted Amity St. Gate O. H. 5 in the back ground USS Homestead Works |

|

| Steel Valley History posted [Some comments indicate this was OH #5. I believe OH is Open Hearth.] Vinnie Opdyke shared Shared from my local friends at Steel Valley History - US Steel Homestead Works. Ron Baklarz: acI wrote a lot about the steel industry in the Mon Valley. Give it a read you won’t be disappointed! https://www.amazon.com/.../B0CG79.../ref=tmm_pap_swatch_0... |

|

| Dennis DeBruler commented on Vinnie's share Are those the stacks that got preserved? https://maps.app.goo.gl/bb4hdwCoymzPJu8CA Jay Zimmerman: Dennis DeBruler yep 45" mill soaking pits. Vinnie Opdyke: Dennis DeBruler no. The ones in the pic shared by me are east of the Homestead Grey's Bridge and belonged to OH #5.The preserved ones are on the west side of the bridge. |

|

| Adam Piscitelli posted The 45" mill in the USS Homestead Works. I spent a few shifts shoveling scale and grease out of those pits while it was down for maintenance. Good times. Dave Pat Gibson: I took this photo. I was a Motor Inspector in the 45” mill. |

|

| Sean Brady posted Workers look on as the hydraulic shears cut 5 inch steel slabs at the Homestead Steel Works. 1907 Doug Blackburn: It is a colorized photo... a human took an educated guess at what the real colors were when the photo was taken. Those best-guess colors replaced black and white elements from the original image. Whoever colorized the steel missed the appearance badly... the steel had to be hot to cut 5 inch slabs. But the hot steel would have been nearly yellow in the center and orange as you move away from the center. The colorizer appears to have chosen a single shade of red with a little orange that looks unnatural for actual hot steel. |

|

| 1 |

|

| 2 |

|

|

| 4 |

|

| 5 |

|

| Adam Piscitelli posted All that's left of the soaking pits at the Homestead Works. I'm glad someone had the foresight to restore and preserve these as they dominate the Waterfront landscape and serve as a reminder of our steel heritage. Matt Wasco: From what I’ve heard they weren’t saved on purpose. They were filled with asbestos & keeping them intact was the better option. Ron Milko: Matt Wasco I heard the Mayor of West Homestead wanted them to stay. |

|

| Adam Piscitelli posted From an earlier post someone requested a night version of the soaking pit stacks at the Homestead Works. I made this picture 20 years ago before the restaurant was built in front of them. |

|

| Jacob Elliot commented on Adam's post |

|

| Phil Martin Photography posted These are The Stacks which are located in a parking lot off of 5th Ave in West Homestead. It’s between AMC and Longhorn Steakhouse. There are 12 of them which are 130 feet high. This was part of the Homestead Steel Works. Nick Pishnery shared Joe Kerner: They are stacks from the Open Hearth Furnaces that were there. [I knew a 12,000 ton press was preserved. I did not know about the stacks.] |

|

| Ralph Cappella commented on Nick's share Did you know you can see those stacks from Mt. Washington???? Here's a slide from my dad's collection taken from the upper observation deck, (I added a few references for scale...)... [Actually, this is a correction posted by Ralph.] Hope I got it "right" this time folks. Thanks for commenting on the slip-ups in my previous photo. From my dad's slides, taken from upper observation deck on Mt Washington... I's say, circa 50's or 60's..... I know Eliza was still around till '77 if that helps.... By the way, Hofbrau House has great beer!!!! [He was wrong about the stacks. What he thought was Homestead was really part of J&L.] |

|

| This photo has been moved to "US Steel: Edgar Thomson Works in Braddock, PA" |

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|

| Chad Bercosky posted US STEEL HOMESTEAD 1970. Mike Stephenson: Stopper rods in Ladles! Dave Kurtz: Mike Stephenson Vesuvius Rotolok stoppers! Homestead was Miles Sherman’s key account. I’ve spent time in that pit. [Some comments mention "running stoppers." I believe that is when they can't stop the flow of iron after the mold has filled up. Some comments imply that some teeming operations allowed the iron to flow as the ladle was moved from one mold to another. But most comments indicated that a running stopper was a big problem.] |

