|

| Laurie Schulte posted Mesta Machine Company postcard - circa 1909 |

|

| James Bost posted THIS GROUP OF POSTCARDS ARE OF 4 OF OUR LOCAL MILLS.USS ET BRADDOCK,CARRIE FURNACE RANKIN,USS HOMESTEAD WORKS & MESTA MACHINE HOMESTEAD.FROM ORIGINAL PAINTINGS OF HOWARD FOGG,LATE 1950s |

After a decade, a new office building and another shop building along the tracks.

|

| Smithsonian Institute, p8, 1919 Adam Piscitelli posted The Mesta Machine Company in 1919. Manufacturers of some of the finest heavy machinery for the iron and steel industry. Kenneth Treharn: Youngstown, Ohio had United Engineering, Wean, Bliss and McKay Machinery. All made great Steel Mill Equipment. All gone. |

|

| David Mancak posted Mesta Machine, now Whemco, owned now by Park Corporation, they also bought the Homestead Works and tore in all down... Hemi Joe: Ray Park is the "Tear Down King". 😡 |

|

| Robert Meyer commented on Adam's post Burns Harbor 50 X 96 Slab Mill, built by Mesta. |

|

| Jack Vavrek Mesta Machine West Homestead Pennsylvania |

|

| Mike Theisler commented on James' post |

|

| John Cooper posted This was another Mesta Mill we installed in 1954. We used to deliver 8" x 8" Blooms to the Billet Mill, and these 2 stands allowed us to deliver 10" x 10" Blooms, saving 2 passed on the Blooming Mill. |

|

| Paul Mayhew commented on John's post 80" in Mingo Ohio. My father and I worked there. It's also shut down. |

|

| David Janusek posted Mesta Machine, West Homestead PA |

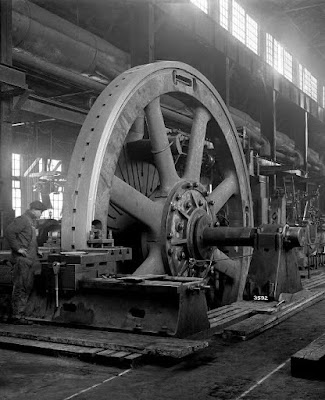

Mike Bready posted two photos with the comment: "Found these prints years ago,decided to share. ( Mesta ) not sure what type of lathe it is but it’s of good size for sure."

David M Stockett: I also believe that machine was installed by the govt. During WW2 to bore the barrette gun barrels.

Michael Stadler: She is a beast...located at mesta (WHEMCO) In Homestead PA. Was part of the crew who retrofitted it back in 2008..got upgraded w Siemens 840D cnc for the remaining saddle 1...

David Finch: To me the most amazing part of Mesta was the ability to build machinery needed to machine the Mill stands and housings that were ever increasing in size. [Every time I see a huge machine tool I think: but how do you make that machine?]

David M Stockett: I Worked there for 10 yrs, I remember that machine. I don't remember the stats, but it would bore a 8" center hole thru rolls, columns, etc. As a welder, I had to cut the cutting head off for a new one. The guy that ran that machine worked 5a - 7p everyday...

William Wimer: They called it 100 it lath it was built by mesta machine still at Whemco that machine is tree panning Emile, ROLL pouring out the center

Stacy Mays: I think they used to make shafts for the props of ships on them too.

