|

| Maritime-Executive Interlake Orders First New U.S.-Flagged Laker Since 1983 [This increases Interlake's fleet to 11 vessels. Canadian companies bought five new Lakers from China after Canada removed the 25% tariff in 2011.] |

Lance Zabrowski is at Bay Shipbuilding, Fincantieri Group. Sturgeon Bay, WI, United States ·

Bay Shipbuilding tour-the actual size is hard to describe-and pictures don't capture the massive machinery used to make these ships. Tours were given mainly by retirees with 30-40 years of service in the yard-great time, beautiful day, learned a lot, saw some awesome behind-the-scenes places that I can usually only see from outside the fence.

|

| 1 Bow Thruster Brian Ferguson That's a baby bow thruster. Somewhere on Boatnerd there's a picture of 3-4 people in one of the Bay Ship 1000 footers. |

|

| 2 |

|

| 4 |

|

| 5 Large two sided robotic welders for making 2 layer sections of the sides of ship. You can see the 4 welders on the right side of the gantry |

|

| 6 Graving dock with tug boat in for modifications that mates with a barge they are also making which you can see in the background |

|

| 8 Big Blue Gantry crane, 170 ton lifting capability-Made by Manitowoc Crane. They are replacing this one in the near future. |

|

| 9 Shipyard layout |

|

| 10 Indoor storage/sail loft |

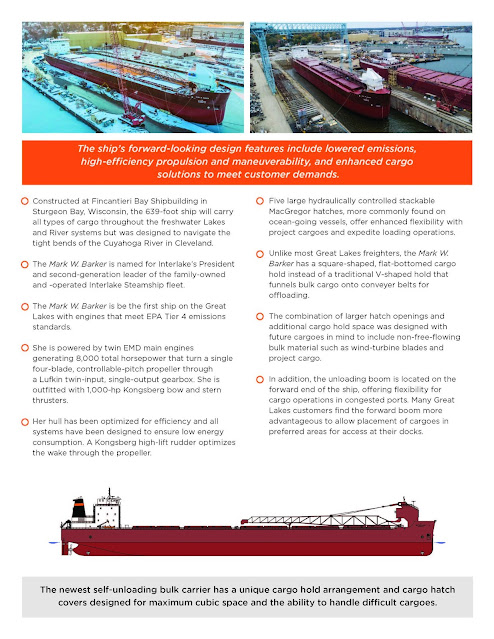

Hull 788: The M/V Mark W. Barker

Zach Wassermann Ward Posey to compete in the cuyahoga trade. That fwd boom on a river boat is going to help the mital upper dock in Cleveland towards the end of the season when the dock is full.

|

| One of 14 photos posted by Gary Cihlar [Look at all of the modules on the left side that are ready to be installed. And the self-unloading boom in the left side of the dock looks like it is ready for installation. It never occured to me that the dry dock would have to be wide enough to accommodate the freighter and long accessory pieces.] |

|

| safe_image for Photos: Float Out of First U.S. Built Great Lakes Bulker Since 1983 [They are freeing up the drydock for winter overhaul.] |

|

| maritime-executive "The next phase of the construction, which will continue throughout the winter, will be focused on the vessel’s auxiliary machinery, electrical equipment, piping, and electrical wiring installations. Ashore, shipyard workers will continue building the forward hull and bow section, the loop belt casing, the accommodation structure, and the casing and funnel structural sections." |

|

| Sreenshot Our new build being floated back into the dry dock today at Fincantieri Bay Shipbuilding! It’s her second time in the water as construction continues. She is expected to be underway in Spring 2022! |

This might be a launch from Fincantieri's main shipyard in Italy:

Side video, watch the waves rock the piers and boats

Stern video

|

| I reproduce the tenth photo because it also shows the Roger Blough. |

|

| Satellite |

8 photos of the last section of the bow being added

|

| Interlake Steamship Co. posted [It was launched on Oct 28, 2021.] Andrew Haenisch shared [I saw a video, but it was a talking heads news report rather than the drydock filling up.] |

|

| Interlake Steamship Co. posted Steven Sunde: Some one did a whoops!! Prop should be water further!! Lol Kim Lucas: Steven Sunde they need to have Ballast in to have the prop underwater. [Another illustration of why empty ships need to take on ballast water.] |

|

| safe_image for Freighter Ship Launched at Bayshipbuilding By far, the best story and photos from last week's launch of our new vessel, the M/V Mark W. Barker! |

