|

| Bob Ciminel posted Homestead Works, Wheel & Axle. Joe Chiodo: In Mckees Rocks |

I remember seeing advertisements for Trinity Rail freight cars in the Trains Magazine.

I learned of this plant from a comment concerning this map.

|

| Bob Ciminel posted, part 1 James Torgeson: The original poster said he got the brochure during a 1975 tour of the Homestead Works. |

|

| Bob Ciminel posted, part 2 |

This plant was served by the Pittsburgh, Chartiers and Youghiogheny Railways, which was jointly owned by the Pennsy and Pittsburgh and Lake Erie. The PC&Y had a major engine servicing yard just south of this plant.

|

| StandardForgedProducts |

|

| StandardForgedProducts |

|

| StandardForgedProducts |

|

| StandardForgedProducts |

|

| 1948 Pittsburg West Quadrangle @ 1:24,000 |

|

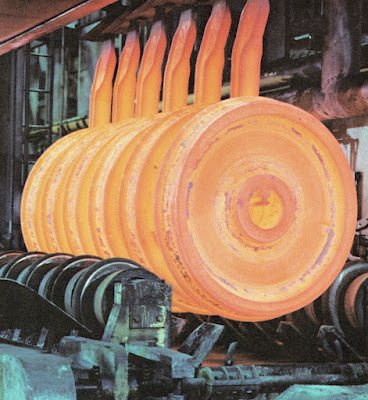

| Bob Ciminel posted USS Wheel & Axle mill, McKees Rocks, PA. Wilbert Fitch: Rolling foreman 40" Blooming Mill, USS Gary Works. Rolled the blanks for the Wheel Mill at Gary Works. And also rolled axle blanks for the axle mill at USS Gary Works at the 44 Blooming Mill. Abdu McCully: The Wheel mill building is still standing and being used for slab storage and the bloomer is just a skeleton building that holds utilities for the steel shops. Its amazing all the things Gary Works used to make but now only makes Sheet and Tin products and the 84 can roll 1 inch plate when or if needed. We used to make Rails Bars and Plate also. Michael Babbitt: My dad use to forge those at Standard Forge in East Chicago In. Joe Chiodo: They were rolled in the same mill that made smaller beams and piling but only went through the first section of the mill. A 25"×25" mold was used at the open hearth was used for this. George Gillespie: Now called McKees. Rocks Forging. Non union I was the last union President...that's the heat treating water quench. Real Bubba: Few domestic manufacturers left, railroads are cost conscience and most are purchasing imports. Greg Beyerl: Mckees Rocks Forging, Standard Forged Products. Trinity Industries. I worked there briefly in 2019 went back to sheet metal when they only paid 13.70 to start. Joseph Jencik: I labored at Wheel and Axle in the late 60s/early70s. While on 2nd shift, German engineers were called in to solve a casting problem with the dies on the newly installed line. The wheels were coming out with sprues on the outside hub, and when stacked for transport to the lathes for turning, would fall over and the line had to be stopped. After consultation with the shift boss, their temporary solution was to have me go to the tool shed, check out a big sledge hammer, a hard hat with face shield, and asbestos gauntlet gloves. I was told to go down the line when the wheels had lost their glow and hammer down any problematic sprues. I had to walk with the wheel and hammer; sometimes the handle would hit a sprue, once catching fire, and after about 6 wheels, the handle broke. They stopped the line, and told me to get 2 hammers. After the second one broke they shut down the line and went back to the drawing board. I was told to return the tools and go back to cleaning up cuttings around the lathes. Joseph Jencik: Wheel and Axle was the former Pressed Steel Car Co, site of the famous strike of 1909. |

16 photos Joe DiPietro: They still make train axels there.

No comments:

Post a Comment