Carrie Furnace

|

| Bob Ciminel posted Carrie Furnace, 1911 |

|

| Nick Markowitz Jr. shared Jaison Viglietta's post A Fritz Keck painting of the Carrie Blast Furnaces in Rankin, as seen in 1946. Built in 1907 on the Monongahela River and operated until 1984. Iron made in the furnaces was transferred across the river to be made into steel at the Homestead Works. |

|

| Bob Ciminel posted Rick Rowlands: Hearth, bustle pipe and half of the shell of the furnace proper. |

|

| Raymond Boothe posted USS Carrie Blast Furnaces with connecting bridge (Dr. Raymond Boothe photograph). |

|

| Bob Ciminel posted Carrie Furnace, 1954. Will Jamison: Pig machine lower left. Ben Ruszkoski: Worked as an conveyer belt it would take the pigs up an incline at the top the conveyer would dump the pigs out of the mold. They were often used when the blast furnaces were producing more hot metal than the Bessemer or open hearths required. Armand Latour: Pitt archives? Bob Ciminel: Armand Latour Yes. Excellent resource. Hope they don’t cite me for copyright violations. Armand Latour: Bob Ciminel they won't. It's an open source public collection. As long as you do not profit from the images, you'll be fine. I spend untold hours looking at that archive. A good chunk of the photos are part of the William J. Gaughan Collection. But you can also search their archives with a key word like Steel. EDIT: When you click the link it will take you to the collection, despite the header saying otherwise. |

|

| Bob Ciminel posted Carrie Furnace, 1937. Dolfus Williams: Yes I was Stovetender in the Blast Furnaces at Inland Steel in East Chicago, Indiana for years, That's one of those Jobs you can learn something new almost every day. William Gawronski: Dolfus Williams I used to walk by when you were blowing out the stove pressure. Wow what a noice, had to put fingers in your ears. Plus remember the gas you can't smell it. That was a dangerous job you had. Dolfus Williams: William Gawronski yes a Stovetender did some of the Most Dangerous Things in All of Steelmaking ,like Cleaning Blowpipes with the Wind On ,You have a nice day William. Rick Rowlands: Those stoves were installed in 1937. Bob Ciminel: Rick Rowlands New stoves or completely new furnace? |

|

| Bob Ciminel posted Carrie Furnace stockpile, 1937. |

|

| Raymond Boothe posted USS Carrie Blast Furnaces-Rankin, Pennsylvania: View of the bustle pipe and iron runners (unkn/Dr. Raymond Boothe color enhancement and repair). |

|

| safe_image for CARRIE BLAST FURNACES NATIONAL HISTORIC LANDMARK |

|

TheInclineCarrie FurnacesCOURTESY OF RIVERS OF STEEL |

|

| Bubba Dubs posted Carrie Furnace #6, Swissville/Rankin Pa |

|

| Bubba Dubs posted Carrie….. |

| |

A 1936 photo of the Carrie FurnacesCOURTESY OF RIVERS OF STEEL |

|

| Bob Ciminel posted Carrie Furnace, Nos. 5 & 6 furnaces in 1946. These two furnaces have been preserved as historic landmarks and are part of the Rivers of Steel project. I was lucky enough to be on the first public tour of the site in 2007. The photo is by William J. Gaughan. Andrew Carnegie purchased Carrie Furnace No. 1 & 2 in 1900 to provide iron to his Homestead Works across the river. Carrie shut down in 1984. John Groves Michael Matisko: And Carrie #1 and #2 were originally built by the Carrie Furnace Company led by Henry Clay Fownes, who sold them to Carnegie Steel (when Fownes was told he was dying from “hardening of the arteries”). I think you will find Andrew Carnegie purchased the Carrie Furnace Company in 1898, not 1900. The hot metal bridge to Homestead Works was completed in 1900. The two original furnaces were rebuilt and enlarged in 1901 and 1902. Furnaces Nos 3 & 4 were added in 1901, No.5 in 1903 and Nos 6 & 7 in 1907. There are lots more details of the Carrie furnaces and all the historic Homestead steelmaking furnaces and mills in this recent post.... Fownes, who lived until 1935, took up golf in his retirement, and finding the Pittsburgh-area courses to be insufficiently challenging, proceeded to found Oakmont Country Club—which to this day remains one of the most difficult courses in the world. Jon Matrozza: I worked at Edgar Thomson when they still shipped molten iron from Carrie Furnace to ET through Braddock PA after Homestead Works was idled. I knew some great furnace foreman from there as well,like Bob Roth he was featured on a Rick Sebak special on PBS. He lived and breathed iron making. RIP Bob. |

