(

Satellite, the store and its parking lot is the reuse of the land)

"Gradually, the

Rouge Plant surpassed Highland Park in size and importance, and in 1927 the final assembly line moved to the new facility, although Ford tractors and tractor components were made in Highland Park into the 1970s." [

miplace]

|

Joe's Friendly Tavern Empire posted

This day in Michigan history, 1913: Ford Introduces the Assembly Line on December 1, 1913, Henry Ford installs the first moving assembly line for the mass production of an entire automobile. His innovation reduced the time it took to build a car from more than 12 hours to two hours and 30 minutes. Ford’s Model T, introduced in 1908, was simple, sturdy and relatively inexpensive–but not inexpensive enough for Ford, who was determined to build “motor car[s] for the great multitude.” (“When I’m through,” he said, “about everybody will have one.”) In order to lower the price of his cars, Ford figured, he would just have to find a way to build them more efficiently. Ford had been trying to increase his factories’ productivity for years. The workers who built his Model N cars (the Model T’s predecessor) arranged the parts in a row on the floor, put the under-construction auto on skids and dragged it down the line as they worked. Later, the streamlining process grew more sophisticated. Ford broke the Model T’s assembly into 84 discrete steps, for example, and trained each of his workers to do just one. He also hired motion-study expert Frederick Taylor to make those jobs even more efficient. Meanwhile, he built machines that could stamp out parts automatically (and much more quickly than even the fastest human worker could). The most significant piece of Ford’s efficiency crusade was the assembly line. Inspired by the continuous-flow production methods used by flour mills, breweries, canneries and industrial bakeries, along with the disassembly of animal carcasses in Chicago’s meat-packing plants, Ford installed moving lines for bits and pieces of the manufacturing process: For instance, workers built motors and transmissions on rope-and-pulley–powered conveyor belts. In December 1913, he unveiled the pièce de résistance: the moving-chassis assembly line. In February 1914, he added a mechanized belt that chugged along at a speed of six feet per minute. As the pace accelerated, Ford produced more and more cars, and on June 4, 1924, the 10-millionth Model T rolled off the Highland Park assembly line. Though the Model T did not last much longer–by the middle of the 1920s, customers wanted a car that was inexpensive and had all the bells and whistles that the Model T scorned–it had ushered in the era of the automobile for everyone. |

|

MyAutoWorld

[This web site has lots of interior shots of the assembly plant.]

|

|

History's Mirror posted

In the 1930s, the Ford Highland Park Plant transitioned from its pioneering role in mass production to a specialized manufacturing hub, adapting to the evolving automotive industry. Though overshadowed by the newer River Rouge Plant, Highland Park remained crucial, producing Fordson tractors, commercial trucks, buses, and automotive trim. The decade saw innovation, such as the 1930 commercial exhibit in the former powerhouse, which displayed Ford’s commercial vehicles in staged outdoor settings, emphasizing their utility. Collaboration with Harry Ferguson led to the development of the Ford 9N tractor, featuring a revolutionary three-point hitch system that transformed agriculture. Architect Albert Kahn’s iconic “Crystal Palace” design, with its vast glass walls and skylights, still defined the plant, symbolizing industrial modernity despite partial demolitions, including the original smokestacks. Employment had dwindled from its 1920s peak, but the facility retained its legacy of efficiency. By the late 1930s, it pivoted toward wartime production, preparing for its World War II role in manufacturing Sherman tanks and aircraft components. Though no longer the heart of Ford’s operations, Highland Park’s blend of historical significance and adaptive reuse underscored its enduring impact. Recognized as a Michigan State Historic Site in 1956 and a National Historic Landmark by 1978, the plant stood as a testament to industrial innovation, bridging Henry Ford’s assembly line legacy with the demands of a changing world. |