Carl Mark Chapmon: We had lathe that were bigger they spun four hundred inch OD for turrets for battleship has name engraved on machine. It was huge machine

|

| 1 |

|

| 2 |

|

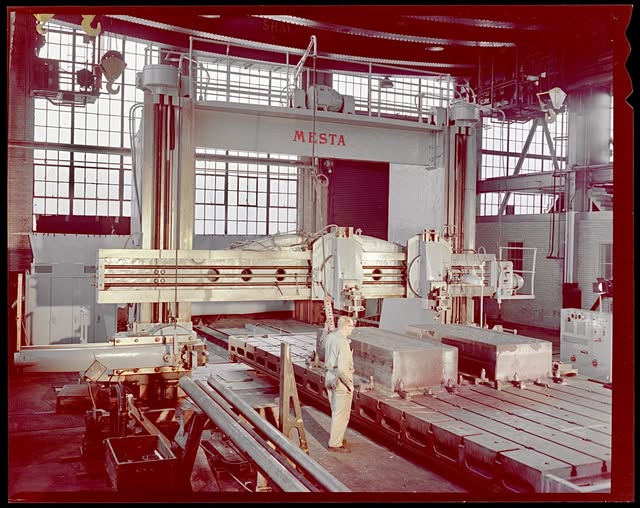

| Mike Theisler commented on Mike's post |

|

| William Wimer posted Mesta machine gunbarrel Joseph Lordeon: Mesta was located in W Homestead Pa. Pearl Mesta was an heiress and owned Mesta. When Japan bombed Pearl Harbor Mesta was still shipping barrels to Japan. The National Guard finally arrived and Japan shipments stopped. Tim Hanlon: Where was this? William Wimer: Tim Hanlon Mesta machine West Homestead PA |

|

| William Wimer posted, cropped Mesta mil stands |

|

| Sean Brady posted Machining a gear at the Mesta Machine Co, WestHomestead,c.1910. The size and scale of steelmaking technology at the turn of the century fueled the almost overnight industrialization and urbanization of many parts of the country. Today, that same technology presents a new set of challenges for those who hope to preserve it. [The comments discuss why it was cast with two halves.] |

|

| Senior Big Machine posted Molded Staggered Tooth Gear, Mesta Machine Company, West Homestead, Pennsylvania, 1913 ! Images of Yore posted A Mesta Machine Company employee stands next to a molded staggered tooth gear at the company’s West Homestead PA building, in 1913. |

|

| Jim Rickard posted Mesta Machine 1913. Mesta supplied heavy steel mill machinery for mills all over the world, this is the type of giant forgings and castings Mesta was famous for. Graham Whitfield: There is a great story about Mesta and a British Steel Company called John Summers Ltd. ( A large family owned Steel manufacturer.) In 1936 they began preliminary negotiations with Mesta regarding installation of Hot and Cold Continuous Mills to replace obsolete Hand Rolling Mills. In 1937 the Chairman of Mesta finalised the deal at the Savoy Hotel in London with a written estimate of $10 million on Hotel Stationary and a handshake. The Mills were commissioned on time and on budget and with strategic timing before the outbreak of WW2 in September 1939. Stephen Mcnally: the 42 and 48 inch steam beam mills in bethlehem came from mesta in 1907. [A comment indicates that Mesta was founded in 1898 in West Homestead, and they opened their New Castle plant in 1942.] |

|

| John Derry commented on Jim's post My Uncle John Worked there!! |

|

| Skip Estes commented on Jim's post I was a welder at Wyman-Gordon years ago, they had Mesta presses and this 50,000 ton Loewy press. Impressive |

|

| Be Grassel commented on Jim's post |

|

| John Monter commented on Jim's post This is the 50,000 ton forge press they made back in the 50’s. Biggest in the world at the time. |

|

| James Mitchell commented on Jim's post A big one I put the bearings and coupling on a few years ago. |

|

| Steve Herrmann commented on Jim's post That’s a 8’ladder next to this bull gear. It drives a furnace at a BOF |

|

| Mike Theisler commented on Jim's post |

|

| Daniel Rush posted 1913 - Mesta Machine Staggered Teeth Gears |

|

| safe_image for Photo 1913 Mesta Machine Double Helix Gear |

|

| safe_image for Photo 1915 Mesta Machine Machining a Crankshaft |

|

| Harry Bolton commented on the above post SO you think it's 1915 hahaha [Don't you just love comments that don't provide the correct information?] |