The ship will ply Great Lakes waters, transporting raw materials such as road salt, iron ore, stone, sand and gypsum to manufacturers. But the ship’s unique cargo hold – a large square rather than the traditional V-shaped vessel – has been designed with the future in mind. That includes the transport of non-free-flowing bulk material such as wind-turbine blades.

“We went with a large, square hold to get more cubic and carry more tons per trip to lower our environmental impact, as well as carry some unique cargo,” Barker said.

The Mark W. Barker is adding capacity and not replacing any of the other nine lakers currently in Interlake’s fleet. Steel demand is strong, the aggregate business continues to grow and demand will increase for the carbon-efficient form of waterborne transportation.

|

| DuluthNewsTribune Aerial photo of the new Mark W. Barker, left, after it was floated at Fincantieri Bay Shipbuilding in Sturgeon Bay, Wisconsin, on Thursday, Oct. 28, 2021. Contributed / Interlake Steamship Company |

|

| Screenshot, a presentation with a professional voiceover starts at 0:35 and include some shots of the drydock being flooded. This was not the first time the ship went from land to water. It is the first time it has been pulled out without the intention for it to go back in for more building. The hull was pulled out at the beginning of the 2020-21 Winter to free up the dry dock for Winter layover repairs of other ships. It will go to another berth at the yard for more interior work. |

|

| 1 |

|

| 2 Tim Walter: They are two stoke engines. They are 16-710s make something like 4000-4500 hp each. [EMD designed, CAT built] |

|

| 3 Steven Cummings: Allen Bradley ControlLogix PLC's and a Centerline MCC...current state of the art. |

|

| 4 [Some comments call this the belt tunnel. I think that is the self-unloading belt on the left.] |

|

| 5 [A comments guesses that this is an emergency escape from the "engine control space."] |

|

| 6 B Tupper Upham: Well thank goodness somebody insulated the pilothouse ceiling...Bay, you finally got that right! |

|

| 7 |

|

| 8 |

.jpg) |

| safe_image for Introducing: The Mark W. Barker |

We are getting more excited by the day about our new build, the M/V Mark W. Barker!We thought we'd share with you all the deets on what makes our 639-foot Interlake beauty so unique for the Great Lakes.Not only is she the first ship to be built on the Lakes in more than 35 years, she has been thoughtfully designed - square-shaped cargo hold, large hatch openings and forward-mounted boom, to name a few. Those features along with her River Class length will make her the most versatile freighter in our fleet!

Front-end loaders and a skid steer were lowered into our new build, the 639-foot M/V Mark W. Barker last week.Our new River Class vessel is equipped with two Cat 938M front end loaders and one Cat 242D skid steer in her unique square-shaped, flat-bottom cargo hold.The loaders are stored in garages in the cargo hold, one forward and one aft. The loaders have buckets for pushing cargo into the unloading hoppers. The skid steer has a custom rotary broom to clean up the cargo hold at the end of an unload.Both are US EPA Tier 4 compliant.

|

| a |

|

| b [They have two frontend loaders, one for each side.] |

|

| c |

|

| d [That is not being driven off the rigging, the load was offset like that because most of the weight of an empty skid-steer is in the rear.] |

|

| e [Power broom attachment for the skid-steer.] |

Freefall!!!Today the crews at Fincantieri Bay Shipbuilding deployed the freefall lifeboat off our M/V Mark W. Barker for the first time as part of her testing to make sure she is fully operational before leaving the Sturgeon Bay, Wisconsin shipyard.Weighted down with water bags to simulate 30 crew members, the launch was successful and likely the first time anywhere on the Lakes that a stern lifeboat has been deployed.Our M/V Mark W. Barker is the first bulk carrier built on the Great Lakes in more than 35 years and the first U.S.-flagged vessel on the Lakes to be outfitted with a freefall lifeboat.