Thomas Wentzel

shared two photos:

|

1

Bob Sherwood: PCC's after retirement. Some numbered in the 21-- series ready for shipment while others awaiting repaint into Mexico City colors and numbers. |

|

| 2 |

|

DetroitHistorical

This was the second of three plants that Ford built to assemble the Model T, and it began operation on Jan 1, 1910. It was the plant that pioneered the use of an assembly line and a wage of $5 for an 8-hour day. |

|

Photo via ArtsAndCulture and TheHenryFord

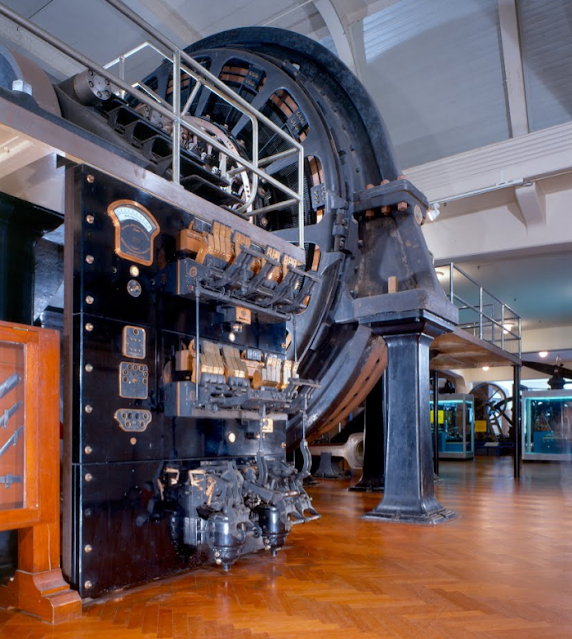

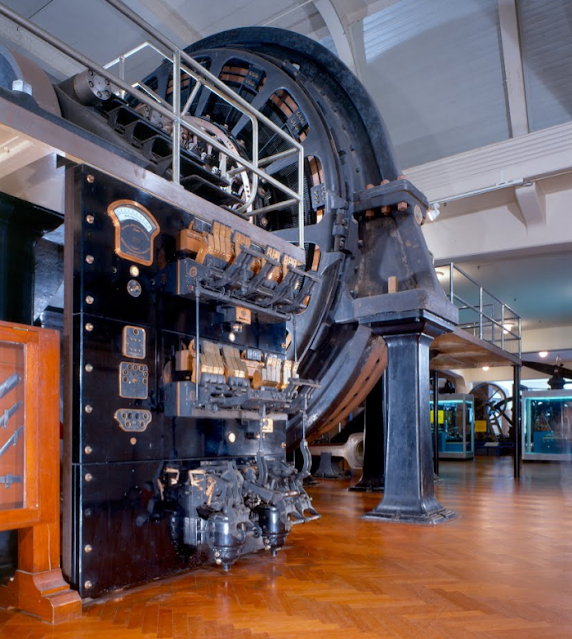

This is one of the nine generators that were installed between 1916 and 1919. They were retired by 1926 when electricity was fed from Ford's River Rouge plant.

[The big wheel with some visible copper was a Crocker-Wheeler generator rated at 4474kw DC at 250v. The bigger wheel behind it was the 100-ton, 18' flywheel.[ModelTfordFix] ] |

This is a better view of the flywheel and shows one of the engines that drove it. (I don't know if this is the steam side or the gas side.

|

ArtifactsInAction

“This machine, 82 feet long, 46 feet wide, and weighing 750 tons, is one of nine that powered the Ford Motor Company's Highland Park plant while Model Ts were being manufactured there. Together, the nine machines generated 53,000 horsepower. Each had a gas engine and a steam engine mounted on either side of a 4,000-kW DC generator. The gas engines being more efficient than the steam-driven units but less regular in speed, provided economy and power; the steam engines provided regulation and reliability. At the time the units were installed at Highland Park around 1915, they created quite a stir in engineering circles. They were generally regarded as highly innovative and economical means of supplying industrial power."

Bryan, Ford R., and Sarah Evans. Henry's Attic: Some Fascinating Gifts to Henry Ford and His Museum. Dearborn, MI: Ford, 1995. Print.

|

|

ModelTfordFix

The generator hall was 400' long.

Here we can clearly see the two engines on either side of the generator and flywheel. Because the steam engine was compound, each unit has three cylinders: high pressure at 36", low pressure at 72" and gas at 42". All of the cylinders had a stroke of 72". |

|

| 1924 Detroit Quadrangle @ 1:62,500 |

|

16:09 video @ 0:24

Henry Ford's Hybrid GasSteam Engine |

No comments:

Post a Comment