|

| Bob O'Neal commented on Bob's post Carrie Furnaces No.3 & No.4, 1949. |

|

| Bob Ciminel posted Carrie Furnace, 1949. |

|

| Bob Ciminel posted Carrie Furnace, 1944 |

|

| Bob Ciminel posted Richard Paterra: What are we looking at here? Dennis DeBruler: Richard Paterra Quoting the text on the photo: "Carrie Fce. #4 View Of Sand Beds Before Tapping Salamander, 7-24-41" It looks like they are going to make some rather large pigs of pig iron. Note the workers in the middle preparing the main channel and all of the white shirts on the left side watching them. |

|

| Bob Caminel posted Carrie Furnace, 1950. Hank Kalkbrenner: Old stoves Rick Rowlands: Carrie 3 and 4 Bob Ciminel: Are the stoves arranged in series with one discharging into the next or do they all heat a portion of the blowing air? Hank Kalkbrenner: Each stove is fired up to maximum temperature one hot stove in put on line then cold stove is taken of then put on gas always put one on before taking one of |

|

| Bob Caminel posted Carrie Furnace, 1954 (a retirement, I presume). |

|

| Rick Rowlands commented on Bob's post Looks like they were standing near the scale house with No. 1 in the background. |

|

| Bob Ciminel posted Carrie Furnance, date unknown (Looking at the hopper car, I'd guess early 1900s). Gary J Condon Sr.: That is the old car dumper, not sure when new one was built but I would guess the early fourties. US Government piled money into Carrie to upgrade facilities during the war, they built #3 Powerhouse, the new stoves for #2 and the steam shed. |

|

| Bob Ciminel posted New furnace going in at Carrie Furnace in 1954. Rick Rowlands: This is the set of new stoves and stack for No. 2. What is odd is that they are pouring three stove foundations yet only completed two stoves. Jim Hewett Jr.: An added bonus for me is the mixer truck. Trucks & steel mills are 2 of my favorite things. [Ready-mix trucks were a new thing in the 1950s.] Dean F Harmon: There's almost as many white shirts with hands on hips as workers. |

|

| Bob Caminel posted, cropped Carrie Furnace, 1955. Carsten Lundsten: How late were they using padlewheelers? James Torgeson: Yeah, they operated later than most believe. The Corps of Engineers had one late as well. They were excellent for shallow water and floating obstacles. Andrew Stewart: Carsten Lundsten oh I know. Commercially they used them into the 80's. Especially on the Allegheny. |

|

| Bob Ciminel posted Carrie Furnace, 1964 |

|

| Bob Ciminel posted Carrie Furnace, 1966 |

|

| Bob Ciminel posted Carrie Furnace turbine-generator. Ed Goyda: There were 2 at Carrie one larger than the other. When they shut one down the other was already on line. Took the better part of a week to stop turning. Randal McVaney: Ed Goyda on shut down would coast to stop in about 2 hrs , when stopped would put on turning gear until turbine exhaust temperature was less than 180F to avoid turbine shaft from sagging. Gary J Condon Sr.: It was an Allis Chalmers in #3 power house. Produced 25 cycle AC power, 900 Psi steam inlet. Bob Ciminel: Gary J Condon Sr. Pretty high steam pressure. Probably superheated too. Gary J Condon Sr.: Bob Ciminel Thinking back, might have been 600 psi and 900 degrees. Bob Ciminel: That’s a new unit. No oil leaks, charred paint, or coal dust yet. Ed Goodale: Most turbine decks are that way. Never seen a dirty one (unless we were tearing it apart) then it got dirty but was clean when we finished. I think a lot of turbine work is cleaning stuff.I did tons of it in my career William B. Hearn shared Not my picture., from another group, Steel Mill Pictorial. Says it is the Turbine-Generator at the Carrie Blast Furnace Power House near Homestead, PA. Carrie Furnace is now open to the public for tours. The Turbine-Generator is no longer there. This may have been a 25 cycle unit. |