Janey Anderson shared a 2:56 video of the Mark W. Barker on the Cuyahoga River.

|

| 1:52 @ 1:24 "The M/V Mark W. Barker, the newest addition to the US flag-fleet on the Great Lakes is underway on her maiden voyage from Fincantieri Bay Shipbuilding where she has been under construction since the first cut of steel for her hull in August 2019. "The M/V Mark W. Barker is the first new ship to be built on the Great Lakes in nearly 40 years and the first new build for Interlake since 1981. We couldn't be more thrilled to have her truly operational with her crew aboard to begin her life of service moving essential cargos on the Lakes!" |

|

| 1 of 8 photos posted by Brian Caswell Mark W. Barker Unloading for the first time in Muskegon / 7-30-22 [To the left of the right-most cover you can see the bucket of one of the front-loaders that they use to help unload the bulk cargo. You can also see the holes in the cargo bay that lead to the unloading conveyor. According to a comment, they unloaded at the Verplank Dock.] |

|

| 1 of 3 photos and a video posted by Jeff Gushman Mark W Barker with a salute for her first downbound passage at the Blue Water Bridge. |

|

| 1 |

|

| 2 |

|

| Timothy Terry commented on Dave's post |

|

| Timothy Terry commented on Dave's post |

|

| James Torgeson posted Inside the cargo hold of the brand-new 639' Mark W. Barker, which will be christened in Cleveland on Thursday [Sep 1, 2022]. She's designed to carry both bulk cargoes like ore and project cargoes such as machinery. As such, her holds are square rather than sloped. The wheeled equipment helps move bulk materials to the grating that covers the unloading belt tunnel. The Cats reside in garages when the vessel is loaded. The gal who took this selfie is the Media Relations Director for Interlake Steamship, the Barker's owner. |

|

| 1st of 4 photos posted by Andrew Dean Detroit Mark W. Barker preparing to tie up for their first unload at Cliffs Dearborn yesterday. Detroit / Dearborn, Michigan Andrew Russell shared |

.jpg) |

| Interlake Steamship Company via Dennis DeBruler On Oct 27, 2022, the ship had a chance to showcase one of the new markets it was designed for: backhauling general cargo. In this case, it was about 4,000 tons of steel bars from the Port of Monroe to the Fraser Shipyard in Superior, WI. |

David Schauer posted four photos with the comment: "When the Mark W. Barker was at Fraser last week (10/29/2022) having steel bars unloaded, I couldn't help but recall that was the same spot where its self unloading boom was removed from the Victo (American Victory/Middletown) on June 11, 2018. The Victory had been bought by Algoma but never sailed under that flag, instead being sold for scrap overseas. Interlake bought the boom and as we know now it ended up on the MWB. Somewhat of an interesting "boatnerdy" occasion."

.jpg) |

| Dan Ross commented on David's post |

|

| 3:22 video @ 0:01 Mark W. Barker was BUILT to transport Cargill Salt! |

|

| sherwin-williams, Image courtesy of The Interlake Steamship Company, 1 of several photos A special coating was developed to help it cope with salt, its primary cargo. |

|

| safe_image for Box-shaped cargo hold among new ship's unique traits "Mark W. Barker will sail with a safer lifeboat, gender-specific changing rooms, and private staterooms for each crew member." "Two men walk near a partially open hatch on the Mark W. Barker on March 15. The vessel has fewer but larger hatch openings than a typical laker with a type of cover more commonly found on ocean-going vessels to give it more flexibility to carry cargos other than bulk materials.Steve Kuchera / Duluth News Tribune" Because of the rectangular cargo space, this 639' freighter has a capacity of 26,000 tons, which is more than its 767' fleet make Kaye E. Barker. The hatch covers are strong enough to hold containers. The bow has thicker steel to help sailing in ice conditions. "Twin, first-of-their-kind EMD-brand engines. “We have basically serial No. 1 and serial No. 2 for these engines,” Ott said, describing them as capable of 8,000 horsepower and the first 16-cylinder, Tier 4-compliant diesel engines ever put into service. Tier 4 status means the Mark W. Barker meets the strictest federal emissions standards. “There are some different systems … to make it Tier 4,” Ott said, describing “selective catalytic reduction.” “Basically, it’s a fancy way to say they spray a bunch of stuff into the exhaust that knocks the harmful stuff out of it,” she added." [So EMD gave up trying to meet Tier 4 requirements without using DEF.] |

