The first part of the power plant building was built in 1925. In 1957, Unit #1 was replaced by Unit #6. It was 120mw and used the first commercial supercritical boiler and turbine in the world. This unit also pioneered reheating the steam to approach a thermal efficiency of 40%. (The subcritical state of art was 30%) "Edison’s Pearl Street Station in New York City operated at a maximum pressure of 160 pounds per square inch (psi). It had an efficiency of only 2.5 per cent and needed 10 pounds of coal to make one kilowatt of electricity. By the mid-1950s, pressures had reached thousands of pounds per square inch and power plants needed less than 0.7 pounds of coal to make each kilowatt of electricity. All of them, however, operated below the so-called 'critical' pressure of 3,208 psi and temperature of 705°F. That’s the point where water and steam have the same density, and the two act like they are the same substance." [HeartlandScience] In other words, the water never boils, it flashes to steam.

The unit was retired in 1979 and the power plant was dismantled in 1984. [asme] The turbine was preserved as a sculpture at AEP's headquarters building. [see post below]

|

Is the above an artist's conception? I haven't seen photos that contain a piece that looks like that. Units were added in phases and the later units were bigger. So either the uniform growth assumed by the above image did not happen or these four equally spaced stacks existed in a time period between some of the other photos.

|

slinger65 FlickrPhilo, Ohio Power plant 1924This shows the plant with units 1 & 2. In 1955 unit 1 was replaced by unit 6 which was an experimental unit and was down more then operating. |

|

| AEPretirees The caption for this photograph in our corporate archive reads: “Philo, which began operation in 1924, was the first plant in the world to reheat steam to do double duty in the process of generating electricity. It was the first plant to use steam at a temperature as high as 700 degrees F. and at a pressure as high as 600 pounds per square inch. |

Brennen Williams posted seven photos with the comment: "One of two turbine rotors on display outside of AEP’s headquarters in Columbus, Ohio. This rotor is from Philo #6, the first utility electrical generating unit to use steam at the supercritical pressure of 4500 psi. Also on display are the turbine and boiler builders plates."

Tim Stehle: Sweet to see AEP retains a bit of appreciation for these accomplishments, as I sit here imagining a double reheat for a 120MW unit when 100MW with no reheat was a “not long passed” milestone.

Dennis DeBruler: Tim Stehle For those of us who are trying to learn the history of the power industry, about when was this?

Tim Stehle: Dennis DeBruler Philo 6 was commissioned in 1957, though design engineering was started about 1952.

The unit itself wasn’t long lived versus others built in the same period, possibly BECAUSE Philo6 was so cutting edge.

Dennis DeBruler: Tim Stehle This unit was 120MW, but the metal in the turbine blades wasn't up to the task. "The unit was able to demonstrate operations at ultrasupercritical levels, but due to the lack of metals able to tolerate the extreme temperatures, the levels were unsustainable."

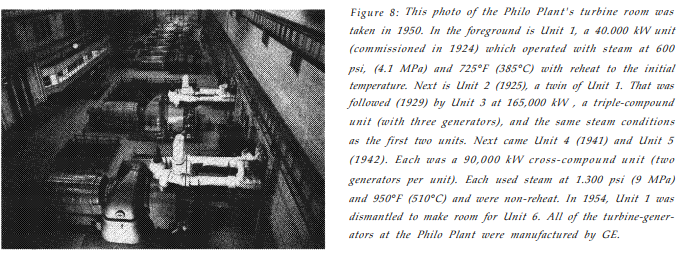

"Construction of the Philo Power Plant began in 1922 with the plant designed by Sargent & Lundy. Philo began commercial generation with Unit 1 in 1924. This unit initially had a nameplate capacity of 35 MW from General Electric's curtis turbine, but was raised to 40 MW after performing well on its test run. The turbine had a maximum pressure of 600 psi (4,100 kPa) and temperature of about 725 °F (385 °C). It was the first unit in the country that utilized steam reheat. Unit 1 was decommissioned and replaced by Unit 6 in 1957. Unit 2 was completed in 1925 and also had a nameplate capacity of 40 MW. The total cost of both units was $10 million. Unit 3 was completed in 1929 with a nameplate capacity of 165 MW. The total cost to costruct Unit 3 was $17 million. Units 4 and 5 were completed in 1941 and 1942 respectively and each had a nameplate capacity of 85 MW." (I presume Unit 3 was 65MW instead of 165MW.)

Tim Stehle: Dennis DeBruler Thx - your Philo 6 insight confirms my assumed generalization.

I agree on the quote having an embedded typo.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| Dennis DeBruler commented on Brennen's post Found it: https://www.google.com/.../data=!3m6!1e1!3m4... |