|

| safe_image for Photo 1915 Mesta Machine Turning a Fly Wheel on a Pit Lathe [Harry Bolton had a comparable comment on this photo as well.] |

|

| safe_image for Photo 1915 Mesta Machine Vertical Turning Machine |

|

| safe_image for Photo 1915 Mesta Machine |

|

| safe_image for Photo Mesta Machine Machining Casting |

|

| safe_image for Photo |

|

| safe_image for Photo Mesta Machine Turning Naval Shafts |

|

| Sean Brady posted Mesta Machine Company workers dwarfed by machinery, West Homestead 1940S Mesta Machine Company worked on a huge scale producing equipment used in steel mills and other manufacturing plants. Founded in 1898 when George Mesta merged two smaller companies, it became the world’s largest steel equipment manufacturer under one roof. The company made crushers, engines for blast furnaces, molded gears and massive forging presses, products that towered over the workers who created and operated them. [There are some interesting links in the comments about big presses.] |

|

| Jonny C Brando commented on Sean's post [There were some comments about wanting to what machined the top piece of the hydraulic press.] |

|

| Adam Piscitelli posted A Mesta blooming mill under construction. Illustration is from the 1919 Plant and Product catalog. Here's the link to the entire catalog: https://archive.org/details/plantproductofme00mest/mode/2up Denny Paderewski: I like the way that they assembled everything before they shipped it.. Rick Rowlands: Denny Paderewski all machinery was assembled first in the shop then disassembled and shipped. |

|

| Joean Ngew posted " Double Helical Cut Tooth Mill Pinions. Mesta Machine Co. Circa 1920-25 " Ray Obrien: Double helical HERRING bone gears is more like it. [At first, I didn't notice the man standing on the right side of the photo. He is important to provide scale.] Jon Wolfe shared |

|

| safe_image for Photo 1920 - Mesta Machine Engine 🚒 Shaft |

|

| George Davidson commented on Sean's post Dont forget there was more below. |

|

| Robert Meyer posted One of my favorite Mesta themed photos. Delivery of Mill post, 50" X 96" Slab Mill Burns Harbor. Photo in 1968. Burns Harbor's Slab mill began operation on October 20, 1969. [Additional comments explain this slabbing mill was closed after both of the continuous casters were working.] |

|

| Misbahudin Misbah posted 1901 mesta machines 72" lathe👍 |

|

| Sean Brady posted Checking diameter with a large micrometer at Mesta Machinery - 1940s |

%20At%20The%20Controls%20_%20Checking%20diameter%20with%20a%20large%20micrometer%20at%20Mesta%20Machin.png) |

| Comments on Sean's post |

|

| Sean Brady commented on his post Here is a big caliper… |

|

| Brian Olson posted, at Facebook resolution A former Mesta engineer once told me "You can't separate engineering and manufacturing. It just doesn't work". I agree. |

|

| Sean Brady posted Watertown Arsenal (Mass.), "Mesta" machine bldg. 311 April 8, 1960 David Mann: Planer - Planing Machine. Shaping Machines big brother. Mark Hosbach: Looks like he’s squaring up a couple of forging die blocks. Did they have a drop forge at Watertown? |

Mara 12, 2024: Dean Amrhein posted the comment: "I have heard that WHEMCO in West Homestead, Pa. is closing. They are the last remnants of Mesta Machine."

Kenneth Treharn: Back in the day, I worked at WCI Steel, 56" Hot Strip Mill. We used only WHEMCO rolls. Great rolls. We got a new bean counter back in the 1990s and he had a brainstorm. They bought some "foreign" rolls and he cut back on the Standing monthly order with WHEMCO. The foreign rolls were beyond Junk. Back then, Companies were waiting in line to get WHEMCO Rolls. It took a while to get back to receiving our previously standard order. We were scrambling to keep production filled. Imo, WHEMCO were the best.

No comments:

Post a Comment