.webp) |

| Interlake Steamship Co. via DuluthNewsTribune [Obviously, the freighter has a stern thruster.] |

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| Bill Kloss commented on Lance's post |

|

| Wayne Henderson commented on Lance's post |

More photos of Mark W. Barker in Cleveland

|

| 9:32 video |

Many photos were posted of the stuck freighter. Andrew had the best description and photo.

|

| 1 of 4 photos posted by Andrew Dean Detroit Well if you didn’t already know, The Mark W. Barker had to drop anchor to stop the ship safely after experiencing “loss of power and maneuverability”. The ship was assisted by tugs and brought down to Belle Isle Anchorage for further inspection. I have included the press release from Interlake below. “At approximately 0735 local time this morning, the M/V Mark W. Barker was transiting upbound in the Detroit River passing Belle Isle with a cargo of salt from Cleveland bound for Milwaukee, Wisconsin when it experienced a loss of power and maneuverability. The vessel turned to port unexpectedly and the Captain dropped the anchor before the bow grounded on the soft bank of the channel. No one was injured in the incident nor does there appear to be any risk of pollution or damage to the vessel. Working with the United States Coast Guard and with the assistance of a tug, the vessel was able back away from the bank and get underway to make its way to the Belle Isle Anchorage where the crew will continue to assess the vessel and work to determine the cause of the incident.” |

Note the timestamp in the lower-right corner in the video as to when it was refloated.

|

| 10:00 video @ 4:22 The tugboat Pennsylvania is pulling it offshore. |

|

| 0:46 video @ 0:18 From the cargo hold of the M/V Mark W. Barker unloading stone on the Cuyahoga River last night. Deckhands operate front-end loaders to push the last piles of cargo down onto the conveyor belt that travels underneath the holds and onto the unloading boom. [Several comments also had the reaction I had --- use and angled snow blade attachment instead of a bucket.] Jeremy S. Goldstein: Rick Tuttle when an offload is about to comence how does the conveyor belt get going when there are hundreds of tons of cargo in the hold? Kory Shimmin: Jeremy S. Goldstein gates underneath open and close allowing cargo onto the belt in certain sequences. This also reduces stress on the vessel having a controlled unload. |

2 of 6 photos posted by Stephen Sostaric. [It is docked at the end of the Indiana Harbor Canal.]

|

| 1 |

|

| 2 |

|

| 1 |

|

| 2 |

|

| 3 |

This would be unloading at Shelly Materials. The lift bridge is the NS/NKP Bridge and the road bridge is the I-90 George V. Voinovich Bridge.

|

| 4 |

%20Video%20_%20Facebook.png) |

| 0:24 video unloading salt [They need an angled snow plow attachment as well as a bucket.] |

|

| Bubba Dubs commented on the above source You can see the “garage” door open behind the payloader in this drone pic I took last year. |

|

| 1 of 8 drone photos of Mark W. Barker upbound to the steel mill |

|

| 1:43 video and 1:43 video Timelapse of our ship, Mark W Barker, going through the Soo Locks-upbound for Superior/Duluth. |

|

| Interlake Steamship Company posted 0:09 video Cool view of iron ore flowing into the belly of our M/V Mark W. Barker, loading at Cleveland Bulk Terminal earlier today. It really showcases the unique square-shaped cargo hold design on the 639-foot [195m] vessel, the newest and most versatile on the Great Lakes! 🎥: Eric Helder [1000' Lakers bring the ore to the dock from Lake Superior and then the short Mark W. Baker takes the ore up the river to steel mill.] |

No comments:

Post a Comment