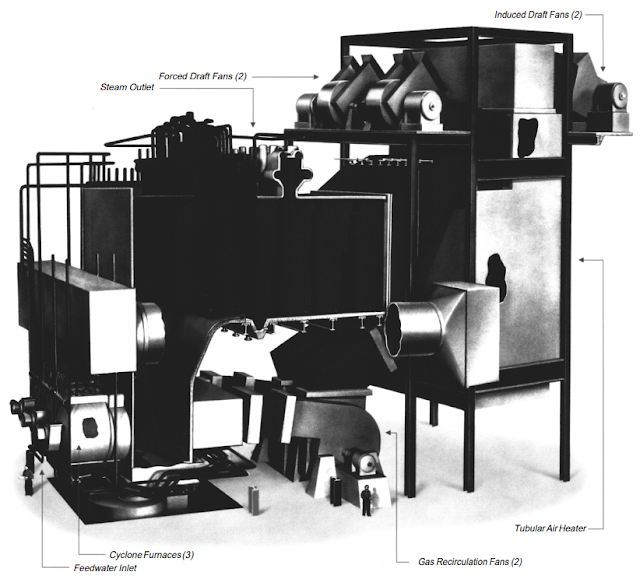

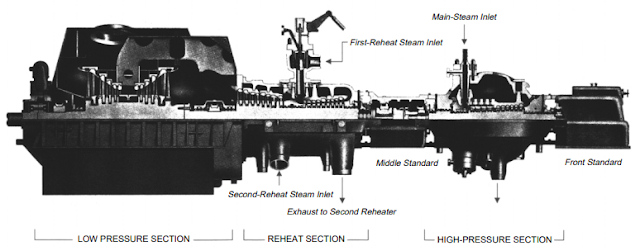

Both the feedwater inlet pressure of 5,500 pounds per square inch (psi) [37.9 mega Pascal (MPa)] and the turbine throttle pressure of 4,500 psi (31 MPa) constituted new "highs" in their respective classes and were almost double the steam pressure previously utilized for power production. The main steam temperature of 1,150 F (621 C) was 50 F (27.8 C) higher than economically achievable with then-existing technologies. The use of a double-reheat cycle [1,050 F (566 C) first reheat and 1,00 F (5338 C) second reheat] was a major innovation in the engineering of steam-electric power plants. The cyclone furnace design, integrated unit controls, feedwater chemical control, steam generator startup system, and feed-pump design were all uniquely developed for this pioneering unit. The unit's steam generator, designed and built by Babcock & Wilcox, was rated at 675,000 pounds per hour (8 5 Kg per second) at 4,500 psi (31 MPa) and 1,150 F (621 C) with a feedwater temperature of 525 F (274 C). The unit's turbine-generato designed and built by the General Electric Co., was a 3600-rpm, tandem-compound, double-flow turbine driving a 156,250 kva hydrogen-cooled generator. The next supercritical-pressure unit to enter commercial service in the United States, after Philo 6, was Philadelphia Electric Company's Eddystone Unit 1 in February 1960. [asme]

|

| asme-pdf, p11 [Note the little guy standing near the bottom center.] |

The leap from “subcritical” to “supercritical” steam at Philo 6 in the power generation industry was comparable to the jump from subsonic to supersonic flight, made 10 years earlier in the aviation industry. Breaking the critical steam barrier presented many engineering challenges analogous to those surmounted in breaking the sound barrier. [asme-pdf, p4]

|

| asme-pdf, p13 [Also used in a comment on the above post.] |

|

| asme-pdf, p12 |

"[Unit 6] was able to demonstrate operations at ultrasupercritical levels, but due to the lack of metals able to tolerate the extreme temperatures, the levels were unsustainable. To support the new unit, a 183 ft (56 m) smokestack was erected....When Philo began operations, the plant maintained a thermal efficiency of 24% consuming 14,000 BTU. Coal used by the plant came by either rail or river barge." [dguideapp]

|

| PowerMag Thermal efficiency improvement for economic gain has been an important power engineering endeavor for more than 250 years. The Newcomen steam engine appeared in 1750 and attained 0.5% efficiency. James Watt patented improvements in 1769 and achieved 2.7% efficiency by 1775, launching the Industrial Revolution. Watt limited operating pressure to about 0.034 MPa (5 psig). Richard Trevithick is credited with engine improvements that permitted increasing steam pressure to 1 MPa (145 psig), to achieve 17% thermal efficiency by 1834. American Electric Power’s (AEP) Philo Plant Unit 6 steam generator was the first commercial supercritical unit in service early in 1957 (Figure 1). Philo 6, a double-reheat design, delivered 120 MW, operating at 85 kg/s, 31 MPa, 621C/565C/538C (675,000 lb/h, 4,500 psi, 1,150F/1,050F/1,000F) and was supplied by The Babcock & Wilcox Co. (B&W). |

|

| Susan Morris Adams posted Philo Power Plant was a 510 megawatt (MW), coal power plant located in Philo in Muskingum County, Ohio. It was the first power plant in the United States to apply steam reheat and supercritical steam generator technologies for its turbines. The plant had six units and its operations were handled by Ohio Power, a forerunner of American Electric Power (AEP). It operated from 1924 until ceasing in 1975. The caption for this photograph in the AEP corporate archive reads: “Philo, which began operation in 1924, was the first plant in the world to reheat steam to do double duty in the process of generating electricity. It was the first plant to use steam at a temperature as high as 700 degrees F. and at a pressure as high as 600 pounds per square inch.” Kevin Sigmund: When I was a child in the 1960s my parents sometimes picnicked with me at a nearby roadside rest where you could also fish in the river. If the wind blew wrong you would get coal particulates on your lunch plate. Ed Reed shared History lesson for today👍 Barry Mottershead: It's not supercritical at 700/600 (not even close actually). Don Ryan: Barry Mottershead probably reheat pressure. Mainsteam was supercritical I believe. I imagine the article was written by a Journalist not a Power Engineer. Ed Reed shared again Jon Kishler: I went to high school a few blocks up the hill from there in an old WPA building that no AC but huge windows that we had to open during hot weather. If you were in a classroom on the plant side of the building you had to keep one eye on the smoke from the stacks and if the wind shifted and blew it your way you had to jump and run to close the windows or you would get covered in filthy black soot. |

No comments:

Post a Comment