|

| Bob Ciminel posted Carrie Furnace Open House 1946. |

|

| Bob Ciminel posted Carrie Furnace open house, 1946 |

|

| Bob Ciminel posted Carrie Furnace open house, 1946 |

|

| Donna Rose posted James Torgeson: CVN-65, launched in 1960? Donna Rose: James Torgeson WWII James Torgeson: Donna Rose Not a 1930s photo, as the WW2 Enterprise (CV-6) was launched in 1936. Donna Rose: James Torgeson this picture is from the 1960s. My father is in the back row. Not sure the details. I assumed it was the one in World War II that they were dismantling. I'll have to research. This is what was written on the picture. |

|

| Steel Valley History posted Carnegie-Illinois Steel Co, view from Munhall Gardens. Wayne Cunningham: You can tell this end of the mill was idle. No smoke from the stacks. The large stacks were probably OH 2 or 3. OH 4 started at the bottom of Library St. where Wendy’s is now. [OH is probably Open Hearth.] Rob Craven: When I worked in Homestead Works in the 70s and 80s, a lot of the cranes had placards in them stating "Property of Carnegie-Illinois Steel Corporation." Randy Wolfe shared Randy Wolfe: Blast Furnaces, (Carrie Furnaces), were located across the river in Rankin, PA and connected to the main plant by a hot metal railroad bridge. |

|

| Abandoned America posted One of the abandoned blast furnaces at the abandoned Carrie Furnaces in Rankin, PA. The Carrie Furnaces are nearly all that is left of the massive U.S. Steel Homestead Works, and thankfully are being preserved for visitors now by the nonprofit Rivers of Steel. https://www.abandonedamerica.us/carrie-furnaces Abandoned America Carrie Furnaces is a chapter in my first book, "Abandoned America: The Age of Consequences" which can be ordered from any bookseller or directly from me below. If you like reading about pitching dynamite off a bridge at Pinkerton strikebreakers, this chapter is for you. https://www.dismantlingthedream.com/.../signed-copy-of... Allen Pugh shared |

|

| Gabina Onthe Road posted while takin the tour @ Carrie I was thinking this is all so cool ..and then you step into this space. felt like the should be playing the 2001: Space Odyssey music Joe Dolan: Cleanest casthouse floor that i have ever seen. Stephen Cussen: Joe Dolan A few volunteers had something to do with that back in early 2010s. The guys spent a whole weekend shoveling and sweeping the cast house floor and then power washing it. With no utilities, we drafted the water out of the Dorr thickener between 6&7 furnaces for the power washer. I was amazed how well it turned out. I was on premise at the time, doing other cleaning duties around the site. Jay Garner: And that’s just a little one ! The steel mill is a place that cannot be described unless you’ve actually been there ! It is a behemoth place that even after years of being around every operation of it like I have seen , it still makes you say …. Wow Scott Jordan: Jay Garner it’s amazing the number of new hires walk out on their first day, you turn around and their GONE. Johan Dzankuhwitz: If you've ever been around one running, there is only one sound that is associated with that picture, and it ain't music... |

