| |

| OnlyInYourState (source) 7. The Allegheny Ludlum Steel Corporation in Brackenridge in 1942. The photo, taken by Alfred T. Palmer, partially shows the plant in which steel workers turn scrap iron and steel into steel alloys. Jackson-Township historical preservation posted

Karl D. Swigart posted Allegheny Ludlum Steel Corporation, Brackenridge, PA Cary Goose Gossett: This one is still running strong. Stephen Glaister: Cary Goose Gossett idk if I'd necessarily say strong lol Cary Goose Gossett: Stephen Glaister I’m not working 60-70 hours a week because business is slow, but I guess it could be a matter of perspective. |

|

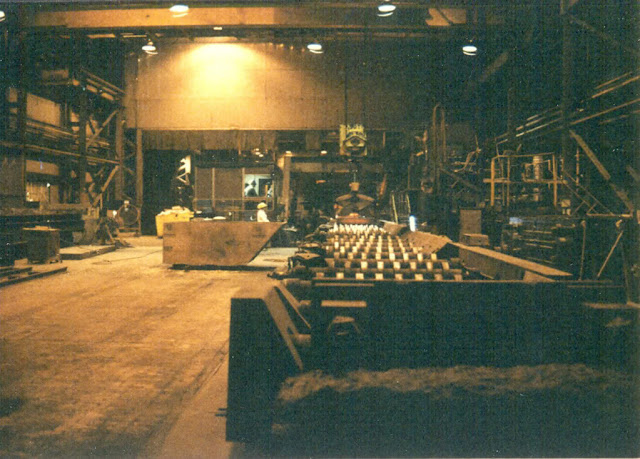

| Bob Ciminel posted Allegheny Ludlum, Natrona, PA Rich Headley: It had to of been taken in the mid 60s when they opened the melt shop. The repair shop had not been built yet and the paint on the coupla duct work still looks like new. I worked there till they shut it down in 2010. Real Bubba: The town in the middle, Natrona was a company town owned by Pennsylvania Salt Manufacturing Company, started in 1850 and produced salt until 1959. Across the Allegheny River at the dam is Braeburn Steel, two of the first Heroult EAF furnaces in the US. This little stretch of river towns is rich in industrial heritage, and that’s not mentioning the birth of ALCOA in New Ken, aluminum town just around the bend in the river at top of picture. |

|

| OnlyInYourState 8. Members of the United States Armed Forces watch as a machine at Allegheny Ludlum Steel in Pittsburgh turns steel into military weapons and equipment. Photo taken by Alfred T. Palmer in 1942. |

Yet another steel mill in Pennsylvania. But this one is along the Allegheny River instead of the Monongahela River.

|

| John Kubla posted West Penn Steel, Brackenridge, Pa. Combined with Allegheny Steel, then Allegheny Ludlum. |

|

| John Kubla commented on his post Bill Straka: John Kubla about 300 work there now. |

|

| Jeff Arthur Knorek posted "White-hot steel pours like water from a 35-ton electric furnace at Allegheny Ludlum Steel Corp., Brackenridge, Pa.". 4x5 Kodachrome transparency by Alfred Palmer for the Office of War Information. |

Arthur Godfrey posted ten photos with the comment: "ATI Brackenridge, PA. Hot Strip mill. 84" wide, 7 finish stands. Capable of reheating and rolling a 40' long slab. This is what 1.3 billion dollars buys you."

Jim Ordich: That Hot Mill was built to run 60 " Slabs from the Midland Plant and they shut down the Midland meltshop and caster.

Ron N Kay Brewer: Are those walking Beam furnaces?

Arthur Godfrey: Ron N Kay Brewer Yes.

Donald Esenwein: Pretty similar to the 84” in Cleveland. They can run over 300,000 tons a month! And roll some of the biggest gauge in the country.

Laurence Cox: Donald Esenwein the hot strip mill at Middletown can bang out 500,000 tons in a month.

Mark Dinzeo: How many jobs were eliminated as a result of the new technology?

Arthur Godfrey: Mark Dinzeo Many. At least half the man power to run.

George Paul: I'm one of the bricklayers that built the furnace in 2012.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| Corey Pometo commented on Arthur's post Finish mill |

Raymond Rieser posted three images with the comment:

Birthplace of Allegheny Ludlum Industries. Brackenridge, PAPlease click on photos to enlarge and read texts.From the files of the Alle-Kiski Valley Historical Society Museum located in Tarentum.

|

| 1 |

|

| 2 |

|

| 3 |

|

| Raymond Rieser posted Pouring steel Allegheny Steel Co. Mill Brackenridge, PA From the files of the Alle-Kiski Valley Historical Society Museum located in Tarentum, PA Will JamisonThat is an interesting setup, never seen one like it. Looks like it's designed to tap right out of the furnace itself, spout above ladle on left side. Not sure how slag was handled though. Buggy is chain driven from the opposite end which implies electric or steam power. Lances on the left are preheating the molds in the pit. Blocks on the rail right foreground. Placed on either side of wheel to keep buggy from moving while tapping. Complete lack of protective gear is evident. Cool post. |

Bradly C Jacob posted five photos with the comment: "Had to see what the view was like in the 135' manlift before the rental company takes it back. ATI Brackenridge, PA."

Dan Gatlin: Was this known as Allegheny Ludlum Steel at one time?

Phil Jadlowiec: Dan Gatlin yes

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| Andrew Edmonds posted ATI Brackenridge, PA. 2015 |

|

| Jay Rupert posted |

|

| 1 of 8 photos posted by Ron Wadowsky ATI Brackenridge HRPF at startup in 2015. Reversing Rougher Dennis DeBruler: HRPF = Hot Rolling and Processing Facility[more photos] Ron Wadowsky: This mill was designed and built by Siemens VAI, now Primetals, and including, mechanical, electrical and software. Anthony Barbaro: I was one of the 1st ones there, before it even was done being built. A group of us from the old hot strip mill got incumbency and we got it working. This thing can consume a lot of steel very fast. Kristopher Boyer: Spent alot time there erecting that facility. 26 acres under roof. |

Jay Trudgen posted three photos with the comment: "A few more shots from inside the continuous caster department of AL steel in Brackenridge, PA. These, and the other interior shots from last week, were taken probably around 1990."

|

| 1 |

|

| 2 |

|

| 3 |

|

| Mike Stesiak posted Brackenridge Hot Strip Frank Jay Roberts: Nice looks like automatic roll change capable. Arthur Godfrey: Frank Jay Roberts Yup , all at once and it takes minutes. |

|

| Arthur Godfrey commented on Mike's post new [I wonder how often they have to replace the rolls.] |

|

| safe_image for ATI's $1.2B hot strip mill in Harrison marks 10 years, remains world's most powerful, company says "Operations are fully automated inside the Hot Rolling and Processing Facility (HRPF), a $1.2 billion plant marking 10 years in Harrison along the border with Brackenridge. It’s the heart of ATI’s Specialty Rolled Products division." |

No comments:

Post a Comment