My last scan from the Homestead Works brochure is a three-page foldout showing the flow process through the works.Homestead poured its first heat of steel in 1881. When the brochure was produced 9,000 people worked at Homestead and produced 2.5 million tons of finished steel products annually. Homestead steel was used in the Empire State Building and the John Hancock, Sears Roebuck, and Standard Oil skyscrapers in Chicago.I hope you enjoyed this series on one of the largest steel producing facilities in the United States.Bob Ciminel, Pawleys Island, SC

|

| 1 |

|

| 2 |

|

| Ray Schloss posted This map of where the mills were is from 1990. John Groves: Thanks to Ray Schloss for this very valuable map of what was once the steel capital of the world. Almost all of it has gone, and the long-term future of the last integrated iron and steel plant is deeply in doubt. Andrew Carnegie's Edgar Thomson plant was the world's first fully integrated plant, built in 1875, and now approaching a century and a half of continuous operation. Lyle Zerla mentioned 450 blast furnaces in 1960 within a 50 mile radius of Pittsburgh. I suspect maybe this figure was more likely to be open hearth furnaces, not blast furnaces. In 1960 the total number of blast furnace in the entire USA was 263. Of these, 76 were in Pennsylvania and 52 in Ohio. In 1960 there were 906 open hearth furnaces in USA. Pennsylvania had 283 and Ohio 169 (totalling 452 furnaces). The map shows eight separate integrated steel plants strung out along the Mon Valley. By far the largest and probably the most famous was the huge Homestead Works which had seven BFs, five open hearth shops with a total of 75 furnaces, and a line-up of structural and plate mills. I published a detailed facilities history of Homestead here last November.....[see way above] Guy James asked about the historic steel operations at Clairton Works. James Torgeson accurately responded that Clairton produced structurals and similar products. Clairton became the world's biggest coke plant in the decade from 1918, with a total of 22 batteries. But ironmaking, steelmaking and rolling mills had been established at Clairton in 1902 to 1904 by the St. Clair Steel Company to supply quality billets to its associated Crucible Steel Company. Clairton plant was acquired by US Steel in 1904. The plant had three blast furnaces, a 12-furnace open hearth shop, bloom & billet mills, three medium & light structural mills and a bar mill. Annual steelmaking capacity was 1 million tons in 1960. The three small BFs were closed between 1959 and 1962. The open hearth shop, bloom and billet mills were closed in 1962. The bar mill was closed in 1977 and the three structural mills survived until 1984. The map shows US Steel's Donora Works south of Clairton. It was very similar in scale and timing to Clairton. Established by Union Steel in 1899 with backing from former Carnegie partner, Henry Clay Frick. It was the world's largest rod and wire mill and was acquired by US Steel in 1902. It had two BFs, a 13-furnace open hearth shop, bloom & billet mills, three rod mills and wire mills. Annual capacity was 1 million tons in 1960. Iron and steelmaking was closed in 1962, with rod and wire mills closed in 1966. Bob Daykin: Peak employment in steel (IIRC) was in 1977-78. [USS also had a plant in Etna, PA.] |

|

| Adam Piscitelli posted in Homestead, PA This is an ingot buggy probably from OH4 where I worked as a greaser. The cars got so hot from the molten steel that the grease ran out or caught fire in the journal boxes on the axles. My job was to pack the axles with grease balls which were softball sized wads of scrap yarn soaked in grease. Spent a lot of time on my back stuffing wads into journal boxes. Added bonus: the cars were still smoking hot when we got them. Al Monroe: did you use regular like mayo consistency grease or did you use thinner stuff like when grease separates. Adam Piscitelli: Al Monroe Thin. Like maple syrup. Al Monroe: Adam Piscitelli oh ok. That's what i figured. Great story. Love to listen/read old industry stories. Ralph Tramontana: I worked at the soaking pits for a summer at National Tube in McKeesport. I was amazed that the train would pull the ingots all the way from Duquesne without them falling off the car. David Lang Jr.: Where is this displayed Dennis DeBruler: It is in the corner of a little park at 8th and West Streets, https://www.google.com/.../@40.40633,-79.../data=!3m1!1e3... |

|

| 33:10 video @ 1:30 Hundreds of Carnegie's Workers Watched the Steel Turn Molten—and Never Came Home Carnegie’s steel mills helped build America in the late 1800s, but inside those furnaces and rolling floors, men faced heat, machinery, and exhaustion that killed more workers than history ever recorded. This documentary uncovers the untold dangers, the hidden death toll, and the brutal reality behind the steel that shaped the nation. |

Good post. I never would have read about the history of Braddock without reading this site.

ReplyDelete